P2O5-BaO-Na2O-K2O-Y2O3-Eu2O3 glass ceramic and preparation method thereof

A technology of p2o5-bao-na2o-k2o-y2o3-eu2o3, 1.p2o5-bao-na2o-k2o-y2o3-eu2o3 is applied in the field of glass ceramics and its preparation, and achieves high thermal conductivity, low production cost and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: The raw materials are weighed according to the mole percentage of each component in the matrix glass, respectively: P 2 o 5 : 45, BaO: 24, Na 2 O: 7.5, K 2 O: 8.5, Y 2 o 3 : 14.55, Eu 2 o 3 : 0.45, mix accurately weighed 30g of raw materials evenly, pour into a platinum crucible to melt, the melting temperature is 1510°C, keep warm for 0.5 hours, pour the molten glass on the preheated stainless steel mold, and then put Put it into a muffle furnace for annealing, the annealing temperature is 600°C, heat treatment the obtained glass, the heat treatment temperature is 700°C, the heating rate is 10°C / min, the holding time is 1 hour, turn off the power and cool to room temperature with the furnace, then take it out , the main crystal phase is Y(PO 3 ) 3 and subcrystalline phase as NaPO 3 、Ba(PO 3 ) 2 , Y 2 o 3 glass ceramics.

Embodiment 2

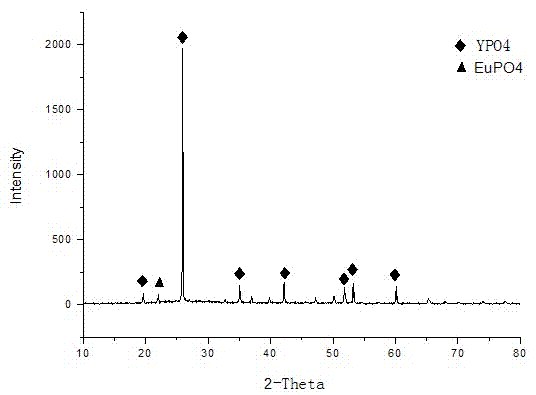

[0021] Embodiment 2: The raw materials are weighed according to the mole percentage of each component in the matrix glass, which are respectively: P 2 o 5 : 45, BaO: 24, Na 2 O: 7.5, K 2 O: 8.5, Y 2 o 3 : 14.55, Eu 2 o 3 : 0.45, mix accurately weighed 30g of raw materials evenly, pour into a platinum crucible to melt, the melting temperature is 1510°C, keep warm for 0.5 hours, pour the molten glass on the preheated stainless steel mold, and then put Put it into a muffle furnace for annealing, the annealing temperature is 600°C, heat treatment the obtained glass, the heat treatment temperature is 1000°C, the heating rate is 10°C / min, the holding time is 1 hour, turn off the power and cool to room temperature with the furnace, then take it out , the main crystal phase is Y(PO 3 ) 3 and subcrystalline phase for YPO 4 、Ba(PO 3 ) 2 , Y2 o 3 glass ceramics.

Embodiment 3

[0022] Embodiment 3: The raw materials are weighed according to the molar percentage of each component in the matrix glass, respectively: P 2 o 5 : 45, BaO: 24, Na 2 O: 7.5, K 2 O: 8.5, Y 2 o 3 : 14.55, Eu 2 o 3 : 0.45, after mixing 30g of raw materials that have been accurately weighed evenly, pour it into a platinum crucible and melt it. The melting temperature is 1510°C. Put it into a muffle furnace for annealing, the annealing temperature is 600°C, heat treatment the obtained glass, the heat treatment temperature is 1300°C, the heating rate is 10°C / min, the holding time is 1 hour, turn off the power and cool to room temperature with the furnace, then take it out , the main crystal phase is Y(PO 3 ) 3 and subcrystalline phase for YPO 4 glass ceramics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com