Flexible impact-resistant composite automobile body and production process thereof

A composite material and manufacturing process technology, applied in vehicle parts, superstructure, transportation and packaging, etc., can solve the problems of not being able to adapt to safety and light weight, poor impact resistance, complex shape, etc., to avoid brittleness and fatigue characteristics , Improve the mechanical strength and impact resistance, the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

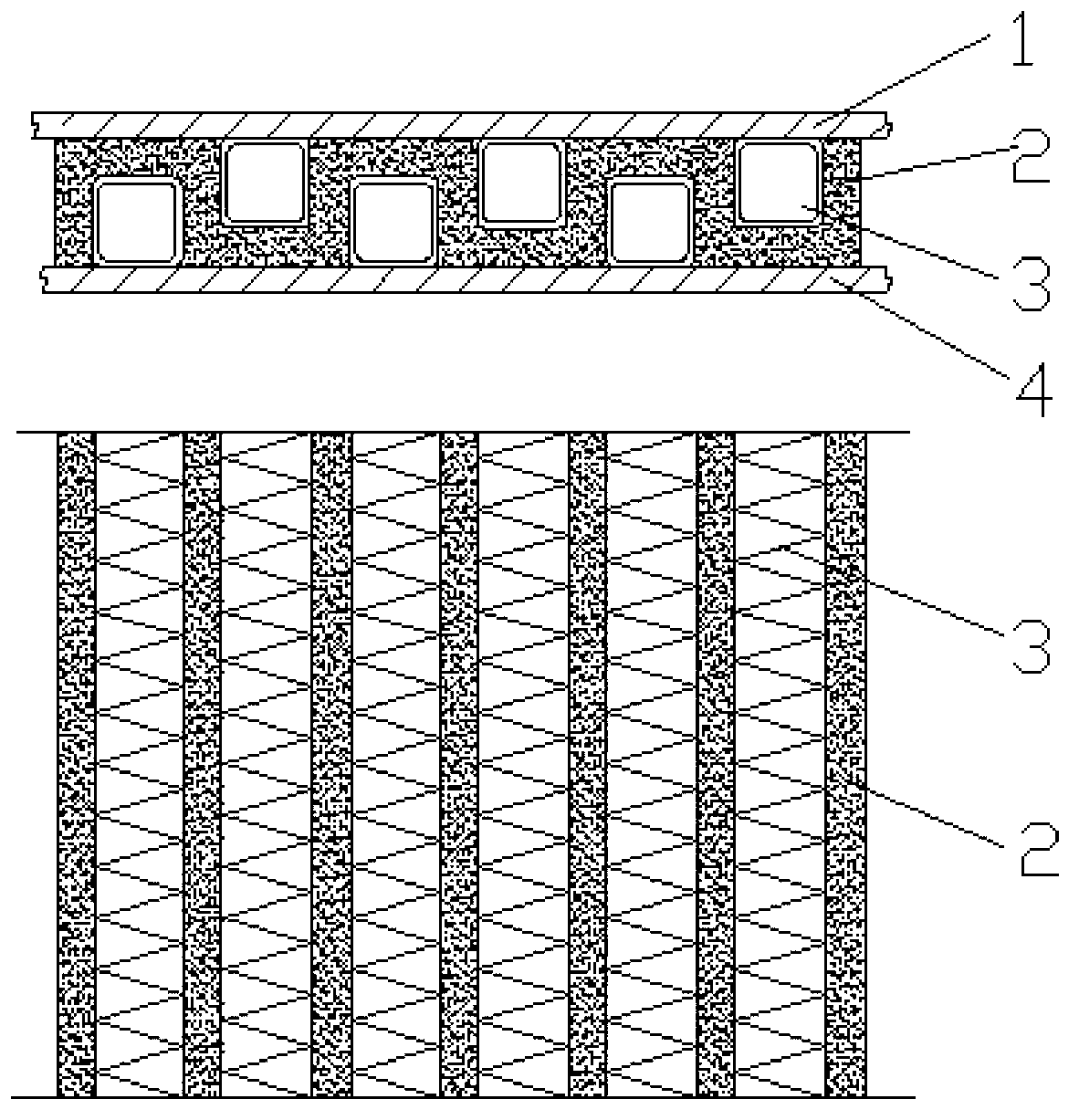

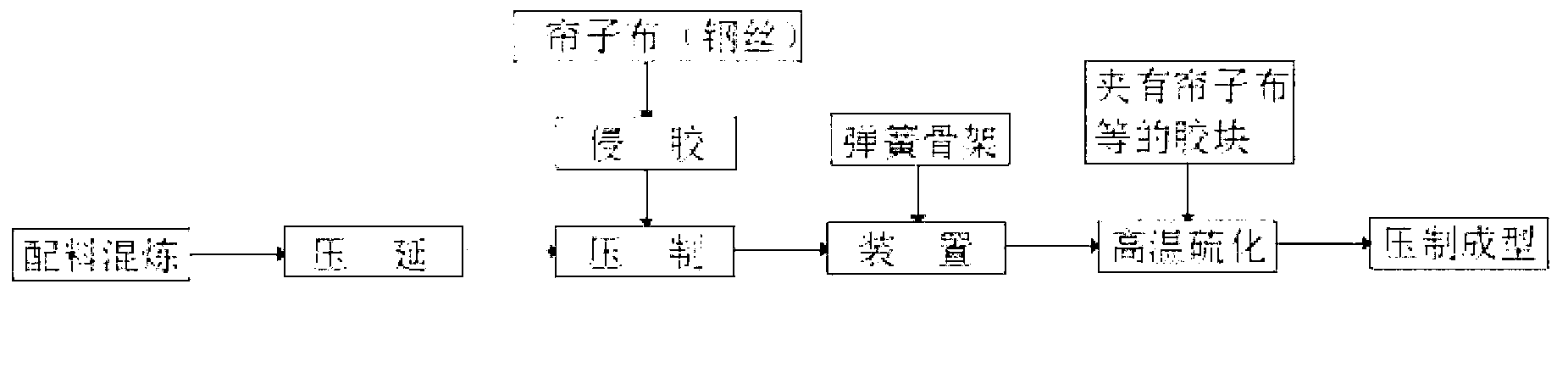

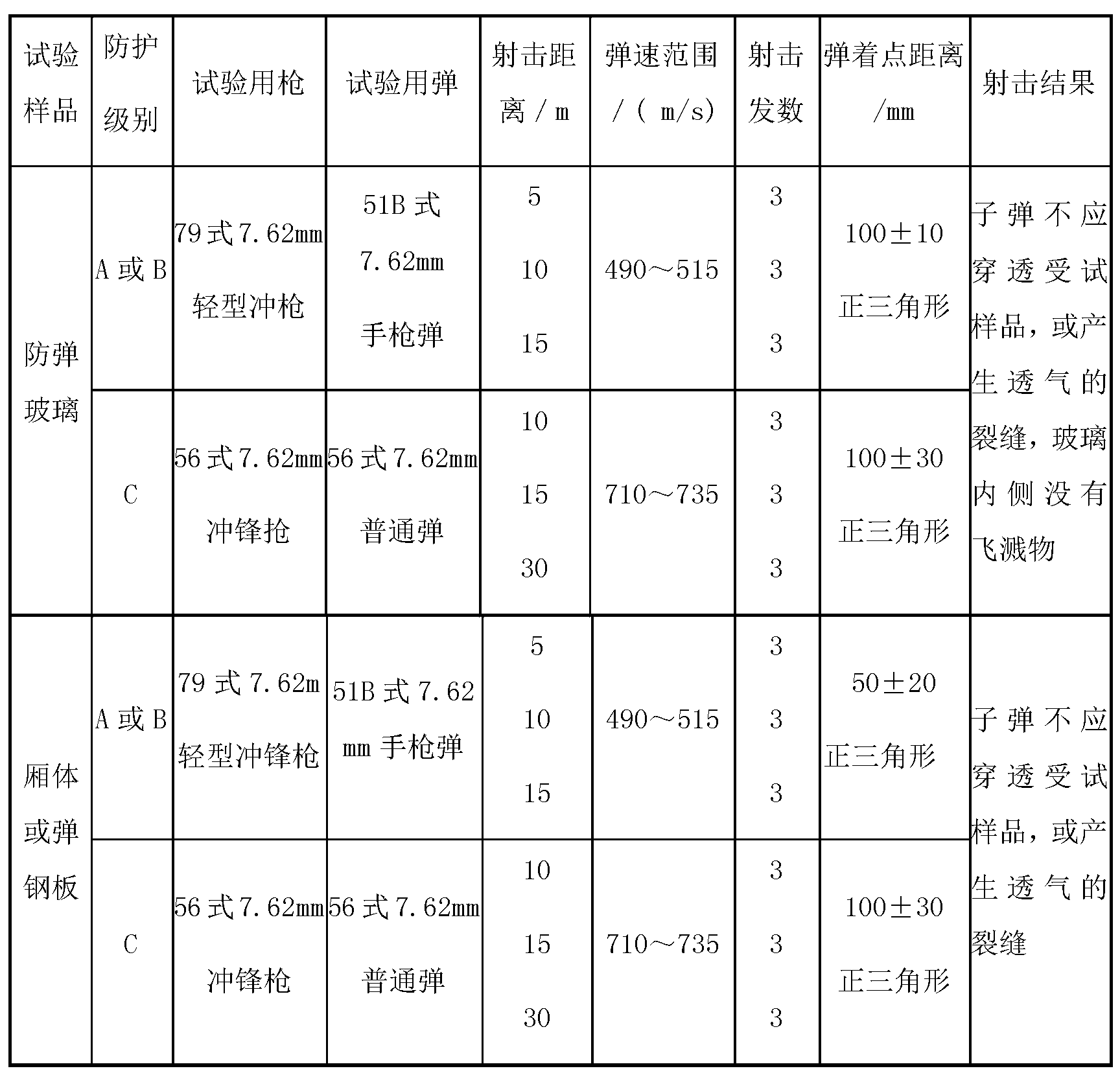

[0025] A soft, tough and impact-resistant composite material body, which is a body or an assembled combination formed by vulcanizing at high temperature together with multi-layer composite rubber, multi-layer soft wire or soft steel wire and skeleton spring or spring leaf. Multiple layers of bulletproof cloth are sandwiched in the composite rubber layer to make a car body or assembled combination with impact resistance and bulletproof functions.

[0026] The composite rubber is made of the following raw materials by weight: 100kg of natural rubber, 2kg of stearic acid, 4kg of zinc oxide, 1.5kg of sulfur, 48kg of carbon black N220, 1.5kg of accelerator MDB, 11g of antioxidant RD, and 2kg of paraffin wax , Fang Jin oil 7kg.

[0027] The soft silk thread can be woven fabric or various cord fabrics.

[0028] The soft toughness and impact-resistant composite material vehicle body is composed of 8% soft silk or soft steel wire, 20% spring or leaf spring, and 72% composite rubber. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com