Reinforced-denitrification MBR (membrane bioreactor) sewage treatment method

A sewage treatment method and denitrification technology, which are applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Efficient removal of phosphorus, difficult to treat with urban sewage, etc., to achieve the effect of improving sedimentation effect, strong activity, and stable denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

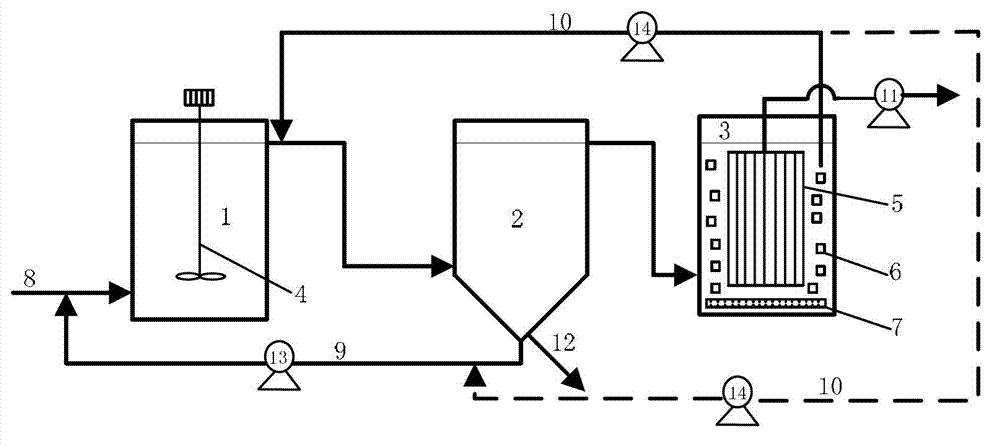

[0036] Example 1: The concentration of ammonia nitrogen in the incoming water is not high, and the sewage treated by facilities such as fine screens, grit chambers, fine screens (membrane screens) and 300% to 400% of the sludge in the return sedimentation tank enter the anoxic tank 1 , the hydraulic retention time is 4.0-5.0h, the sludge concentration is 4.5-6.0g / L, the outflow of the anoxic tank and the 200%-400% reflux membrane tank nitrification liquid enter the ② sedimentation tank, the residence time is 4.0h, the sedimentation tank part Sludge backflow, part of the sludge discharge, the outflow of the sedimentation tank enters the ③ membrane tank, the hydraulic retention time is 2.0-3.0h, and 10%-12% of embedded nitrifying bacteria are added, and the embedded nitrifying bacteria are intercepted at the return flow of the nitrifying liquid The device uses a pump to intermittently suck water out of the membrane filament, and the water out is discharged or reused.

Embodiment 2

[0037] Example 2: When the concentration of ammonia nitrogen in the incoming water is high, the sewage treated by facilities such as fine screens, grit chambers, fine screens (membrane screens) and 200% to 400% of the sludge in the return sedimentation tank and about 100% The nitrifying liquid in the backflow membrane tank enters the anoxic tank, the hydraulic retention time is 5.0-6.0h, the sludge concentration is 5.0-8.0g / L, the outflow of the anoxic tank and 300%-400% of the nitrifying liquid in the backflow membrane tank enters the ② Sedimentation tank, the residence time is 4.0h, part of the sludge in the sedimentation tank is refluxed, part of the sludge is discharged, the outflow of the sedimentation tank enters the ③ membrane tank, the hydraulic retention time is 2.5-3.5h, and 12%-15% of embedded nitrifying bacteria are added , A carrier interception device is installed at the reflux of the nitrifying liquid, and the pump intermittently sucks the water out of the membra...

Embodiment 3

[0038] Example 3: When the phosphorus content in the incoming water is high and the phosphorus in the effluent cannot meet the standard, the sewage treated by fine screens, grit chambers, fine screens (membrane screens) and other facilities and 200% to 400% of the sludge in the return sedimentation tank (and about 100% of the nitrifying liquid in the backflow membrane tank) enters ① the anoxic tank, the hydraulic retention time is 4.0-6.0h, the sludge concentration is 4.5-8.0g / L, the outflow of the anoxic tank and the reflux of 200%-400% The nitrification liquid in the membrane tank enters the ② sedimentation tank, the residence time is 4.0h, part of the sludge in the sedimentation tank is refluxed, and part of the sludge is discharged, and the outflow of the sedimentation tank enters the ③ membrane tank, and the chemical phosphorus removal agent is added to the water inlet, and the hydraulic retention time is 2.0 ~ 3.5h, add 10% ~ 15% of embedded nitrifying bacteria, install c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com