Praseodymium and ytterbium codope gadolinium oxide up-conversion luminescent material and preparation method and application thereof

A technology of luminescent materials and co-doping, which is applied in the fields of luminescent materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the above-mentioned terbium-ytterbium co-doped gadolinium oxide up-conversion luminescent material comprises the following steps:

[0024] Step S11, according to Gd 2 o 3 :xTb 3+ ,yYb 3+ The stoichiometric ratio of each element is weighed as Gd 2 o 3 , Tb 2 o 3 and Yb 2 o 3 Powder, where 0.01≤x≤0.05, 0.01≤y≤0.1.

[0025] In this step, preferably, x is 0.06 and y is 0.1.

[0026] It can be understood that Gd can also be weighed in this step 2 o 3 , Tb 2 o 3 and Yb 2 o 3 Powder and mix evenly, where Gd 2 o 3 , Tb 2 o 3 and Yb 2 o 3 The mass ratio is 3.082~3.553:0.036~0.183:0.039~0.394, preferably 3.336:0.109:0.197.

[0027] Step S13, mixing the powder weighed in step S11 evenly to obtain a precursor.

[0028] In this step, the powder is ground in a corundum bowl for 20 minutes to 60 minutes to obtain a homogeneously mixed precursor, preferably for 40 minutes.

[0029] Step S15, burning the precursor at 800°C-1000°C for 0.5...

Embodiment 1

[0038] Choose powder with a purity of 99.99%, Gd 2 o 3 , Tb 2 o 3 and Yb 2 o 3 Powder, its mass ratio is 3.336:0.109:0.197. Grind in a corundum mortar for 40 minutes to mix well, then fire at 950 °C for 3 hours. Then cool to 250°C and keep warm for 2 hours, then naturally cool to room temperature to take out the block product, and pulverize it to obtain the general chemical formula of Gd 2 o 3 :0.03Tb 3+ , 0.05Yb 3+ up-converting phosphors.

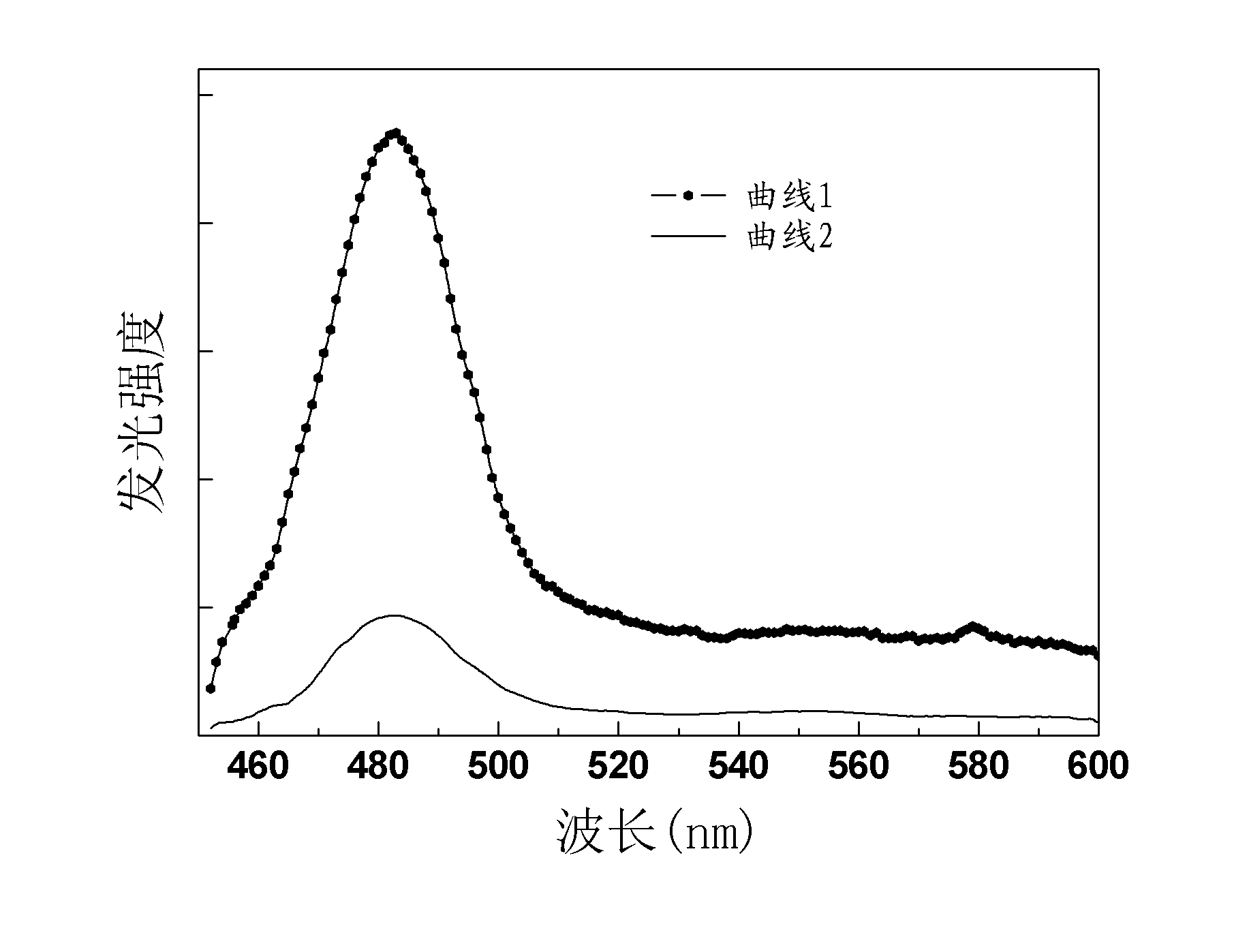

[0039] see figure 2 , figure 2 Shown are the obtained terbium-ytterbium co-doped gadolinium oxide up-conversion luminescent material and samples without ytterbium (chemical formula is Gd 2 o 3 :0.03Tb 3+ ) photoluminescence spectrum. Depend on figure 2 It can be seen that the excitation wavelength of the terbium-ytterbium co-doped gadolinium oxide up-conversion luminescent material obtained in this embodiment is 980nm, and in the 485nm wavelength region, Tb 3+ ion 5 D. 4 → 7 h 6 The transition radiation of the terb...

Embodiment 2

[0042] Choose powder with a purity of 99.99%, Gd 2 o 3 , Tb 2 o 3 and Yb 2 o 3 Powder, its mass ratio is 3.553:0.036:0.039. Grind in a corundum mortar for 20 minutes to mix well, then fire at 800°C for 5 hours. Then cool to 100°C and keep warm for 3 hours, then naturally cool to room temperature to take out the block product, and pulverize it to obtain the general chemical formula of Gd 2 o 3 :0.01Tb 3+ , 0.01Yb 3+ up-converting phosphor

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com