Reverse engineering processing system and method based on space code projection

A spatial encoding and reverse engineering technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems that affect product quality, have no research and development cases, and it is difficult to guarantee the smoothness of automatically reconstructed surfaces. Effects of stickiness and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

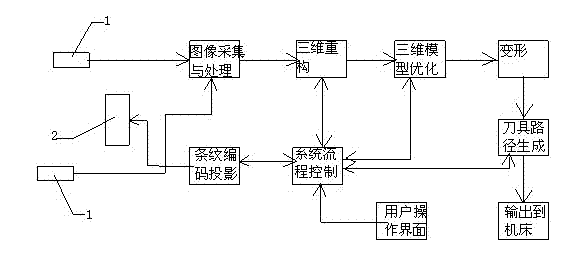

[0024] see figure 1 , a reverse engineering processing method based on spatial code projection, the method includes the following steps, 1) projecting a spatial code to an object to be collected, and then obtaining the coordinate information of the spatial scale of the object to be measured by means of video, 2) performing the collected 3) Analyze and calculate the generated surface model to generate the tool path.

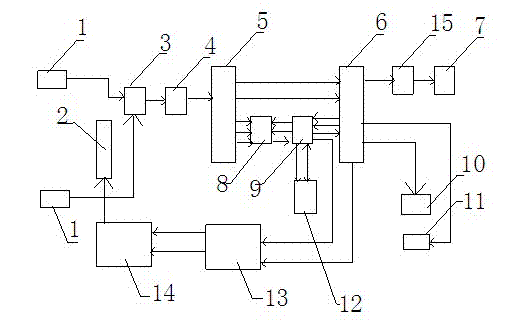

[0025]In step 1, the mathematical model of the projection system, in the structured light projection system, based on the principle of reversible optical path, the ideal projector 2 can be regarded as a reverse ideal pinhole camera, and the projection matrix P of the projector 2 can be decomposed into 3 × 3 The internal parameter matrix Ap of , the rotation matrix Rp of 3 × 3, the translation vector Tp between the coordinate systems of 3 × 1. Based on the pinhole model of the camera 1, the mathematical model of the ideal projector is established; based on the cod...

Embodiment 2

[0037] Example 2: As an improvement of the present invention, the three-dimensional reconstruction of the processed image mainly includes surface reconstruction and surface smoothing.

[0038] Triangulation is surface reconstruction. In reverse engineering, surface reconstruction undertakes the acquisition and processing of 3D point cloud data. At the same time, it is the basis for subsequent surface space filtering and smoothing. In reverse engineering, surface reconstruction is defined as follows: For Given a set of measurement data points, reconstruct a surface so that it can well approximate the actual model surface. According to the implementation strategy of surface reconstruction, the current surface reconstruction methods can be divided into two categories: one is to use the measured data points to fit the curve for surface modeling, and the other is to use the measured data points to directly perform surface fitting, namely It is to directly find the topological rel...

Embodiment 3

[0046] As an improvement of the present invention, in step 3, the processed model is calculated and analyzed to generate a tool path. The present invention selects the most widely used equal-section tool path generation algorithm. The method includes the calculation of section distance, the calculation of tool position point, the generation of tool position path and the generation of numerical control code. The section spacing calculation can be calculated by referring to the formula of tool line spacing in free-form surface machining, but for complex mesh surfaces, there are problems such as large curvature at details, which is difficult to calculate with formulas, so it is mainly considered comprehensively with time. As for the calculation of the tool position point, a method for calculating the tool position point is to calculate according to the tool contact point and the local features of the curved surface. Because the triangular mesh surface is difficult to describe wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com