Deep treatment method of synthetic rubber wastewater

A technology for synthetic rubber and treatment method, applied in the field of organic chemical wastewater treatment, can solve the problems of reducing organic content, unstable treatment effect, long treatment process, etc., and achieves reduction of organic content and suspended solids. Effects of membrane fouling conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

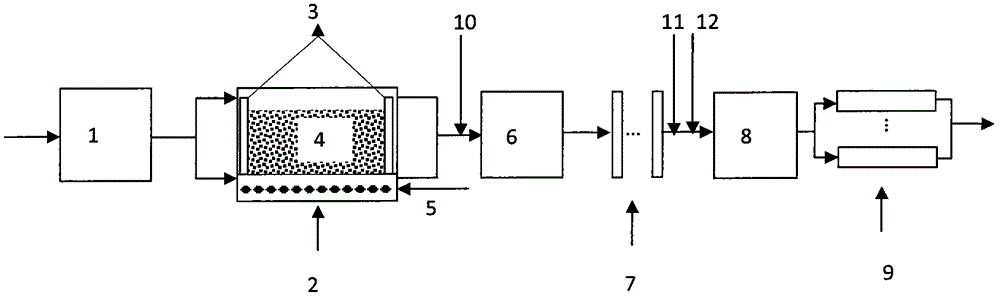

Method used

Image

Examples

Embodiment 1

[0029] After the secondary biochemical treatment of the production wastewater of a synthetic rubber factory, the discharge water has a pH of 6.2, a turbidity of 18NTU, a COD of 112mg / L, a TOC of 30mg / L, and a conductivity of 4460μm / cm.

[0030] The above wastewater is filtered through a multi-media filter at a filtration rate of 7m / h, and the product water enters the fixed-bed three-dimensional electrode electrolysis device, using upward flow. The conditions are as follows: current density is 50A / m 2 , The electrolysis time is 60min. The turbidity of the effluent of the multi-media filter is 2.5-4.5NTU, the cleaning cycle is 48h, the COD of the effluent of the fixed-bed three-electrode electrolysis device is 53mg / L, the COD removal rate is 53%; the TOC is 19mg / L, and the TOC removal rate Is 37%.

[0031] Add sodium hypochlorite to the effluent at a dosage of 3mg / L, then pass through a bag filter and enter the ultrafiltration system with a flux of 85LMH and an operating pressure of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com