Getter

A technology of getter and sintering aid, which is applied in other chemical processes, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of powder drop, sharp drop of inhalation rate, and high activation temperature of getter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention has no special limitation on the preparation method of the getter, preferably prepared according to the following method:

[0043] Provide ternary alloy particles;

[0044] The ternary alloy particles, the second getter particles and the sintering aid are mixed and pressed to form a green body, and the material of the second getter particles is a metal element or a metal compound of the fourth subgroup;

[0045] The green body is sintered to obtain the getter.

[0046] The present invention provides ternary alloy particles. The present invention has no special restrictions on the preparation method of the ternary alloy particles, and the ternary alloy particles are preferably prepared by the method described in the above technical solution;

[0047] After the ternary alloy particles are obtained, the present invention mixes the ternary alloy particles with the second getter particles and sintering aid described in the above technical solution to o...

Embodiment 1

[0055] Use vacuum electric arc furnace to smelt Zr-V-Mn alloy, wherein the mass fraction of Zr is 80%, the mass fraction of V is 10%, the mass fraction of Mn is 10%, the Zr-V-Mn that will obtain under argon protection The alloy is crushed until the particle diameter is 50 μm ~ 100 μm, and the obtained Zr-V-Mn alloy particles with a particle size of 50 μm ~ 100 μm, Ti powder with a particle size of 50 μm ~ 100 μm and Mo powder with a particle size of 50 μm ~ 100 μm According to the mass ratio of 4.5:4.5:1, the mixture was mixed for 4 hours, and the obtained mixture was pressed and molded, and then put into a vacuum sintering furnace for sintering. The sintering temperature was 670° C. and the sintering time was 10 minutes to obtain the getter.

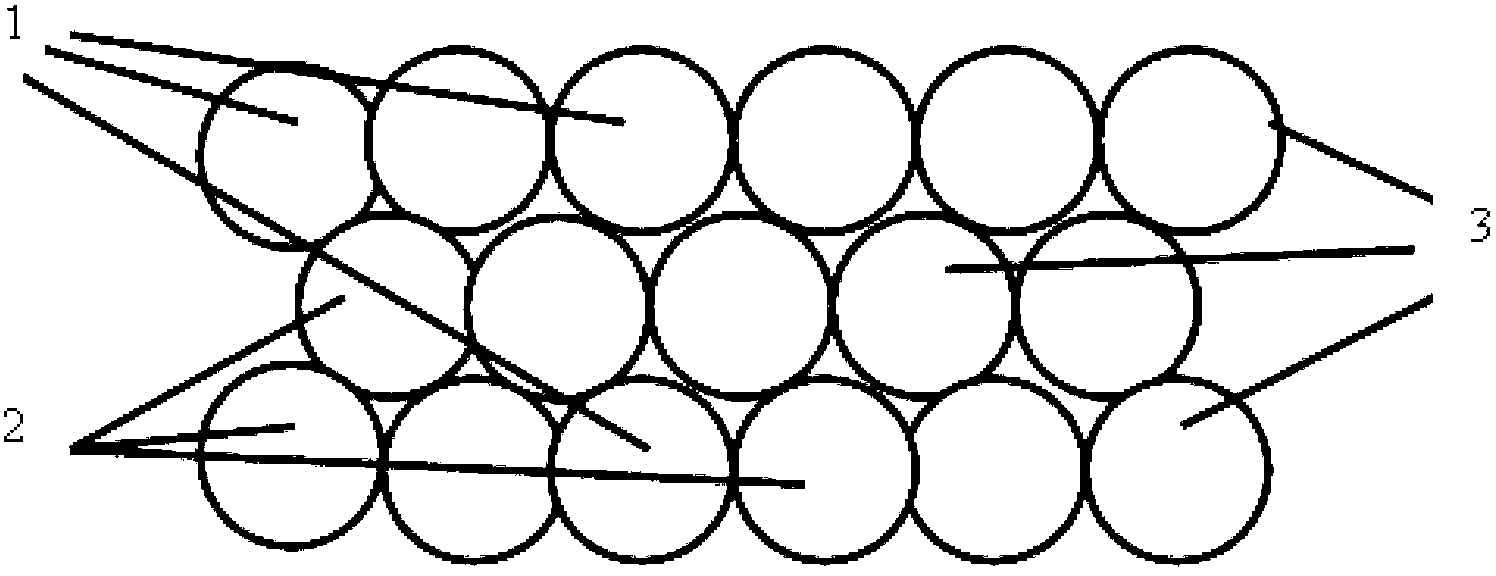

[0056] The structure of the getter obtained by the detection of the present invention shows that the getter obtained in this embodiment presents a porous structure;

Embodiment 2

[0059] Use vacuum electric arc furnace to smelt Zr-V-Mn alloy, wherein the mass fraction of Zr is 60%, the mass fraction of V is 35%, the mass fraction of Mn is 5%, the Zr-V-Mn that will obtain under argon protection The alloy is crushed until the particle diameter is 50 μm to 100 μm, and the obtained Zr-V-Mn alloy particles are mixed with Ti powder with a particle size of 50 μm to 80 μm and sintering aid Nb powder with a particle size of 50 μm to 80 μm in a mass ratio of 4:5 : 1 ratio batching, mixing for 5 hours, the obtained mixture was pressed into shape, then put into a vacuum sintering furnace for sintering, the sintering temperature was 770°C, and the sintering time was 15min to obtain the getter.

[0060] The structure of the getter obtained by the detection of the present invention shows that the getter obtained in this embodiment presents a porous structure;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com