Method for making square aperture plane micro-lens array with high filling coefficient

A technology of microlens array and filling factor, which is applied in lens, optics, instruments, etc., can solve the problems of long ion exchange time and low ion mobility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0055] Such as Figure 11 As shown, the description of each step is as follows:

[0056] (a) is coating a titanium film on a glass substrate, (b) is uniformly coating photoresist, (c) is exposing (ultraviolet light), (d) is developing, (e) is removing titanium film from a window, (f) For photoresist removal, (g) for ion exchange.

[0057] The specific implementation process is as follows,

[0058] (1) Template preparation: design the size of the template, and then make the template;

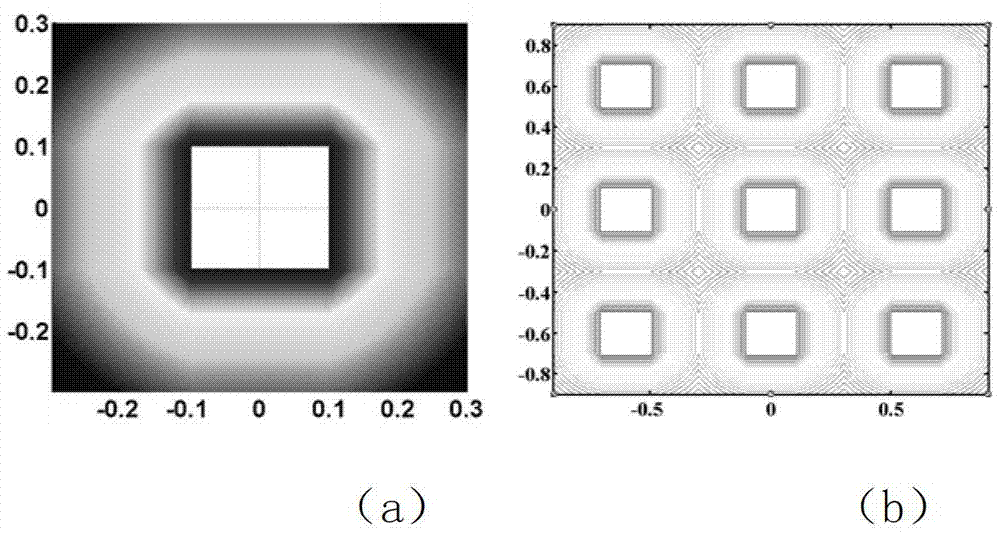

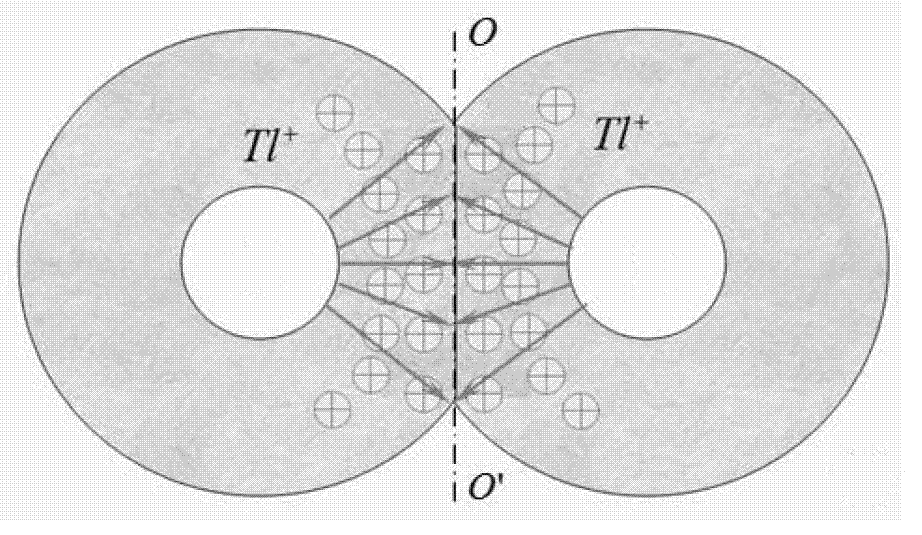

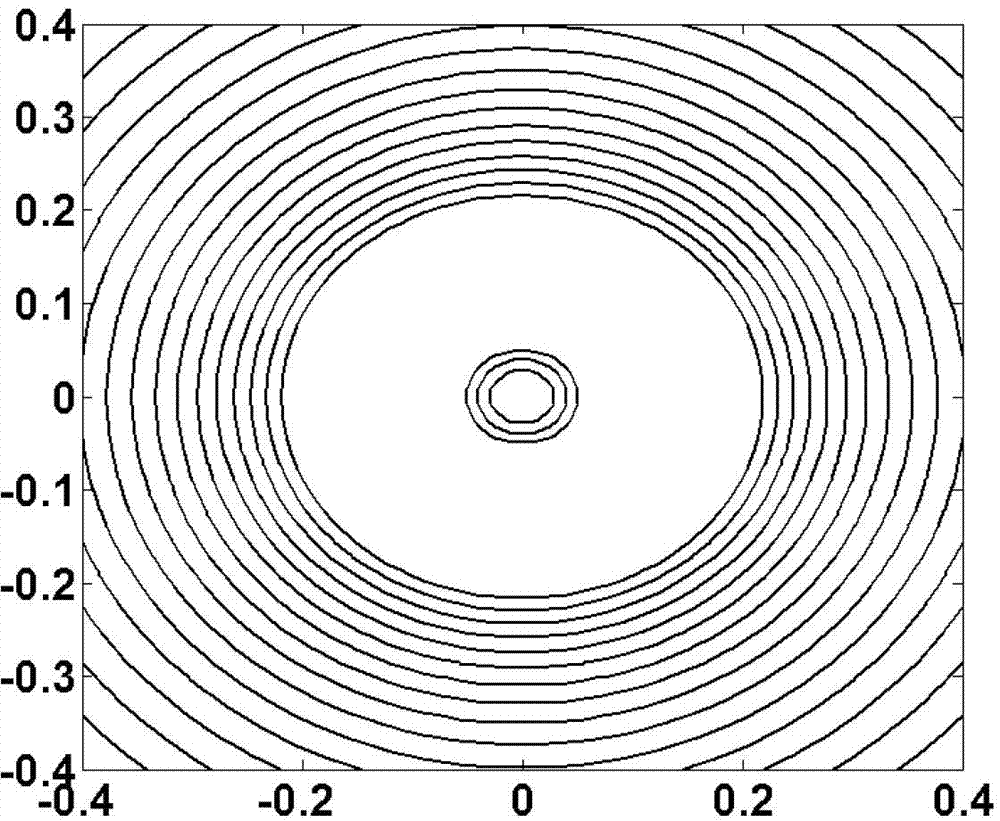

[0059] Experiments have proved that even if the ion exchange time of the circular window array is very long, there will always be unexchanged areas between the nearest neighbor windows, and it is difficult to achieve a high fill factor. Therefore, to make a planar microlens array with a high filling factor, square windows and their corresponding arrangements can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com