Production method for sealing gasket

A technology for sealing gaskets and manufacturing methods, applied in chemical instruments and methods, lamination, layered products, etc. Cumbersome and other problems, to achieve the effect of good flexibility, not easy to age, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

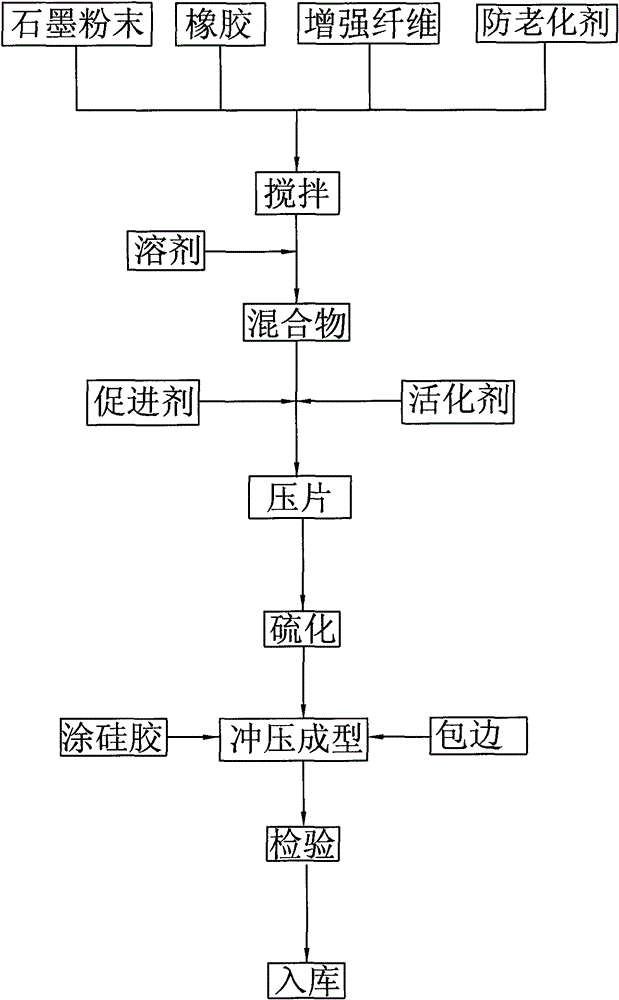

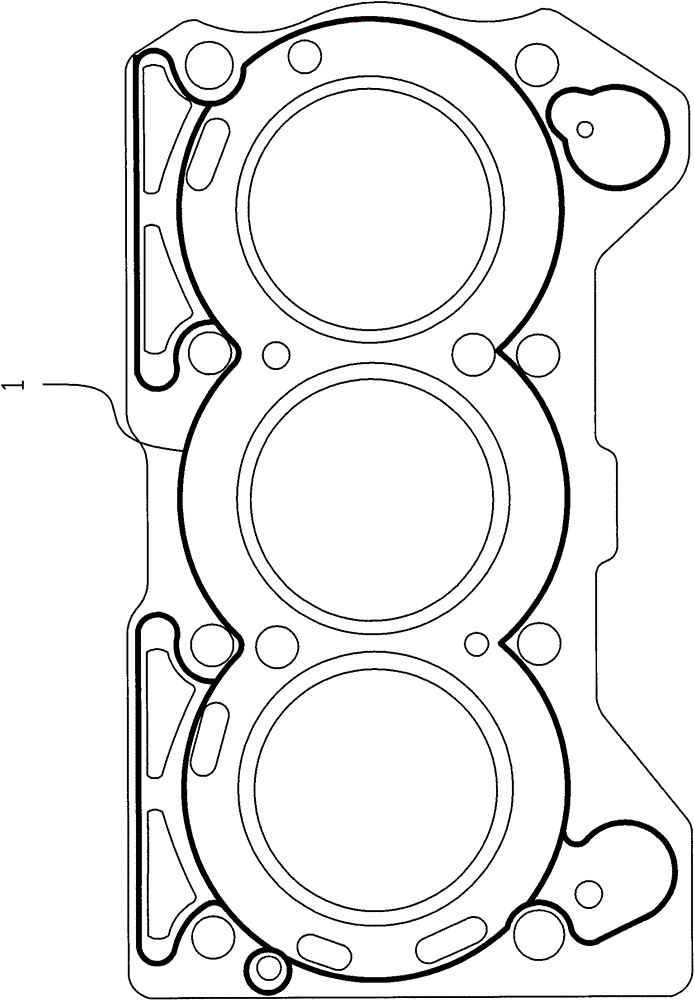

[0022] Such as figure 1 and figure 2 Shown, the formula of the embodiment of the present invention 1 comprises:

[0023] Formula A: 58 parts of graphite powder, 8 parts of natural rubber, 8 parts of aramid fiber, 0.8 part of sulfur, 0.8 part of accelerator, and 0.8 part of antiaging agent, the above are parts by weight.

[0024] Formula B: 60 parts of graphite powder, 10 parts of natural rubber, 10 parts of aramid fiber, 1 part of sulfur, 1 part of accelerator, 1 part of anti-aging agent, the above are parts by weight.

[0025] Formula C: 62 parts of graphite powder, 12 parts of natural rubber, 12 parts of aramid fiber, 1.2 parts of sulfur, 1.2 parts of accelerator, 1.2 parts of anti-aging agent, the above are parts by weight.

[0026] The accelerator in the above formula is 2-mercaptobenzothiazole or dithiodibenzothiazole, the anti-aging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com