Styrene-butadiene copolymer as well as preparation and applications thereof

A technology of butadiene and styrene, applied in the field of styrene-butadiene copolymer and its preparation, can solve problems such as restricted mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

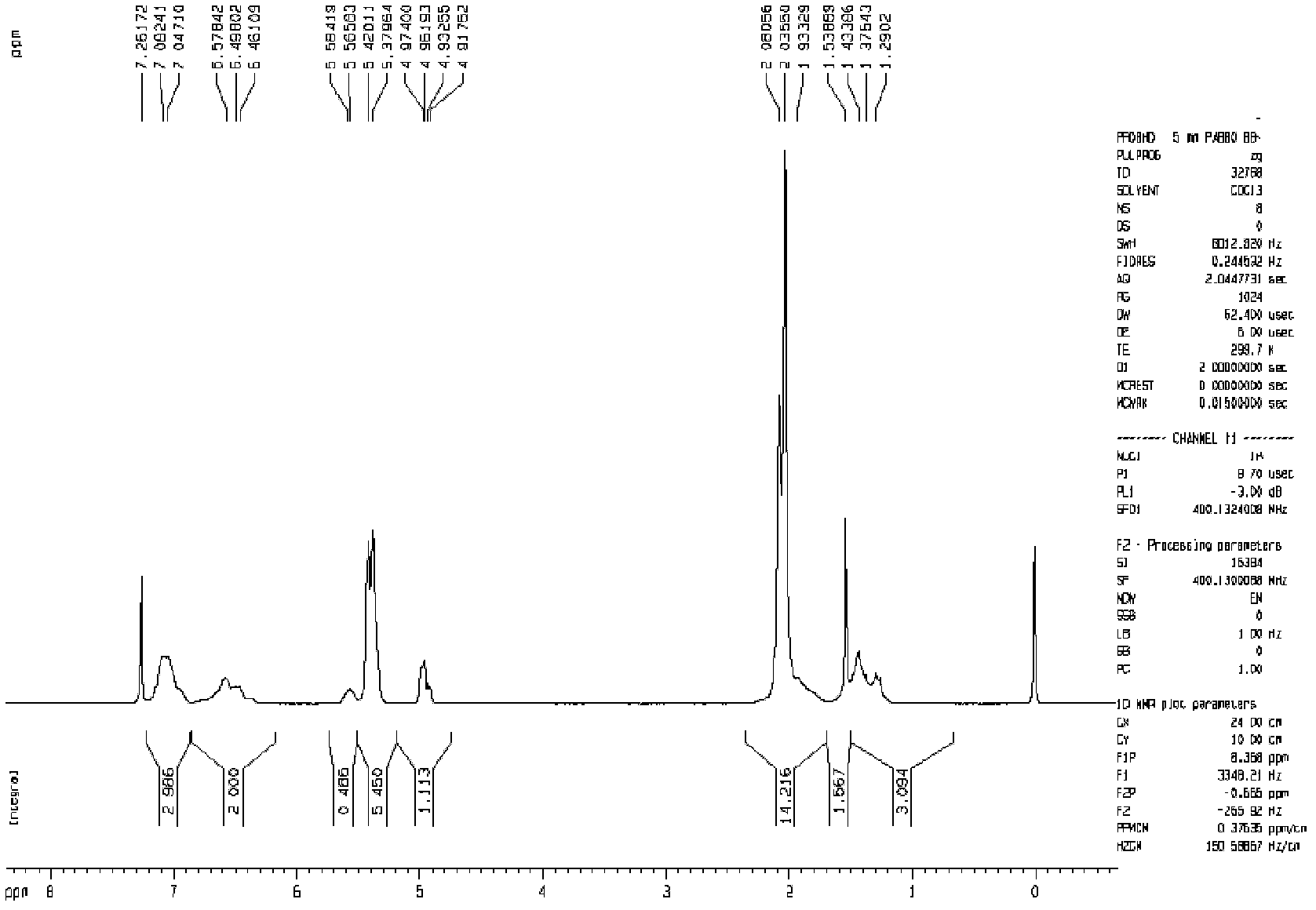

Embodiment 1

[0066] Add 2.5 liters of hexanaphthene and raffinate mixture (the mixing ratio of hexanaphthene and raffinate is 9: 1) in the 5 liters of polymerizers that purify through nitrogen, wherein be 300mg / kg with the content in polymerization solvent The amount of tetrahydrofuran was added. The temperature of the mixture was raised to 50° C., 100 g of styrene was first added, and then 1.0 mmol of n-butyllithium was added to initiate the reaction. After stirring and reacting for 20-60 minutes, 150 g of butadiene was added to the active polymer, during which the reaction temperature was controlled at 40-115° C., stirred for 20-60 minutes, and then 5 ml of water was added to terminate the reaction. Add 0.2-0.6% of antioxidant based on the mass of the polymer to the reaction mixture, and stir for 5 minutes. Finally, the product is added to a mixture of steam and water, the solvent is evaporated, and the polymer is isolated as a solid suspended in water. The solid is separated, squeezed...

Embodiment 2

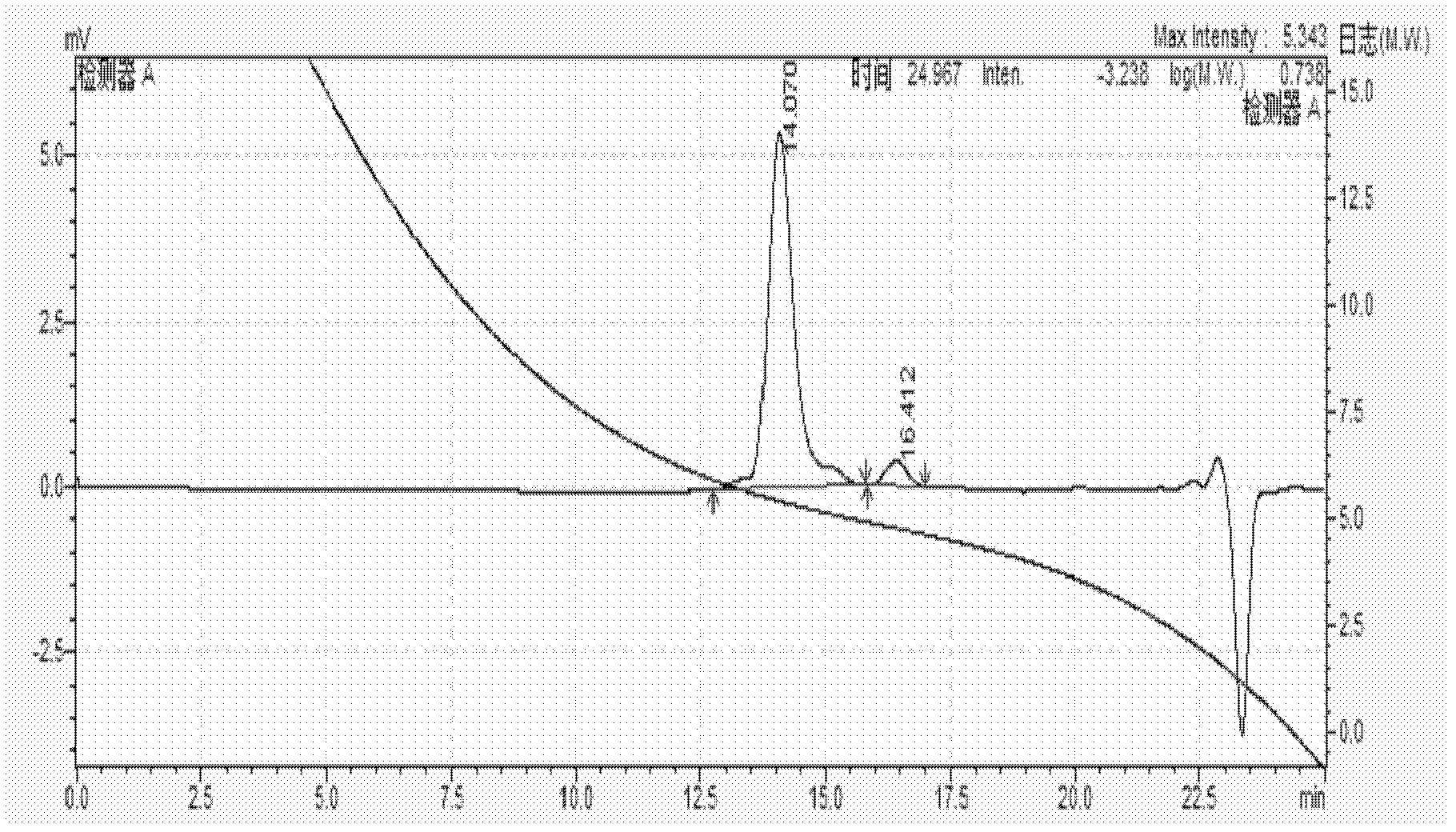

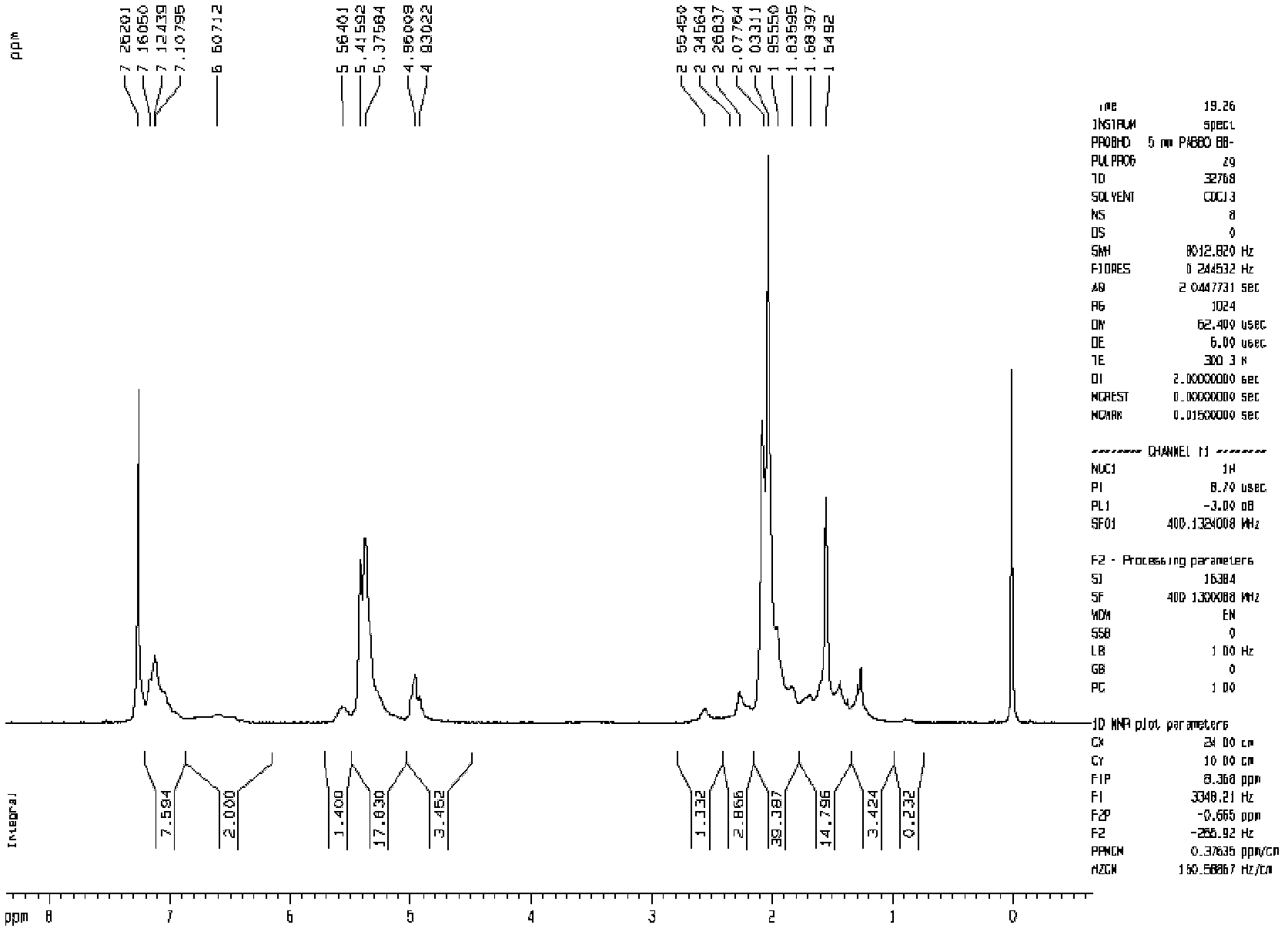

[0073]Add 2.5 liters of hexanaphthene and raffinate mixture (the mixing ratio of hexanaphthene and raffinate is 9: 1) in the 5 liters of polymerizers that purify through nitrogen, wherein be 300mg / kg with the content in polymerization solvent The amount of tetrahydrofuran was added. The mixture was warmed to 50° C., and 2.15 mmol of n-butyllithium were added. After stirring for 5 minutes, 162.6 g of butadiene monomer was added into the polymerization tank, during which the reaction temperature was controlled at 40-110° C., and the reaction was carried out for 20-60 minutes. Then add 75g styrene in the reactor, react and carry out 20-60 minute. Then add 12.4g of butadiene to the reaction kettle, react for 5-30 minutes, finally add 5ml of coupling agent silicon tetrachloride, react for 10-40 minutes, add 0.2-0.6% anti-corrosion compound based on the mass of polymer in the mixture Oxygen, stir for 5 minutes. Finally, the product is added to a mixture of steam and water, the so...

Embodiment 3

[0083] The styrene-butadiene copolymer of the linear structure of 0.48 kilograms of embodiment 1 of the present invention is mixed with 6 kilograms of general-purpose polystyrene, joins in twin-screw extruder and causes HIPS particle, and the temperature of twin-screw machine is 140°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com