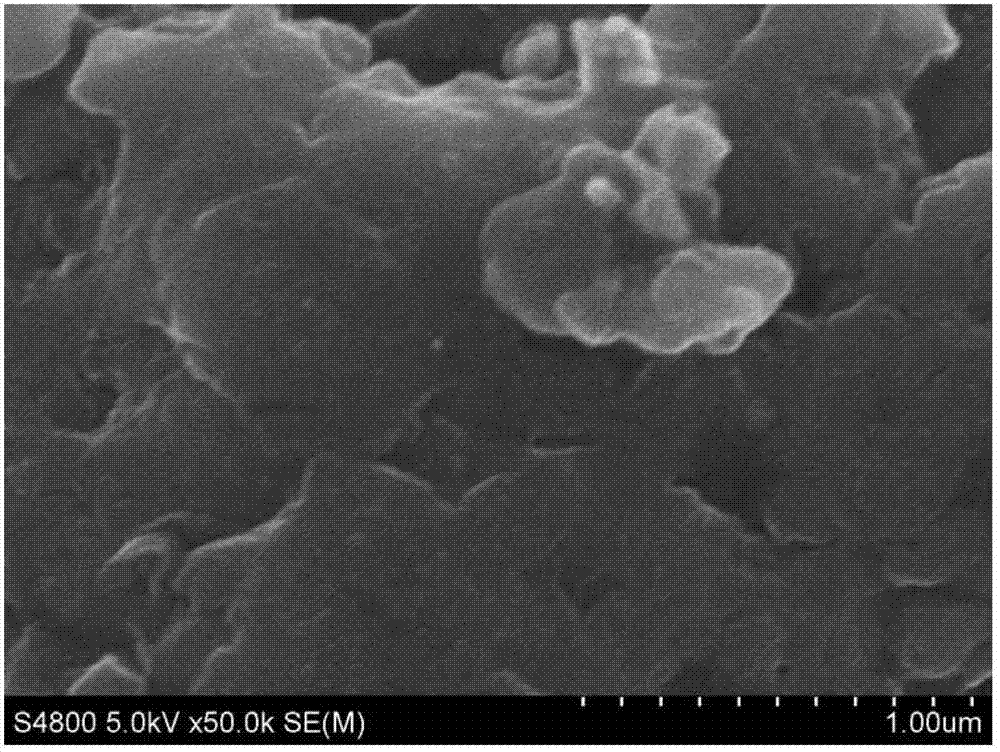

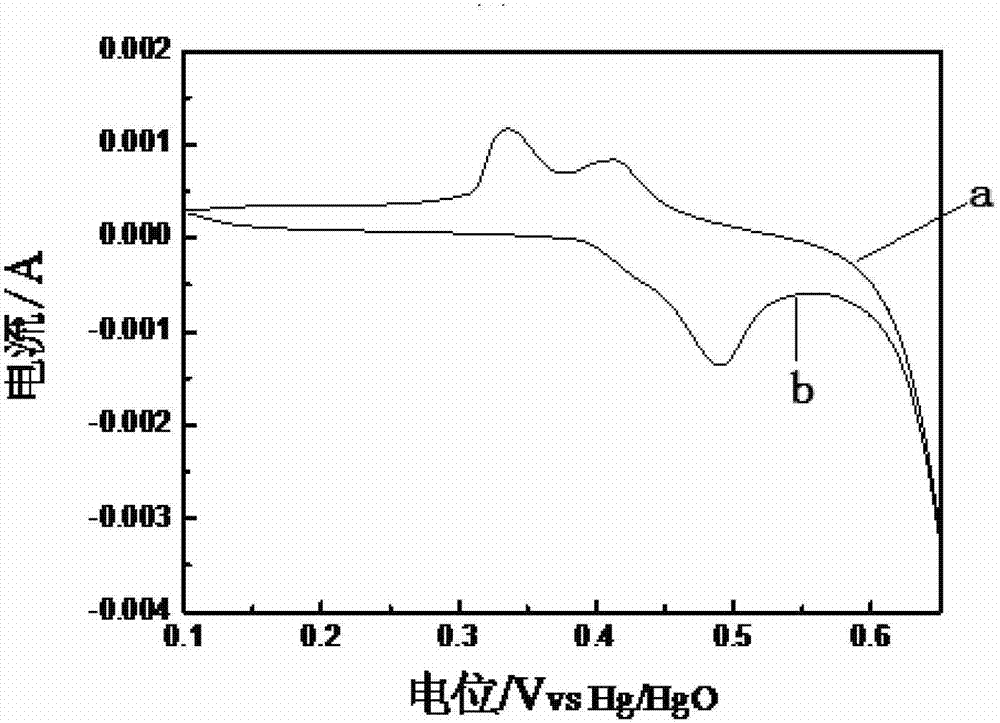

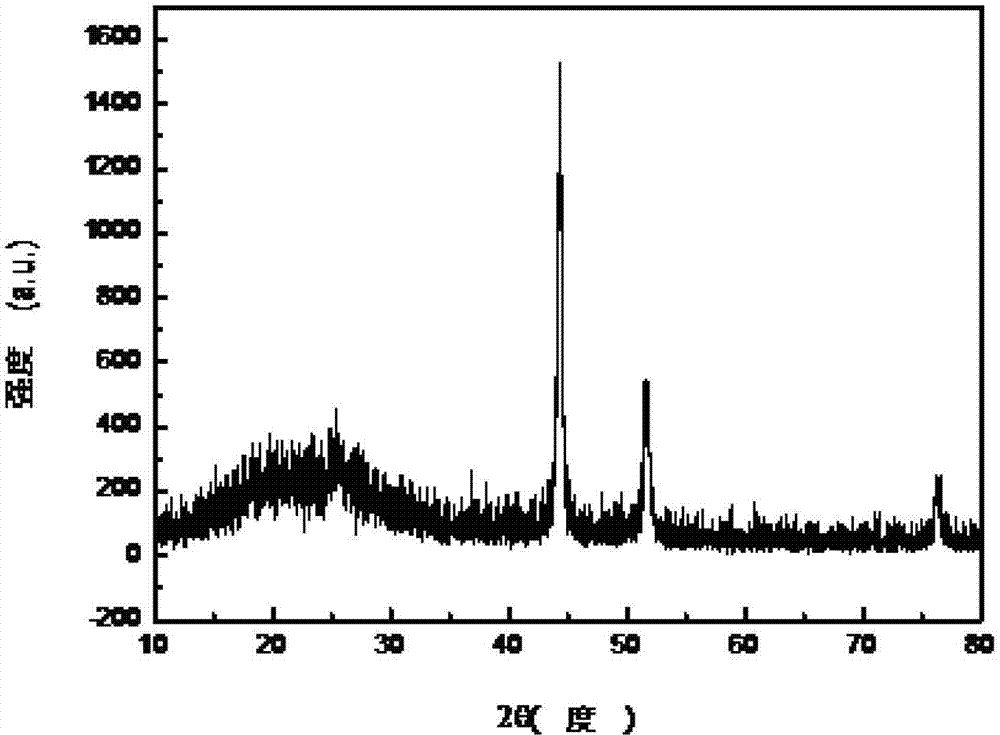

Preparation method of polyaniline/graphene/nano nickel composite material

A composite material and graphene technology is applied in the field of preparation of polyaniline composite materials, which can solve the problem that polyaniline does not have electrical properties, and achieve the effects of improving electrochemical properties, uniform size and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment one: the preparation method of polyaniline / graphene / nano-nickel composite material of the present embodiment is realized according to the following steps:

[0015] 1. Preparation of graphene oxide solution: Add 1.0-1.5 g of flake graphite to 40-60 ml of sulfuric acid with a mass percentage of 98%, stir in an ice-water bath at 0-4°C for 20-40 minutes, then add 1-2 g of nitric acid Sodium and 9~11g potassium permanganate, react for 1~3h; then place in a 35°C water bath for 9~13h, then add 350~450mL distilled water to dilute, carry out ultrasonic dispersion, then add 80~100mL with a mass percentage of 5% H 2 o 2 , then add 45-55mL dilute hydrochloric acid; then carry out suction filtration and centrifugation to collect the solid phase, then dissolve it in 350-450ml distilled water, then put it into a semi-permeable membrane for dialysis treatment until the solution is neutral, and then dilute it with distilled water To a concentration of 0.001-0.003g / ...

specific Embodiment approach 2

[0019] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, it is placed in a water bath at 35° C. for 10 h. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in step 1, dissolve in 400 mL of distilled water. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com