Preparation processes of porous hydrogel and nonporous hydrogel

A technology of porous hydrogel and preparation process, which is applied in the field of preparation technology of porous hydrogel and non-porous hydrogel, can solve the problems such as difficulties and difficulties in drug loading of hydrogel, and achieves reduction of production cost, simplification of production process, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

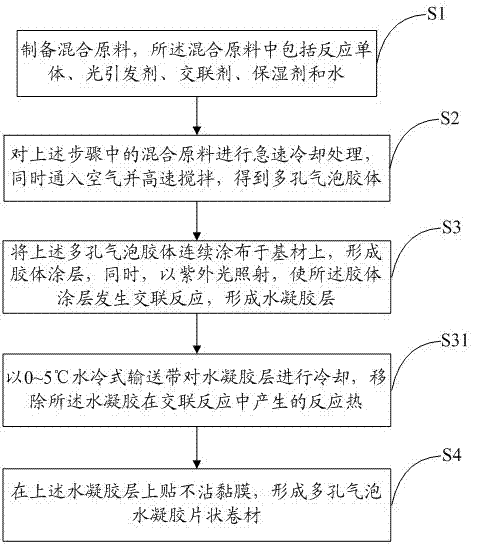

[0040] figure 1 It is a schematic flow chart of the preparation process of the porous hydrogel in Example 1 of the present invention.

[0041] refer to figure 1 As shown, the embodiment of the present invention provides a porous hydrogel preparation process, comprising the following steps:

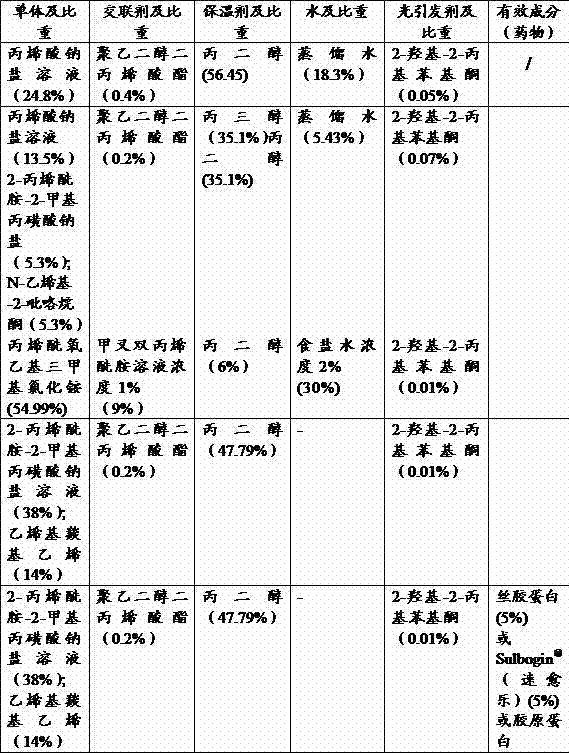

[0042] S1: preparing a mixed raw material, which includes a reactive monomer, a photoinitiator, a crosslinking agent, a moisturizing agent and water;

[0043] S2: performing rapid cooling on the mixed raw materials in the above steps, while introducing air and stirring at a high speed to obtain a porous colloid;

[0044] S3: Continuously coating the above-mentioned porous bubble colloid on the substrate to form a colloid coating, and at the same time, irradiating with ultraviolet light to cause a cross-linking reaction of the colloid coating to form a hydrogel layer;

[0045] S4: Paste a non-stick mucous membrane on the hydrogel layer to form a hydrogel sheet-like coil with porous bubbl...

Embodiment 2

[0058] Fig. 2 is a schematic flow chart of the preparation process of the non-porous hydrogel in Example 2 of the present invention.

[0059] Referring to Fig. 2, the embodiment of the present invention also provides a non-porous hydrogel preparation process, which differs from the porous hydrogel preparation process shown in Example 1 mainly in that during the rapid cooling process, no air, and the entire cooling process is completed in a vacuum container, the specific steps are as follows:

[0060] P1: Prepare mixed raw materials, which include reactive monomers, photoinitiators, crosslinking agents, moisturizing agents and water;

[0061] P2: Put the mixed raw materials in the above steps into a vacuum container, perform a rapid cooling treatment on the vacuum container, and stir at a high speed at the same time to obtain a non-porous colloid;

[0062] P3: Continuously coating the non-porous colloid in step P2 on the substrate to form a colloid coating, and at the same tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com