High-gloss ABS (acrylonitrile-butadiene-styrene) alloy and method for preparing same from matte ABS

An alloy, high-gloss technology, applied in the field of high-gloss ABS alloy and its preparation, can solve the problems of poor fluidity and poor colorability, and achieve the effects of reduced cost, excellent gloss and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

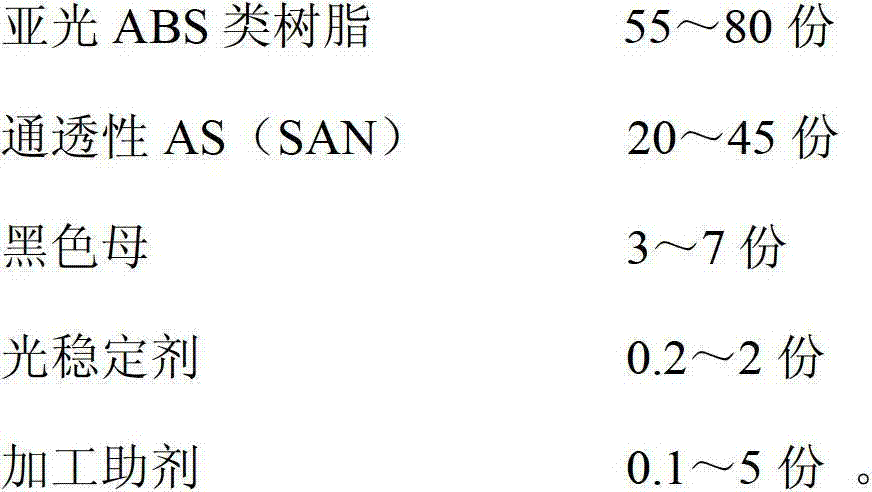

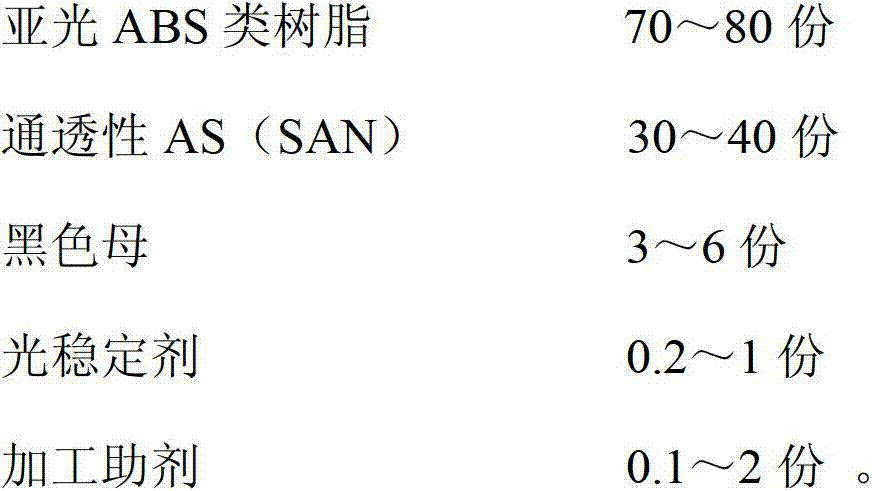

Method used

Image

Examples

Embodiment 1

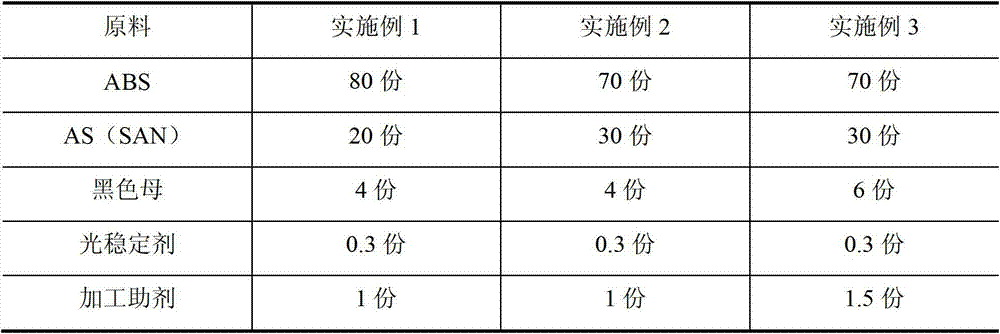

[0034] For the high-gloss ABS alloy, the weight composition of its raw materials is shown in Table 1.

[0035] The matt ABS resin is selected from acrylonitrile-styrene-butadiene graft copolymer (Shanghai Gaoqiao ABS275), with a melt flow rate of 8g / 10min (10Kg, 220°C) and high impact resistance (notched impact strength). is 270J / m);

[0036] The selected permeability AS is Taiwan Taihua NF2200, which has high hardness, high transparency and high melt flow rate, and the melt index is 35g / 10min;

[0037] The selected black masterbatch is ABS-based high-precision color masterbatch, such as bright pigment masterbatch 2016C;

[0038] The selected processing aid is a combination of lubricant, white mineral oil and brightener, wherein the weight ratio is 1 part of lubricant, 0.2 part of white mineral oil, and 0.5 part of brightener.

[0039] The selected light stabilizers are Irganox1010 and Irganox168 of Ciba Corporation.

[0040] Dry the matt ABS resin, AS (SAN), black masterbatc...

Embodiment 2

[0044] For the high-gloss ABS alloy, the weight composition of its raw materials is shown in Table 1, and the preparation method is the same as that in Example 1.

Embodiment 3

[0046] For the high-gloss ABS alloy, the weight composition of its raw materials is shown in Table 1, and the preparation method is the same as that in Example 1.

[0047] Table 1 embodiment proportioning

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com