Preparation method of hexagonal phase boron nitride film

A technology of phase boron nitride and boron nitride, which is applied in the field of preparation of boron nitride thin films, can solve problems such as potential safety hazards, and achieve the effects of good safety, excellent insulation properties and flatness, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

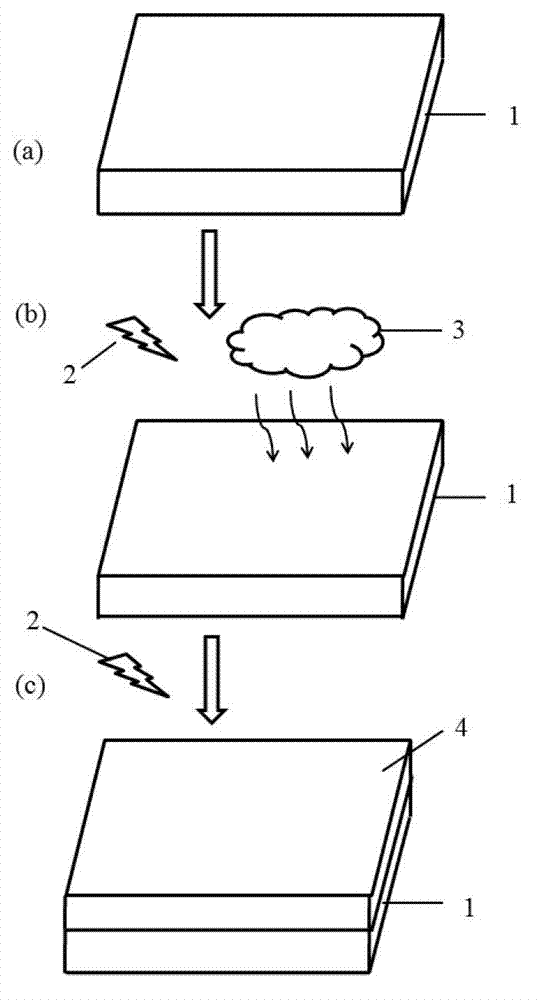

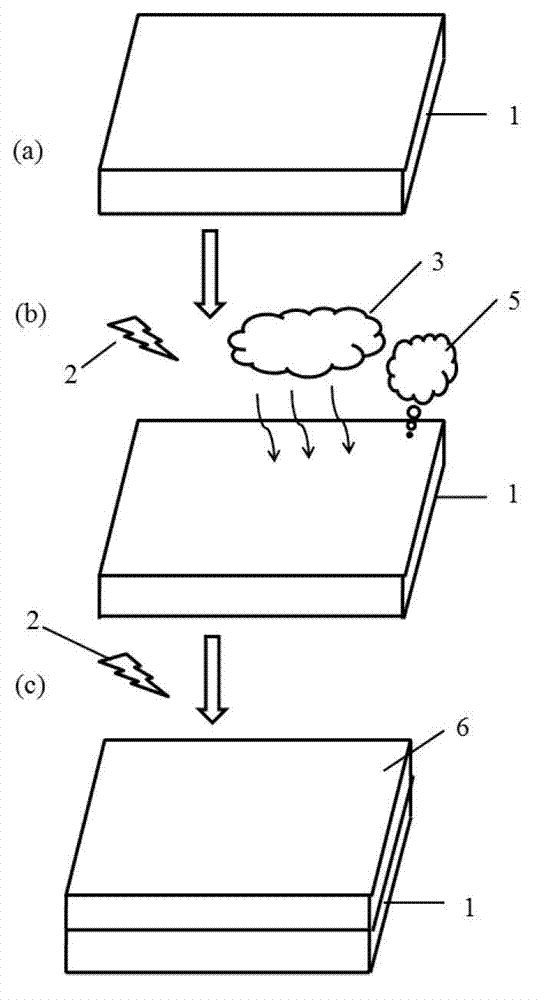

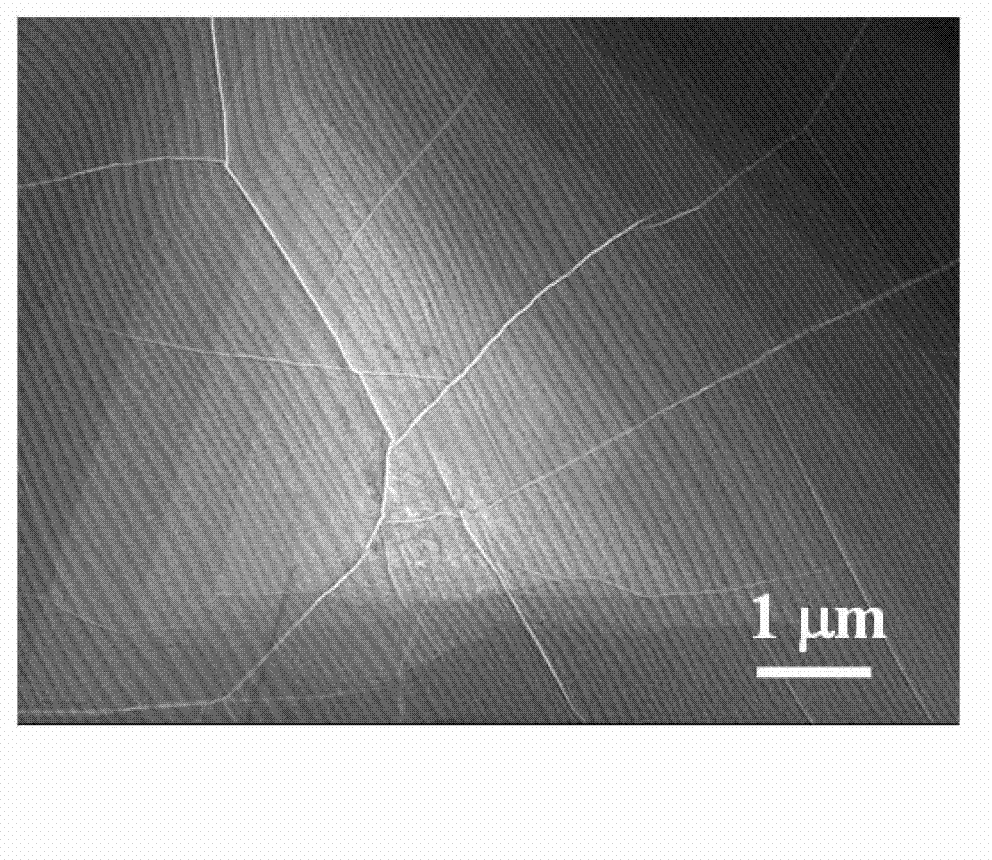

[0038] Such as figure 1 shown in 1×10 -8 Under the background vacuum of Pa, hexagonal boron nitride thin films were prepared on copper sheets by electron beam deposition. Firstly, the copper sheet ( figure 1 In part a) heat treatment for 2 hours; then in N 2 / Ar (50sccm / 80sccm) atmosphere (working pressure is about 2×10 -2 Pa), and when the substrate temperature was 850°C, the boron powder was evaporated by the electron beam from the electron gun, and the boron atomic flow was evaporated at a rate of 1.0nm / min ( figure 1 middle part b); keep the same temperature and atmosphere conditions, heat treatment for 5 minutes ( figure 1 Part c in the middle), and finally lower the temperature to 20°C at a cooling rate of 200°C / min to obtain a hexagonal boron nitride film with uneven layers (scanning electron microscope image as image 3 shown).

Embodiment 2

[0040] at 1×10 -6 Under the background vacuum of Pa, the graphene film / SiO 2 Hexagonal boron nitride film was prepared on the substrate composed of / Si: under the condition of the substrate temperature of 20 ℃, the N 2 / Ar (20sccm / 50sccm), the working pressure is about 10Pa, and the boron nitride target is sputtered at a sputtering rate of about 0.01nm / min; then in the same atmosphere, the temperature is raised to 1100°C for 45 minutes; finally With the cooling rate of 400 DEG C / min, the temperature is reduced to 20 DEG C, thereby obtaining a single-layer hexagonal phase boron nitride film on the graphene film (Raman spectrum such as Figure 4 shown in curve a).

Embodiment 3

[0042] at 2×10 -6 Under the background vacuum of Pa, the method of magnetron sputtering was used on Ni / Al 2 o 3 Hexagonal boron nitride thin films were prepared on substrates composed of: the NH 3 / Ar (20sccm / 100sccm) working pressure is about 100Pa atmosphere, under the condition that the substrate temperature is 880°C, sputter the boron target at a sputtering rate of about 0.6nm / min; then lower the temperature at 150°C / min The temperature is lowered to 20°C, and about 10 layers of hexagonal boron nitride films are obtained on graphene (Raman spectroscopy such as Figure 4 shown in curve b).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com