Master device of large-power high-energy-saving micro-emission internal combustion engine utilizing explosive energy to promote, activate and force combustion

An internal combustion engine, micro-emission technology, applied in engine components, engine control, combustion engines, etc., can solve the problem of less engines, achieve stable performance, environmental protection, ultra-low emissions, and convenient manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

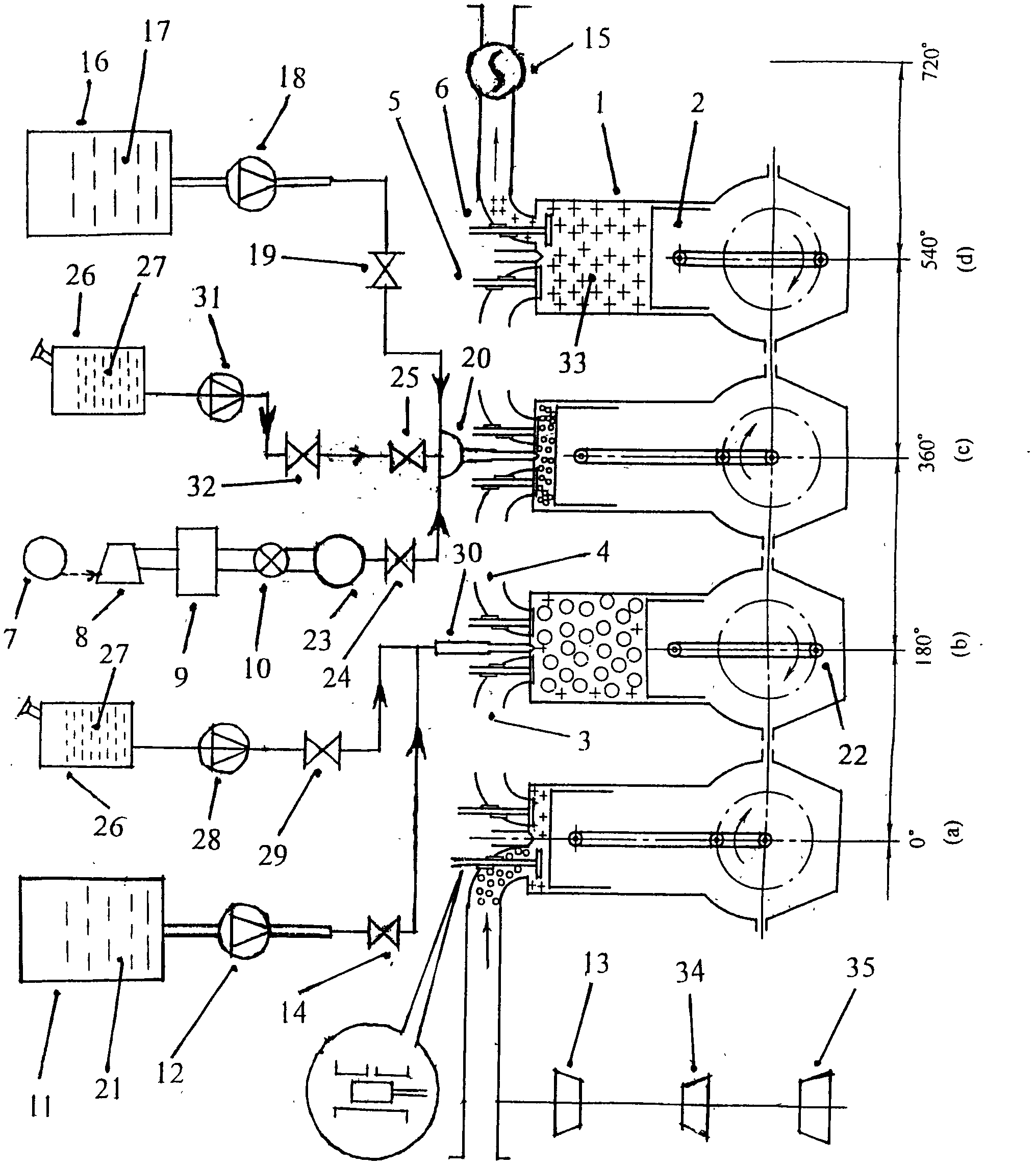

[0010] exist figure 1 Among them, the piston (2) is set on the high-pressure cylinder (1), the shutter intake valve (5) and the shutter exhaust valve (6) are connected to the upper part of the high-pressure cylinder (1), and the high-pressure cylinder (1) is set High-temperature, ultra-high reaction rate, high-mixing, ultra-high-speed combustion promotion and ignition forced combustion chamber (33), a connection shutter intake valve (5) is set on the intake passage (3), and a connection shutter row is provided on the exhaust passage (4) Air valve (6). The upper part of the high-pressure cylinder (1) is provided with a high-pressure injector (30), and the high-pressure injector (30) is provided with a water-alcohol mixed liquid tank (11), a high-pressure pump (12), and a high-pressure input of the water-alcoholic mixed liquid. A controller (14) is provided with a turbine (13), a small compressor (34), and a large compressor (35) on the exhaust passage (4). One end of the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com