Integral controller applied to aeration tank for sewage treatment

A sewage treatment and aeration tank technology, applied in aerobic process treatment, sustainable biological treatment and other directions, can solve the problems of unacceptable, high use cost, and increased control difficulty, so as to facilitate installation and commissioning, ensure water quality, Optimizing the effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0064] The specific implementation is to connect the instruments, sensors and other control lines according to the markings according to the process requirements.

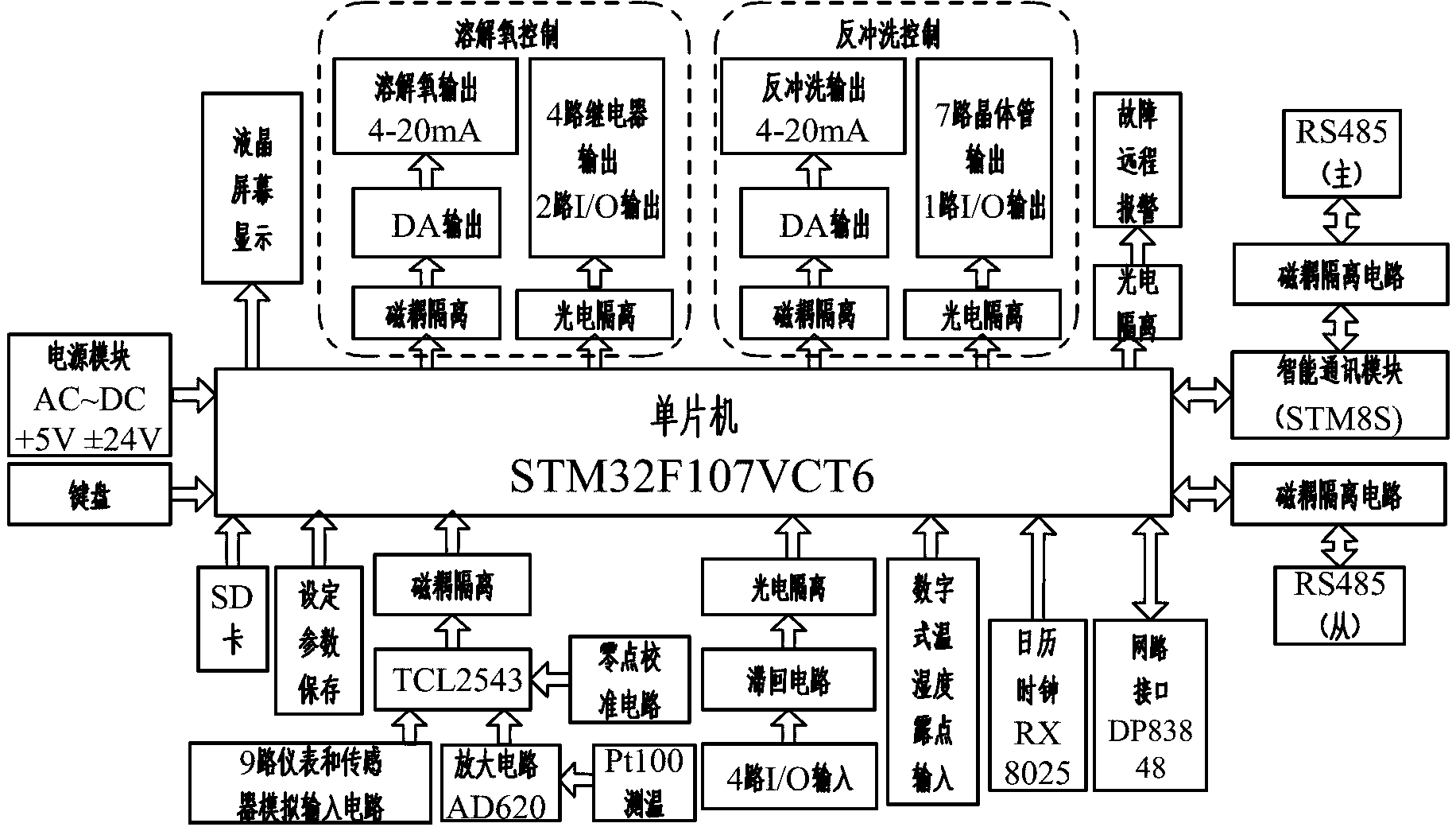

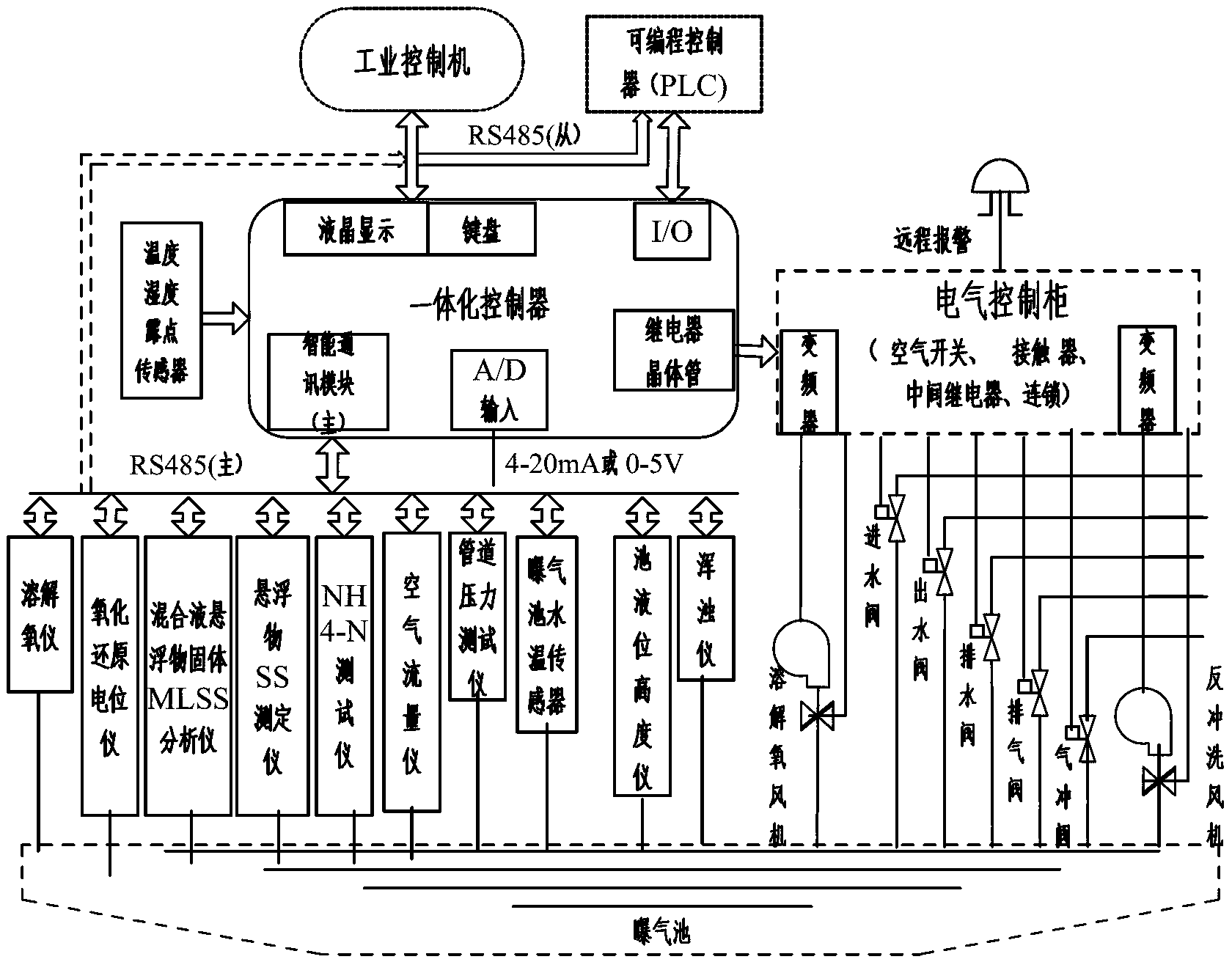

[0065] The integrated controller can be modified on the original control system, and can also be used for the new sewage treatment system. The connection method between the controller and the on-site instrument depends on the specific situation. figure 2 There are three ways to obtain instrument data: 1) analog input; 2) intelligent control communication; 3) host computer. When the user needs to modify the old system or change the instrument manufacturer, he only needs to confirm the instrument data acquisition method when ordering. The intelligent communication module can be replaced at will, and the module is strictly corresponding to the type of instrument. The control mode of the present invention is based on the connected instrument type, and the relevant parameters and control mode are set through the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com