Retarder matched with magnesia expansive agent and preparation method thereof

A technology of expansion agent and retarder, which is applied in the field of retarder and its preparation, can solve problems such as difficulty in use, loss of reactivity of magnesium oxide expansion agent, and decline in expansion performance, so as to achieve convenient purchase, expansion performance not weakened, The effect of improving liquidity retention ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add the following raw materials into the reaction kettle according to their mass percentages, and mix and stir evenly at room temperature to prepare the retarder:

[0028] Ammonium phosphate 20%;

[0029] Ammonium Citrate 30%;

[0030] Water 45%.

Embodiment 2

[0032] Add the following raw materials into the reaction kettle according to their mass percentages, and mix and stir evenly at room temperature to prepare the retarder:

[0033] Ammonium oxalate 8%;

[0034] Ammonium phosphate 15%;

[0035] Ammonium Citrate 27%;

[0036] Water 50%.

Embodiment 3

[0038] Add the following raw materials into the reaction kettle according to their mass percentages, and mix and stir evenly at room temperature to prepare the retarder:

[0039] Ammonium oxalate 10%;

[0040] Ammonium phosphate 10%;

[0041] Ammonium citrate 20%;

[0042] Water 60%.

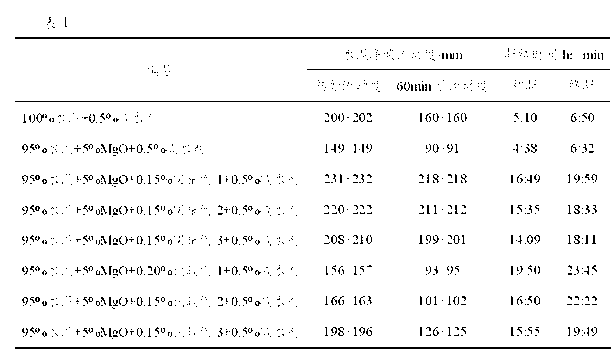

[0043] In the present invention, the retarder is added to the cementitious material, and the influence of the retarder on the fluidity and retarding effect of the cementitious slurry is evaluated by the slurry test, and the test method of the fluidity of the cementitious slurry is referred to GB8077-2000 " The relevant provisions of the "Concrete Admixture Homogeneity Test Method" are implemented, and the test method of the setting time of the cementitious slurry is implemented in accordance with the relevant provisions of GB / T1346-2011 "Cement Standard Consistency Water Consumption, Setting Time, and Stability Test Method".

[0044] In the application examples of the present invention, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com