A kind of high-efficiency shrinkage-reducing anti-cracking agent and preparation method thereof

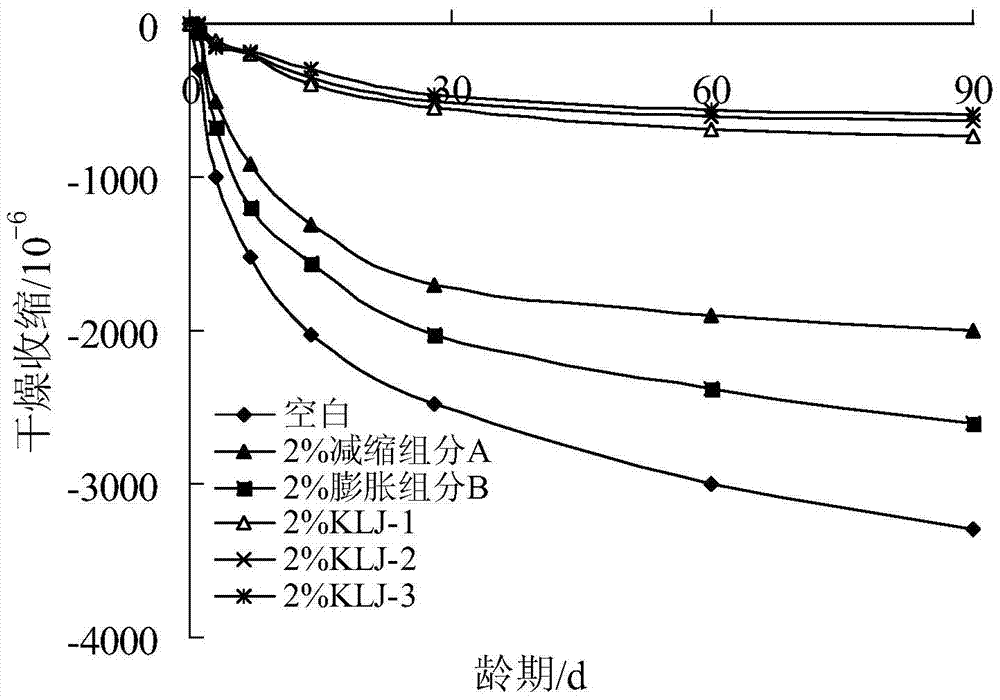

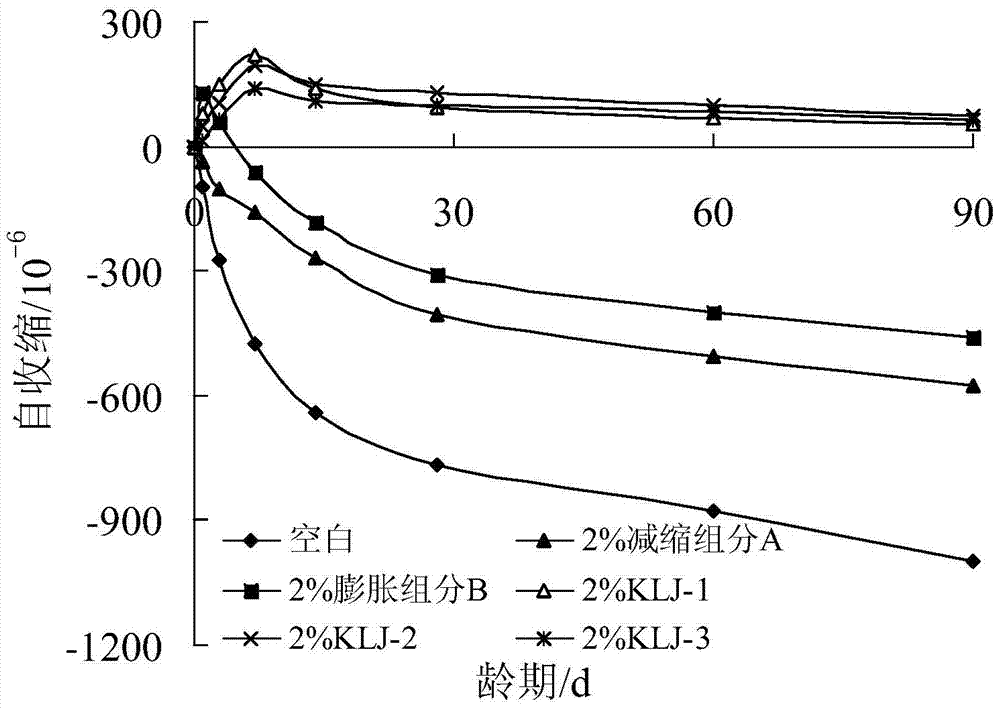

A technology of anti-cracking agent and shrinkage reducing agent, which is applied in the field of high-efficiency shrinkage-reducing anti-cracking agent and its preparation, which can solve the problems of concrete strength loss, less active ingredients, and high cost, so as to improve expansion effectiveness, delay early hydration, and improve The effect of crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] 1. Preparation of shrinkage-reducing components

[0018] 2 parts of polyethylene glycol monoallyl ether, 2 parts of methoxy polyethylene glycol methacrylate and 1 part of styrene were mixed and added to the reaction kettle, and the mixture was mixed according to polyethylene glycol monoallyl ether and 1 part of styrene. The molar ratio of hydrogen peroxide is 5:1, adding 0.1 mol / L hydrogen peroxide solution as a proportioning ingredient, heating the temperature of the reactor to 65°C, and then adding 0.5 part of polyacrylamide and 0.1 part of ammonium persulfate initiator simultaneously to react In the kettle, separate dropwise addition, the dropwise addition time is 60min, after the dropwise addition is completed, the reaction is incubated for 3h, and after the reaction is completed, alkali is added to neutralize to pH=7.1, to obtain a light milky white transparent liquid with a solid content of 46.3%, a molecular weight of 49000, Liquid Shrinkage Reducing Component A ...

Embodiment 1

[0021] Take 65 parts of f-CaO with a content of 65% and a particle size of 900 meshes of commercially available calcium oxide expansion agent as the expansion component and add it to the powder feeder of the spray drying tower, and feed the gas with a pressure of 0.5MPa to expand the component. It is transported to the front end of the hot air distributor at the top of the drying tower, and hot air with a temperature of 190 ° C is introduced to quickly dry the expanded components and evenly disperse them in the hot air. Turn on the spray drying tower, and when the temperature of the feed port at the top of the spray drying tower is 120°C, 35 parts of the above-mentioned liquid shrinkage-reducing components are transported to the liquid feed port at the top of the spray drying tower by the screw pump, and the liquid feed port is passed through the liquid feed port. The high-speed centrifugal atomizing disc atomizes the liquid shrinkage-reducing components into micro-droplets wit...

Embodiment 2

[0023] Take 60 parts of f-CaO with a content of 65% and a particle size of 900 meshes of commercially available calcium oxide expansion agent as the expansion component and add it to the powder feeder of the spray drying tower, and feed the gas with a pressure of 0.4MPa to expand the component. It is transported to the front end of the hot air distributor at the top of the drying tower, and hot air with a temperature of 180 ° C is introduced to quickly dry the expanded components and evenly disperse them in the hot air. Turn on the spray drying tower, and when the temperature of the feed port at the top of the spray drying tower is 125°C, 40 parts of the above-mentioned liquid shrinkage-reducing components are transported to the liquid feed port at the top of the spray drying tower by the screw pump. The high-speed centrifugal atomizing disc atomizes the liquid shrinkage-reducing components into micro-droplets with a droplet diameter of 50-100 microns. The moisture in the drop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com