Acetylacetone shrinkage isonicotinyl hydrazine molybdenum complex and preparation method thereof

A technology of isoniazid and acetylacetone, applied in the field of acetylacetonate isoniazid hydrazide molybdenum complex and preparation thereof, can solve problems such as no molybdenum Schiff base complex, and achieve excellent catalytic performance and reaction conditions Gentle, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

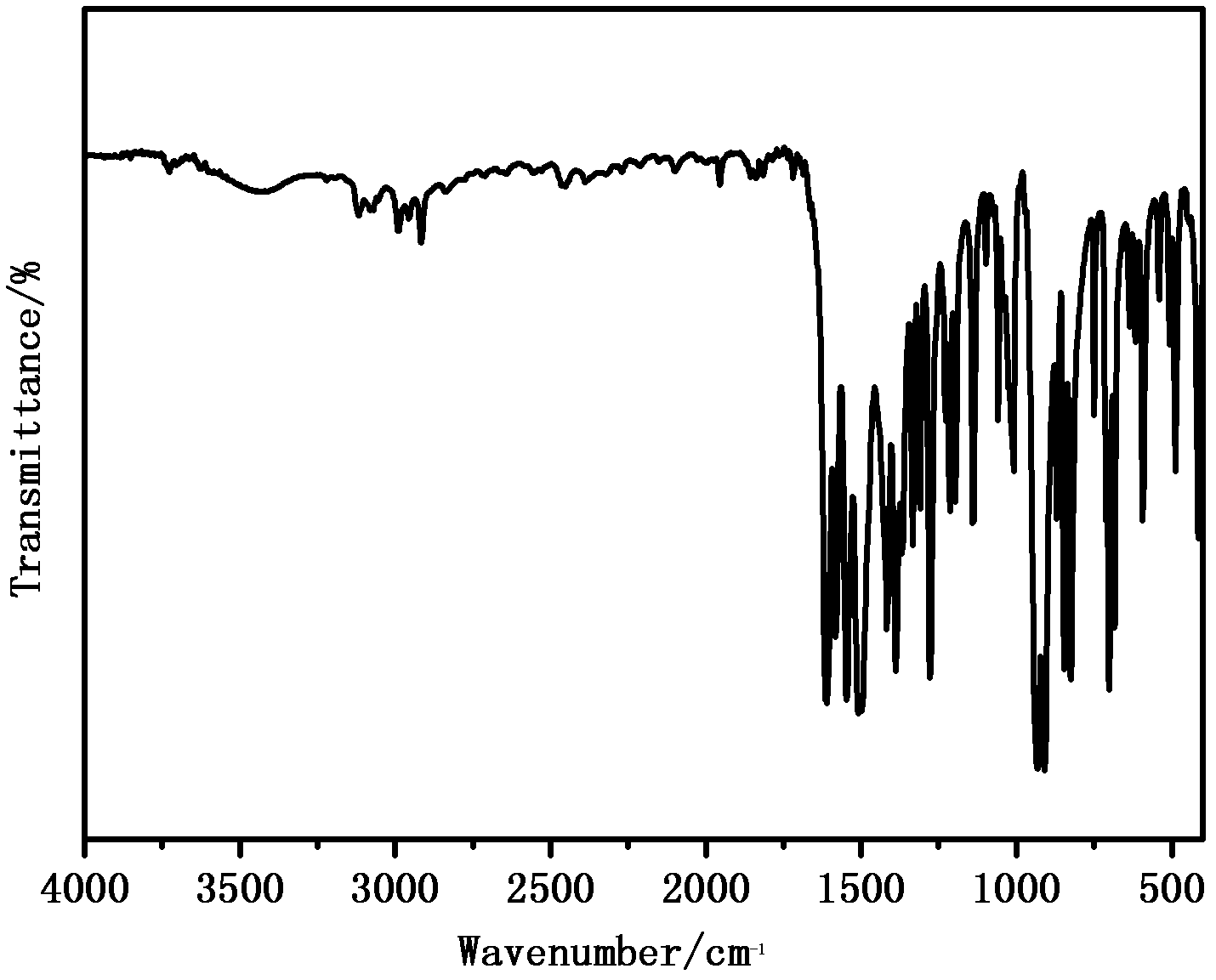

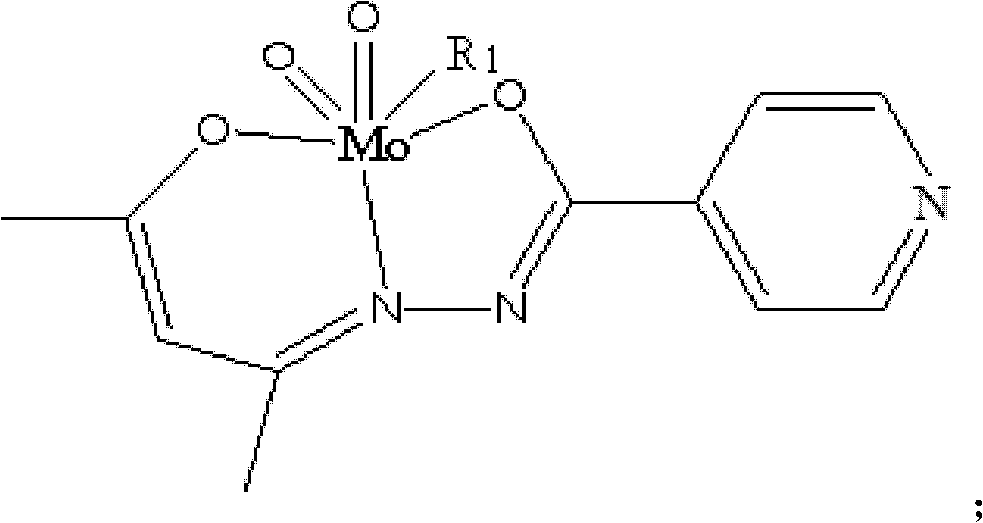

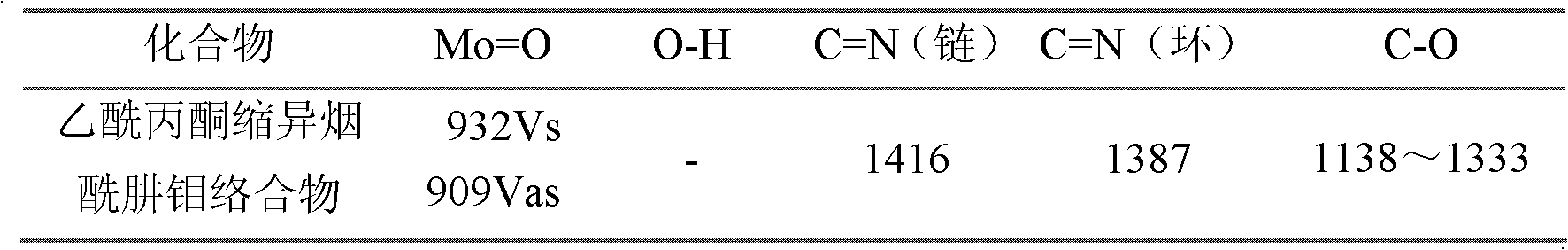

[0018] Weigh 10 mmol of isoniazid, put it into a round-bottomed flask (50 ml) containing 20 ml of absolute ethanol, heat and stir at 75°C, add 12 mmol of acetylacetone after the complete dissolution of isoniazid, and stir for 2 Add 10 millimoles of molybdenum acetylacetonate after 1 hour, orange-red powder is precipitated, continue to heat and stir for 2 hours, then filter with suction, wash with ethanol and dry in vacuum at 40°C to obtain an orange-red powder product. Its structural formula is as follows, and its infrared analysis spectrum is shown in figure 1 .

[0019]

Embodiment 2

[0021] Weigh 10 mmol of isoniazid, put it into a round bottom flask (50 ml) containing 20 ml of pyridine, heat and stir at 75°C, add 12 mmol of acetylacetone after the isoniazid is completely dissolved, and stir for 2 hours Add 10 millimoles of molybdenum acetylacetonate, orange-red powder precipitates out, continue to heat and stir for 2 hours, filter with suction, wash with pyridine, and dry in vacuum at 40°C to obtain the product. Its structural formula is as follows, and its infrared analysis spectrum and figure 1 resemblance.

[0022]

Embodiment 3

[0024] Put tert-butyl hydroperoxide, n-propanol and the molybdenum complex of isoniazid acetylacetonate synthesized in [Example 1] into a high-pressure reactor, seal the reactor and start heating and stirring. When the preset 100°C is reached, the high-pressure pump pumps in propylene, and the amount of propylene is determined by the pumped volume. Reaction timing, after reaching 2 hours, take off the reactor, cool to 10-15°C with ice water, and take the liquid phase into a frozen sampler. Continue to freeze the sampler at -20°C for 30 minutes, then unscrew the air valve, release the propylene in the sampler slowly, open the sampler, quickly transfer the remaining liquid to the chromatographic sampling bottle, seal it, and perform chromatographic analysis.

[0025] Reaction conditions: reaction temperature 100°C, reaction time 2 hours, rotating speed 540rpm, tert-butyl hydroperoxide (TBHP) addition 70 millimoles, n-propanol addition 50 millimoles, catalyst addition 0.1 millimo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com