Etching method of semiconductor structure

A semi-conductor technology to be etched, which is applied in semiconductor/solid-state device manufacturing, discharge tubes, electrical components, etc. It can solve the problem of slow etching rate and achieve uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

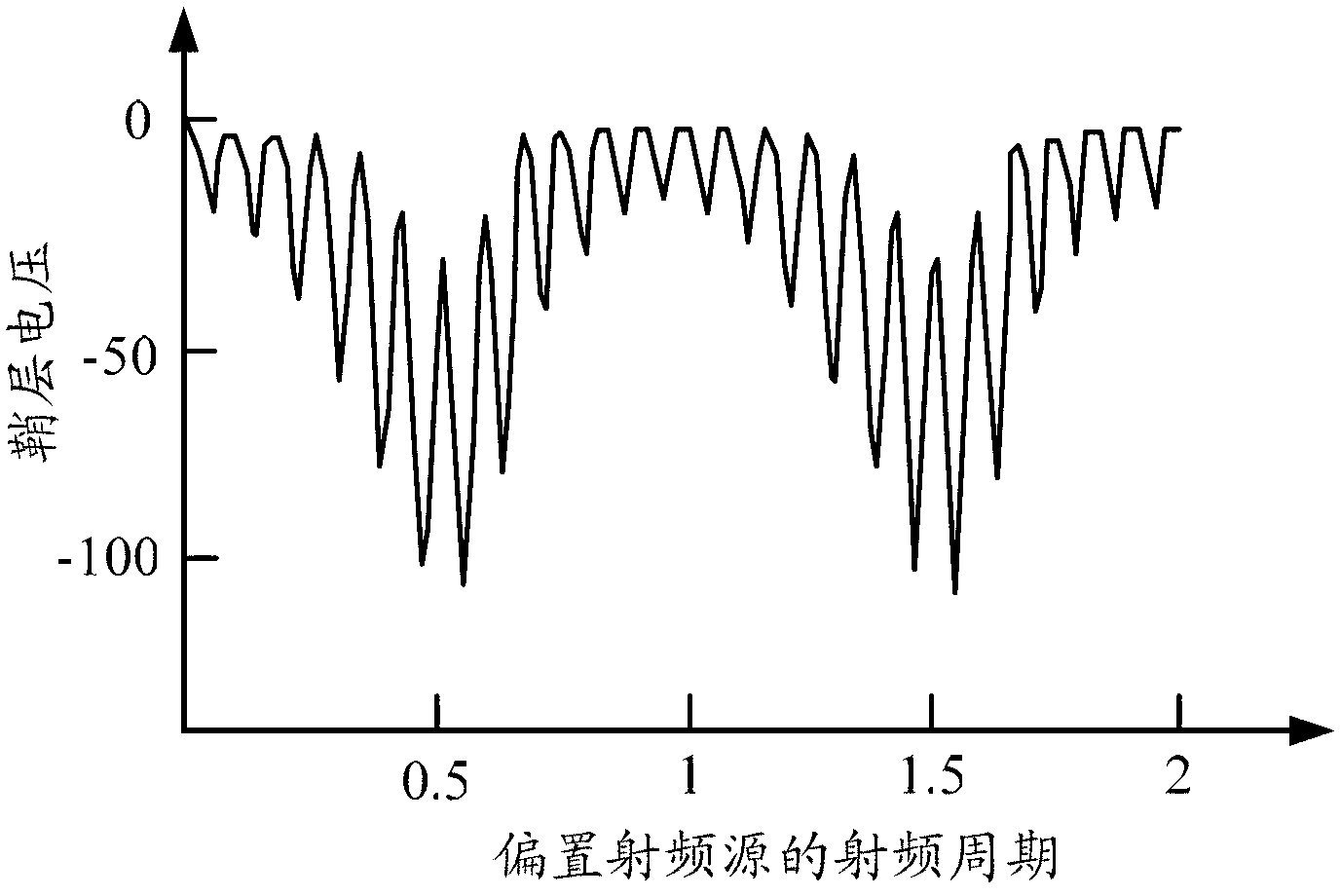

[0028] Since the positive ions and electrons in the plasma have different angular distributions, the positively charged positive ions tend to gather at the bottom of the etching opening formed by etching the material layer to be etched, and the continuous bias will make the etching The positively charged ions at the bottom of the etched opening are continuously gathered, and the micro-electric field formed by the positively charged ions will affect the trajectory of the subsequently arriving positively charged ions, so that the sidewall of the etched opening is over-etched, and the The etch rate at the bottom of the etched opening is slower, affecting the overall etch rate.

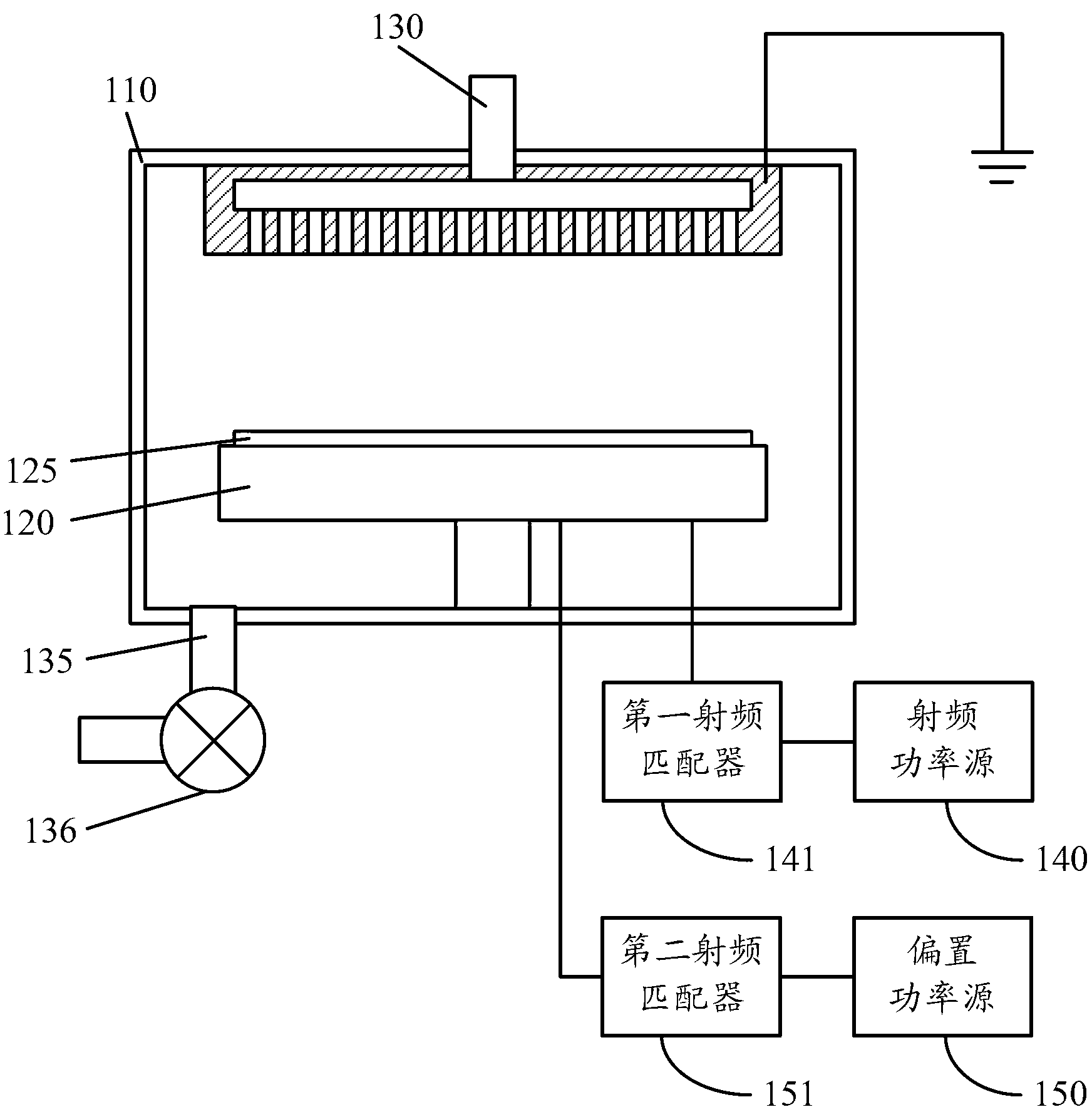

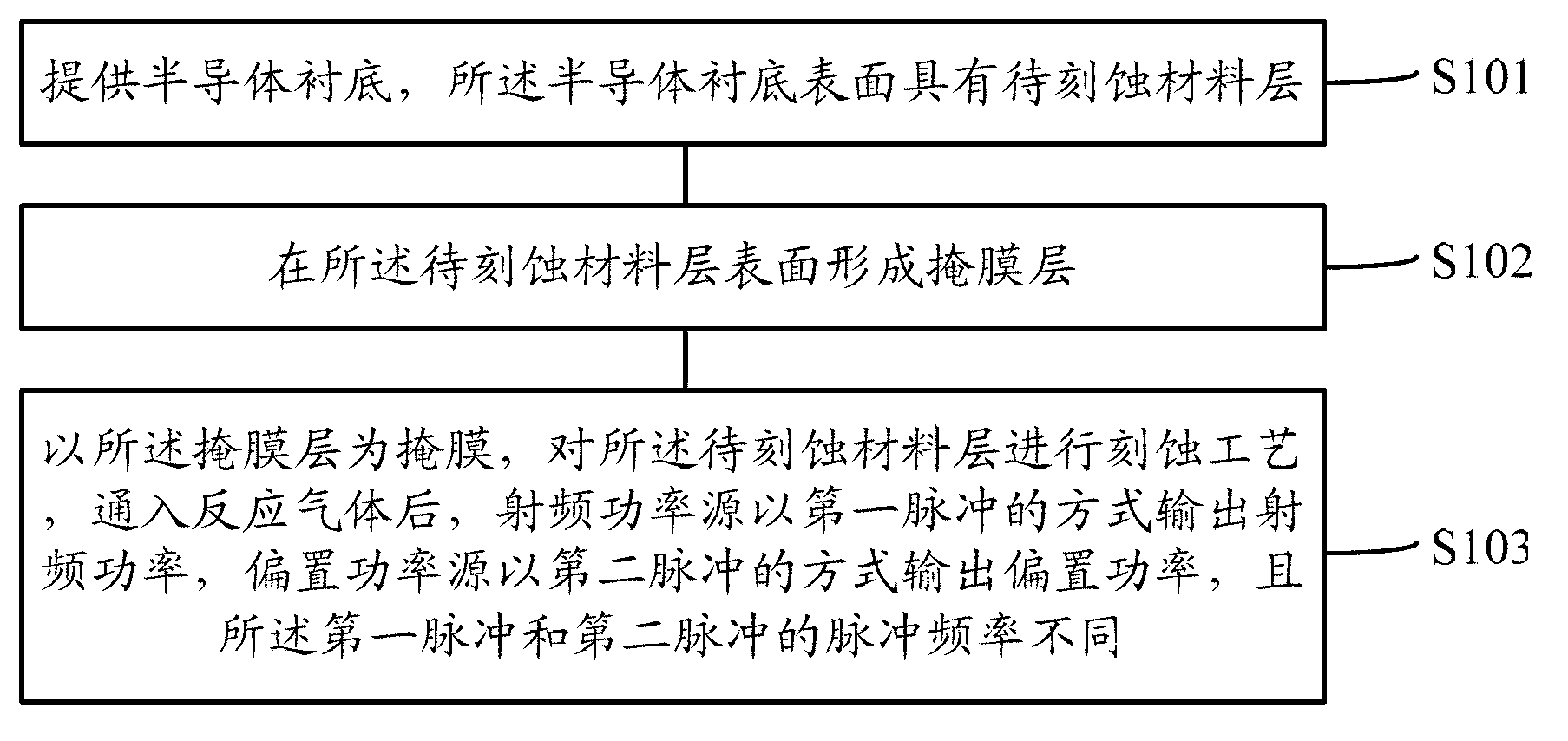

[0029] To this end, an embodiment of the present invention provides a method for etching a semiconductor structure. After the reactive gas is introduced, the RF power source outputs RF power in the form of a first pulse, and the bias power source outputs RF power in the form of a second pulse. The bias po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com