Nickel-based catalyst and preparation method thereof

A nickel-based catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as poor nickel dispersion and achieve good technical effects. highly active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] At a constant temperature of 35°C, mix 12.9 grams of tetraethyl orthosilicate 6 grams, surfactant P123, 11.8 grams of concentrated hydrochloric acid, 0.18 grams of nickel nitrate, 6 grams of n-butanol, and 217 grams of water, and mix the mixed solution at a constant temperature of 35°C Stir under low temperature for 24 hours, then stand at 95°C for 48 hours, then cool it to room temperature and adjust pH=8 with ammonia water, continue to stand at 95°C for 48 hours, filter, dry, and place in a muffle furnace at 550°C Calcined under air atmosphere for 4 hours, then put it under hydrogen atmosphere, after 650°C reduction activation for 4 hours, the catalyst of the present invention was obtained.

[0018] Catalyst performance evaluation was carried out in a fixed-bed quartz reactor with an inner diameter of 7 mm, loaded with 0.2 g of catalyst, and fed methane and carbon dioxide gas with a molecular ratio of 1:1, and the space velocity was 1.56×10 4 Hour -1 , reacted at 800...

Embodiment 2~6

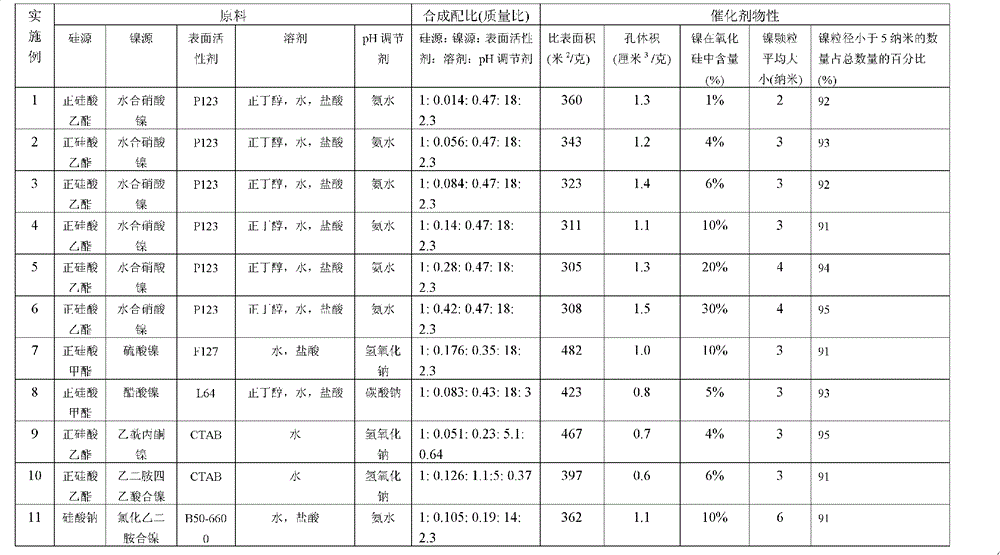

[0020] According to the synthesis steps described in Example 1, only changing the amount of nickel nitrate added, the catalyst of the present invention with a nickel content of 4%, 6%, 10%, 20%, and 30% can be synthesized. See catalyst formulation, preparation conditions and physical properties. Table 1 and Table 2. The catalyst evaluation method is the same as that in Example 1, and the catalytic reaction evaluation results are shown in Table 3.

Embodiment 7~18

[0022] According to the synthesis steps described in Example 1, the catalyst of the present invention can be synthesized by changing the type and proportion of silicon source, nickel source, surfactant, and pH regulator. The catalyst formula, preparation conditions and physical properties are shown in Table 1 and Table 2. . The catalyst evaluation method is the same as that in Example 1, and the catalytic reaction evaluation results are shown in Table 3.

[0023] Synthetic raw materials, proportioning ratio and catalyst physical properties of catalyst in Table 1 embodiment 1~18

[0024]

[0025]

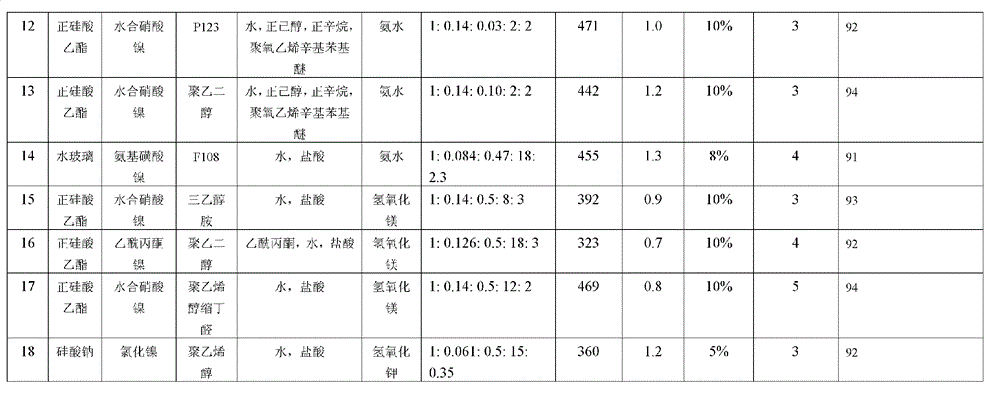

[0026] The preparation conditions of catalyst in table 2 embodiment 1~18

[0027]

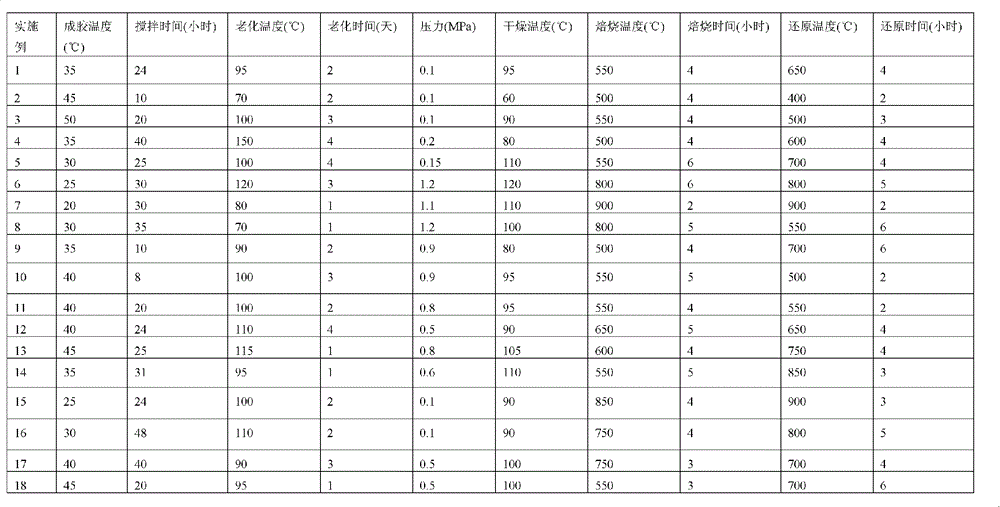

[0028] Catalytic performance of the catalyst in the embodiment 1-18 of table 3 to carbon dioxide reforming methane reaction

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com