Method for preparing waterproof and antifogging surface modified glass

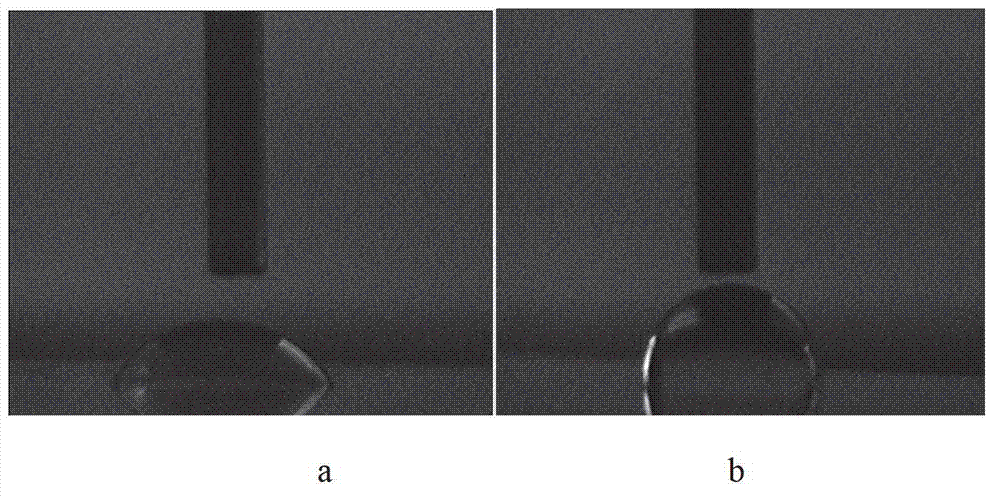

A surface modification and glass technology, which is applied in the field of waterproof and anti-fog glass, can solve the problems of poor adhesion, uniformity and performance stability of self-assembled molecular films, and achieve the effect of easy industrialization of products, improvement of hydrophobicity and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

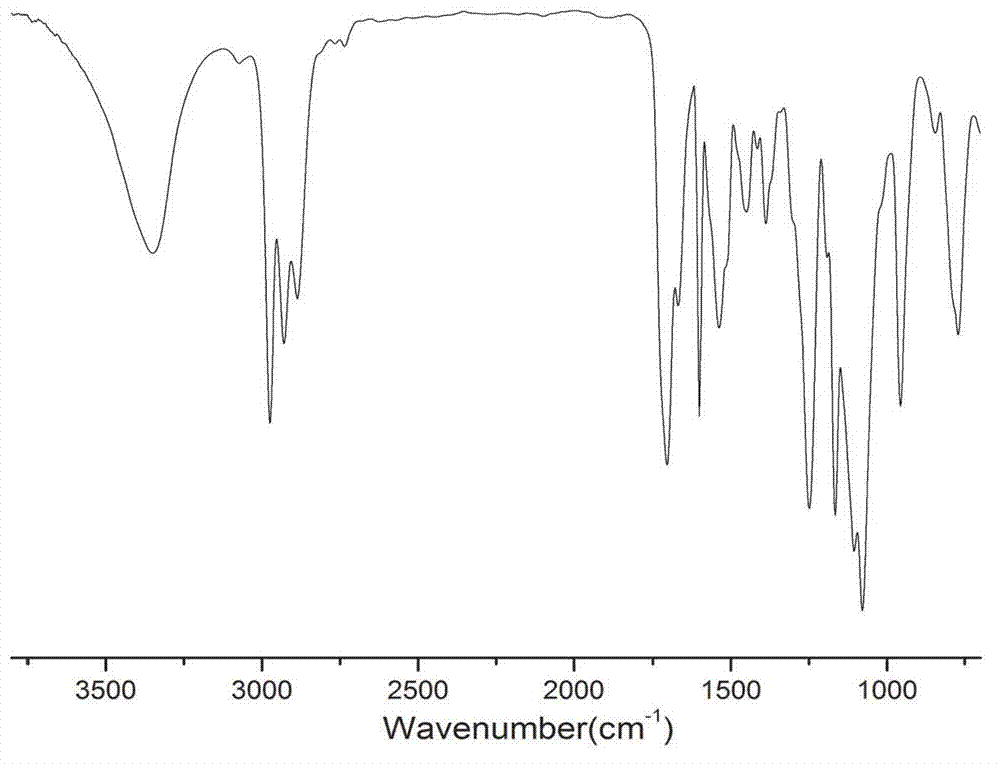

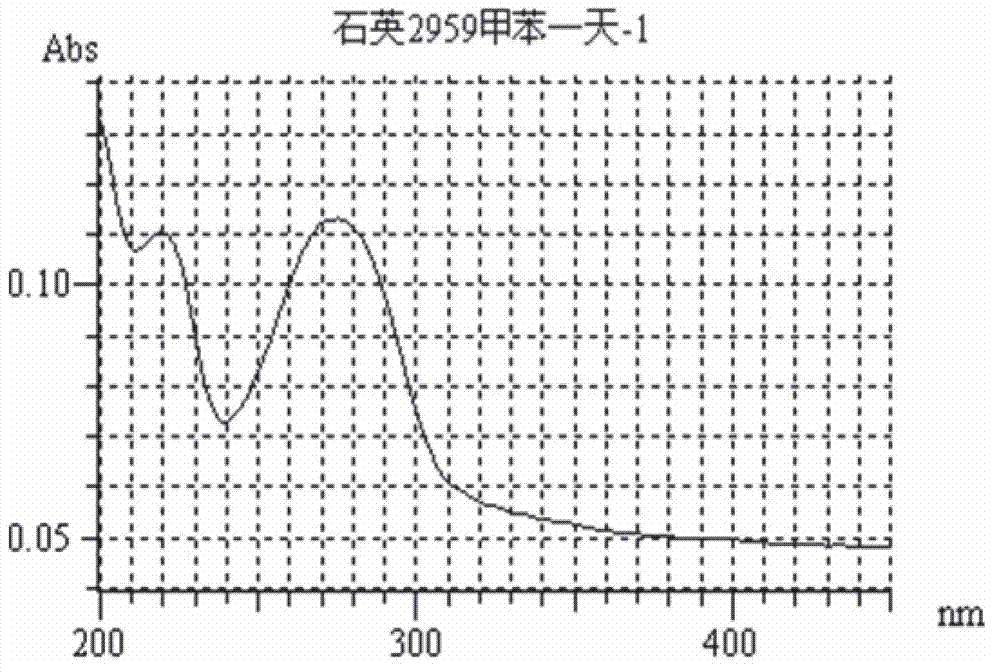

[0031] (1) Synthesis of silicon-containing photoinitiator: the molar ratio of isocyanate-containing silane coupling agent and 2-hydroxy-4-(2-hydroxyethoxy)-2-methylpropiophenone is 2:1 The reaction was carried out in dewatered ethyl acetate, using dibutyltin dilaurate DBTDL as a catalyst, the added amount of the catalyst was 0.05% of the mass fraction of the reactant, and the reaction was carried out for 4 hours to obtain a silicon-containing photoinitiator. The product is tested by infrared.

[0032] (2) Hydroxylation of the glass surface: use a glass slide, use deionized water, ethanol, and acetone respectively to sonicate for 10 minutes, then, 98% concentrated sulfuric acid by mass percentage: 30% hydrogen peroxide by volume ratio Soak the slides in the washing solution prepared at 7:3 for 10 hours to remove the insoluble organic matter on the surface of the slides, and at the same time form hydroxyl-rich slides.

[0033] (3) Chemically bond the silicon-containing photoinitiato...

Embodiment 2

[0038] (1) Synthesis of silicon-containing photoinitiator: the molar ratio of isocyanate-containing silane coupling agent and 2-hydroxy-4-(2-hydroxyethoxy)-2-methylpropiophenone is 3:1 It is reacted in dehydrated ethyl acetate, using dibutyl tin dilaurate DBTDL as a catalyst, and the catalyst is added in an amount of 0.1% of the mass fraction of the reactant. The reaction is carried out for 6 hours to obtain a silicon-containing photoinitiator. The product is tested by infrared.

[0039] (2) Hydroxylation of the glass surface: use a glass slide, ultrasonically use deionized water, ethanol, and acetone for 20 minutes, then, 98% concentrated sulfuric acid with a mass percentage concentration: 30% hydrogen peroxide by volume ratio The 7:3 washing solution soaks the slides for 17 hours to remove the insoluble organic matter on the surface of the slides and at the same time form hydroxyl-rich slides.

[0040] (3) Chemically bond the silicon-containing photoinitiator in step (1) to the ...

Embodiment 3

[0045] (1) Synthesis of silicon-containing photoinitiator: the molar ratio of isocyanate-containing silane coupling agent and 2-hydroxy-4-(2-hydroxyethoxy)-2-methylpropiophenone is 4:1 It is reacted in dehydrated ethyl acetate, using dibutyl tin dilaurate DBTDL as a catalyst, and the catalyst is added in an amount of 0.2% of the mass fraction of the reactant. The reaction is carried out for 8 hours to obtain a silicon-containing photoinitiator. The product is tested by infrared.

[0046] (2) Hydroxylation of the glass surface: use a glass slide, use deionized water, ethanol, and acetone respectively to sonicate for 30 minutes, then, 98% concentrated sulfuric acid with a mass percentage concentration of 98%: hydrogen peroxide with a mass percentage concentration of 30% according to the volume ratio The washing solution prepared at 7:3 soaks the slides for 24 hours to remove the insoluble organic matter on the surface of the slides, and at the same time form a hydroxylated glass sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com