Dust removal, desulfurization and denitrification device of coal-fired power generation boiler

A technology for desulfurization and denitrification and power generation boilers, which is applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high equipment investment and operation costs, achieve low construction and operation costs, and solve environmental problems in raw material production. The effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

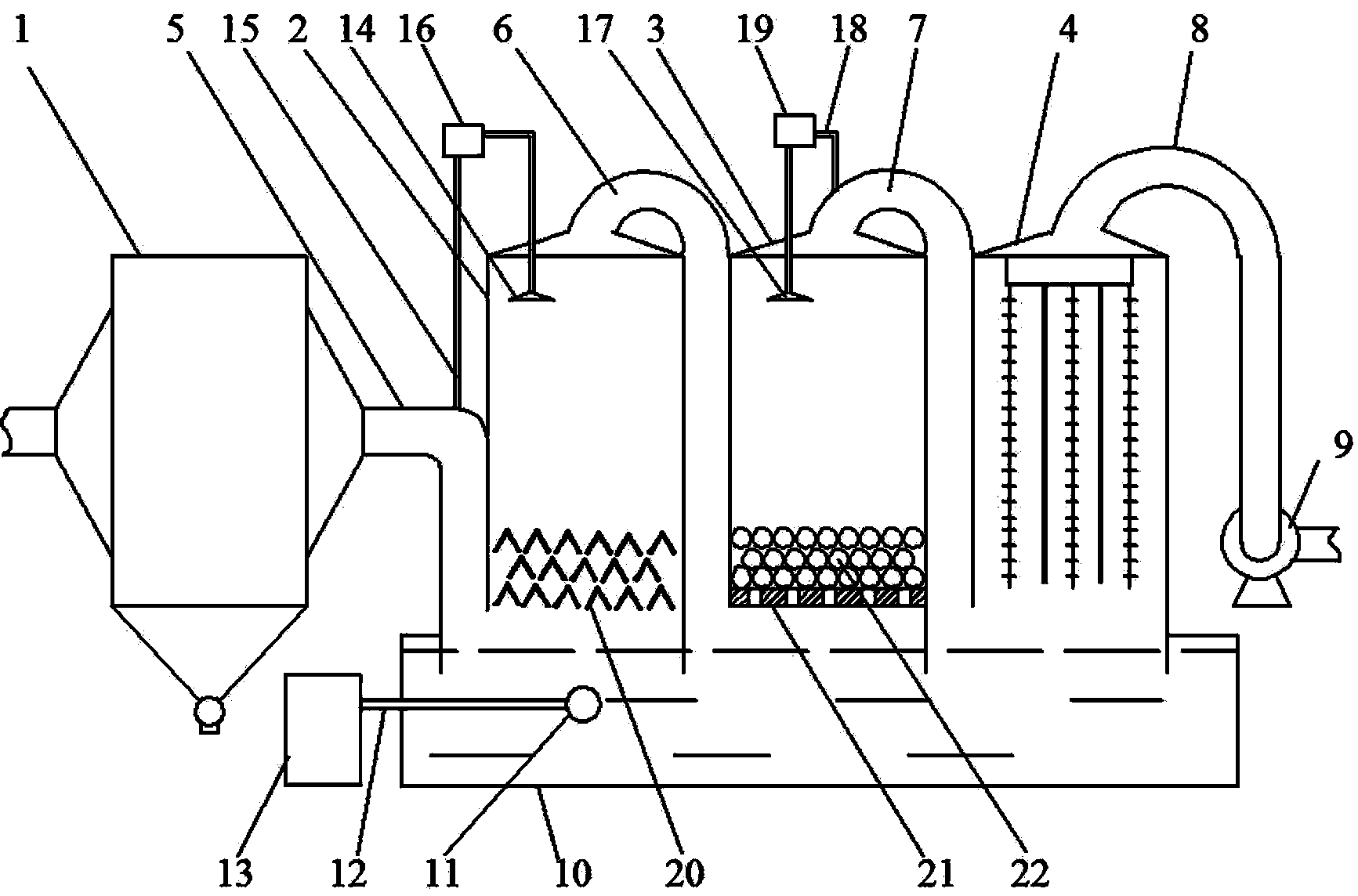

[0012] As shown in the attached figure, the dust removal, desulfurization and denitrification device of the coal-fired power generation boiler has an electrostatic precipitator 1, a dust removal, desulfurization and denitration primary spray room 2, a dust removal, desulfurization and denitrification secondary spray room 3 and a built-in corona wire. And the electrostatic defogging chamber 4 of the dust collecting plate. Wherein the electrostatic precipitator 1 can adopt the coal-fired power generation boiler electrostatic precipitator disclosed in CN2894856Y. The cooperation of the plates forms an efficient electrostatic precipitator, and its dust removal efficiency is as high as 90%. The charged water mist particles are collected by the dust collecting plate under the action of electrostatic attraction, and fall in the form of water droplets to achieve th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com