Application of ZSM-5 molecular sieve loaded cobalt catalyst in preparation of cinnamyl alcohol

A technology of ZSM-5, 1. ZSM-5 is applied in the application field of preparing cinnamyl alcohol, and achieves the effects of strong selectivity, easy control of reaction conditions and improved conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

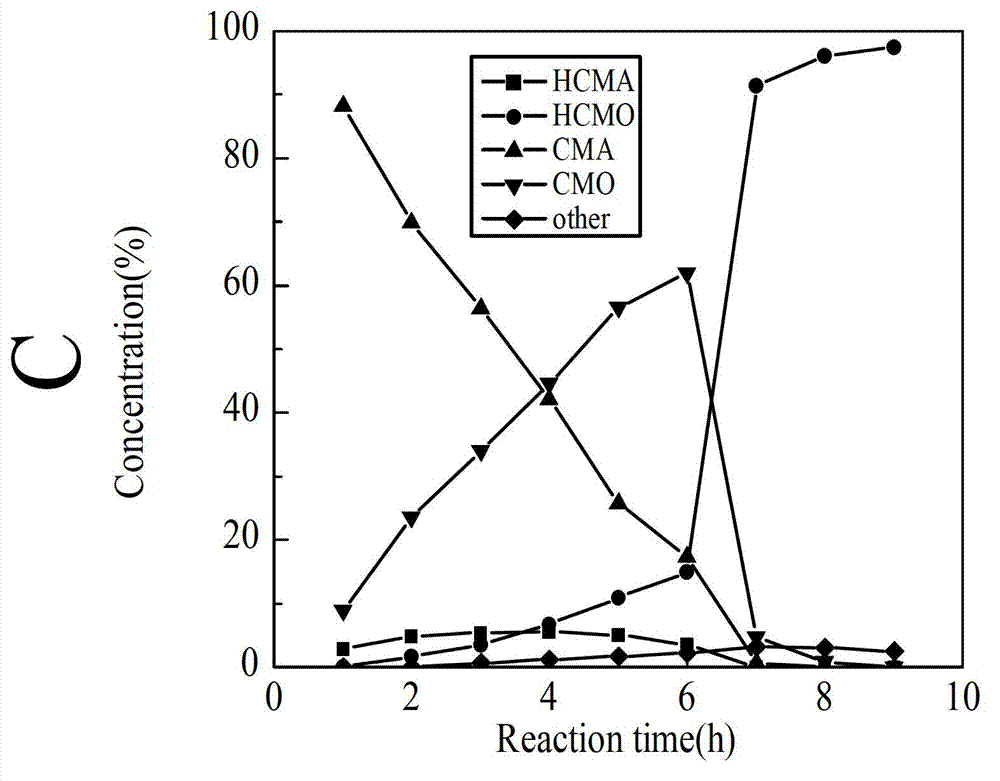

[0022] Using cinnamaldehyde 5ml as raw material, ZSM-5 molecular sieve loaded cobalt catalyst, hydrogenation conditions were carried out continuously for more than 6 hours, wherein the reaction pressure was 2Mpa, the reaction temperature was controlled at 100°C, and the reaction solvent was 130ml ethanol. Among them, the silicon in the catalyst The aluminum ratio is 25, and the mass content of the cobalt catalyst supported by the ZSM-5 molecular sieve is 16.7%. The calcination temperature of the cobalt catalyst supported by the ZSM-5 molecular sieve in this example is 600° C. during the preparation process. The result is as figure 1 shown.

[0023] From figure 1 It can be seen that the reactants and products change with time during the hydrogenation reaction of cinnamaldehyde. It can be seen from the figure that in the initial stage of the reaction, the content of cinnamyl alcohol rises rapidly, while the contents of hydrogenated cinnamaldehyde and hydrogenated cinnamyl alco...

Embodiment 2

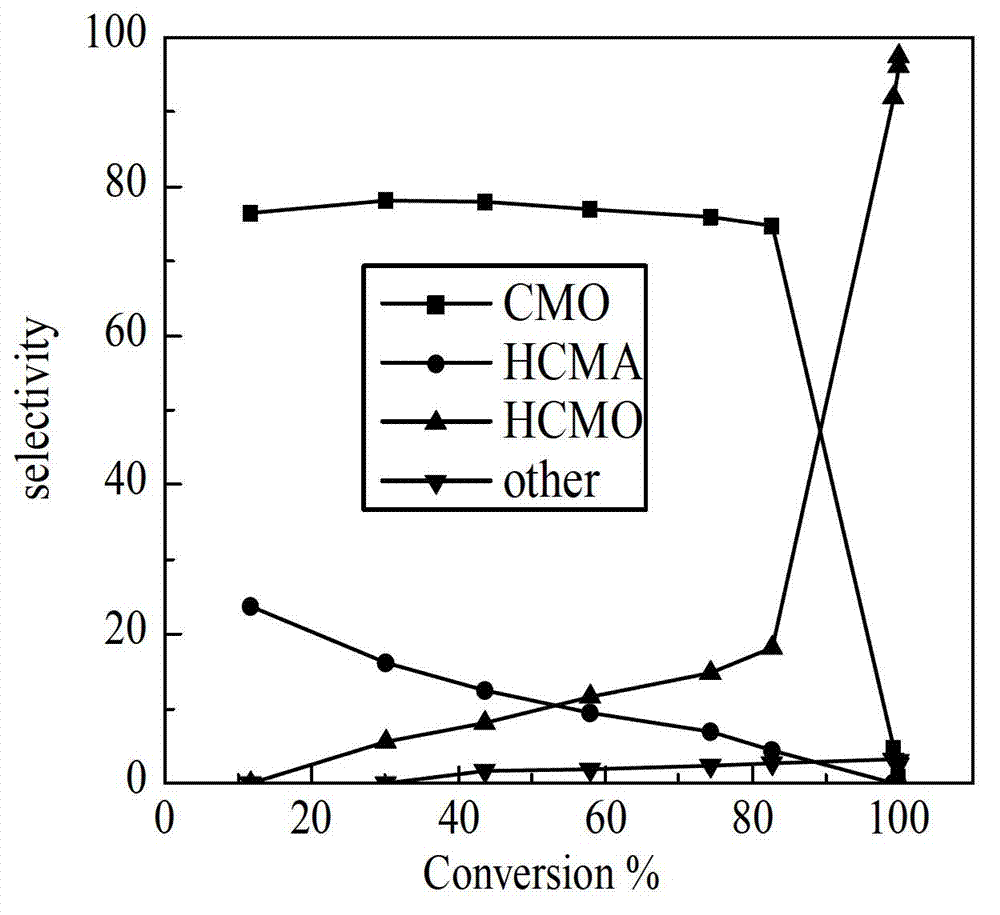

[0025] With the same reaction situation of embodiment 1, compare the relation between the selectivity of each product and conversion rate, obtain the result as follows figure 2 As can be seen from the figure, the content of hydrogenated cinnamaldehyde and acetal by-products is relatively low. When the conversion rate of cinnamaldehyde is less than 80%, the selectivity of cinnamyl alcohol is maintained at about 78%. After further reaction, the selectivity of cinnamyl alcohol decreases rapidly, and cinnamyl alcohol further generates hydrogenated cinnamyl alcohol.

Embodiment 3

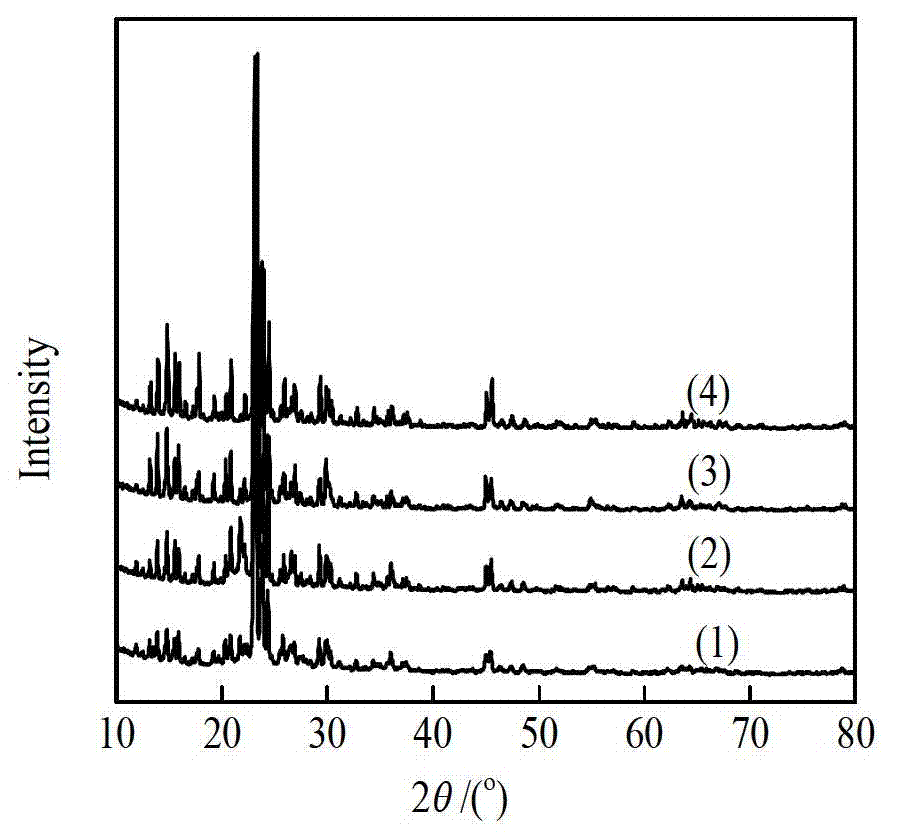

[0027] With different catalysts as contrast test, compare in the cinnamyl alcohol preparation process, use parameters such as the efficiency of different catalysts, reaction condition is identical with embodiment 1, concrete result is as follows:

[0028]

[0029] As can be seen from the above table, in the selective hydrogenation reaction of cinnamaldehyde, the carrier has a greater impact on the selectivity of hydrogenation performance and product. We prepared cobalt catalysts supported on alumina, zirconia, magnesia, oxidation states and ZSM-5 molecular sieves, and investigated their reactivity in the selective hydrogenation of cinnamaldehyde. The carrier has a great influence on the activity of the catalyst and the hydrogenation performance of the product. After 6 hours of reaction, the catalysts supported by alumina, magnesia and titania have a hydrogenation conversion of 4.7%, 1.4% and 3.6%, respectively, and their reactivity is very high. Low. The catalyst supported...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com