Olefin separation system and olefin separation method

A technology for olefin separation and hydrocarbon enrichment, which is applied in hydrocarbon purification/separation, distillation purification/separation, adsorption purification/separation, etc. It can solve the problems of high energy consumption, high investment, and large loss of ethylene, and achieve energy consumption reduction , reduce investment and operating costs, reduce the effect of ethylene loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that the embodiments in the present application and the features of the embodiments may be combined with each other in the case of no conflict. The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

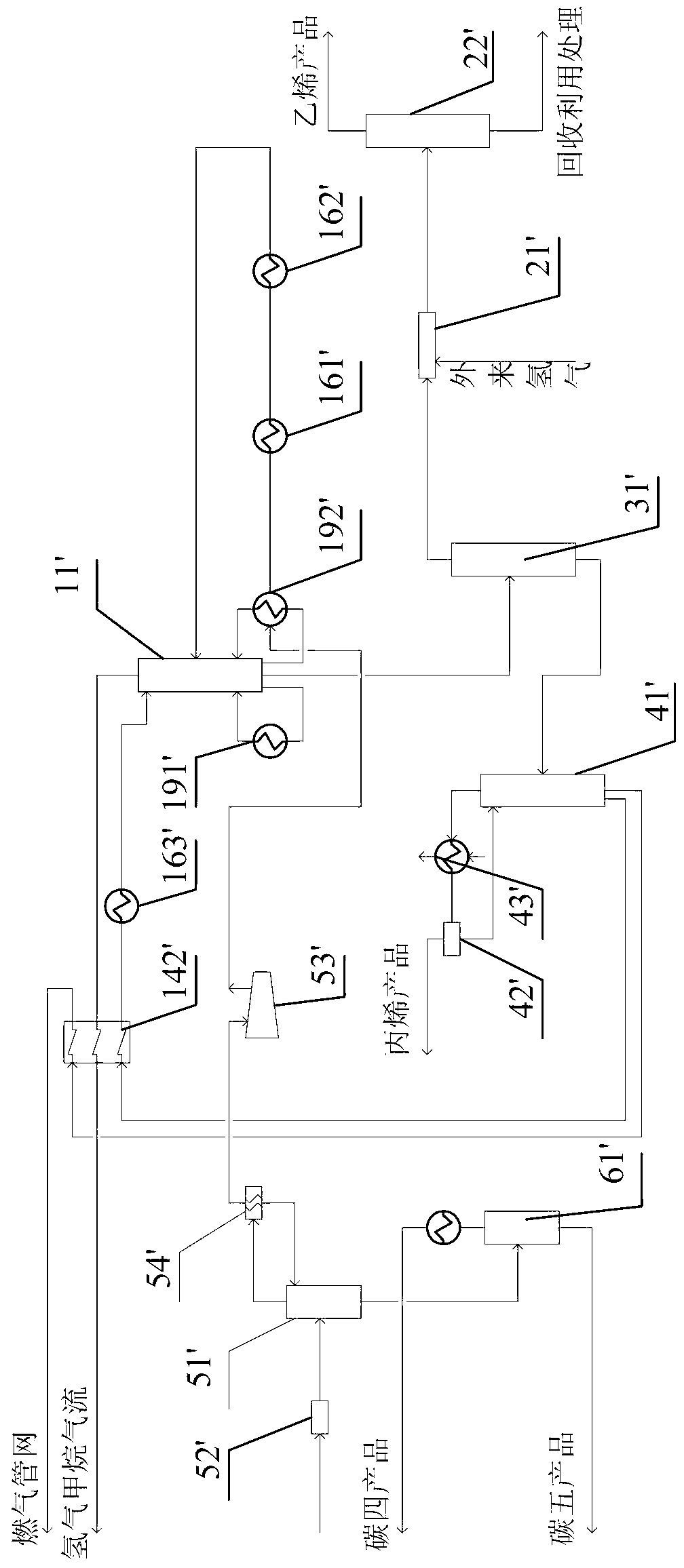

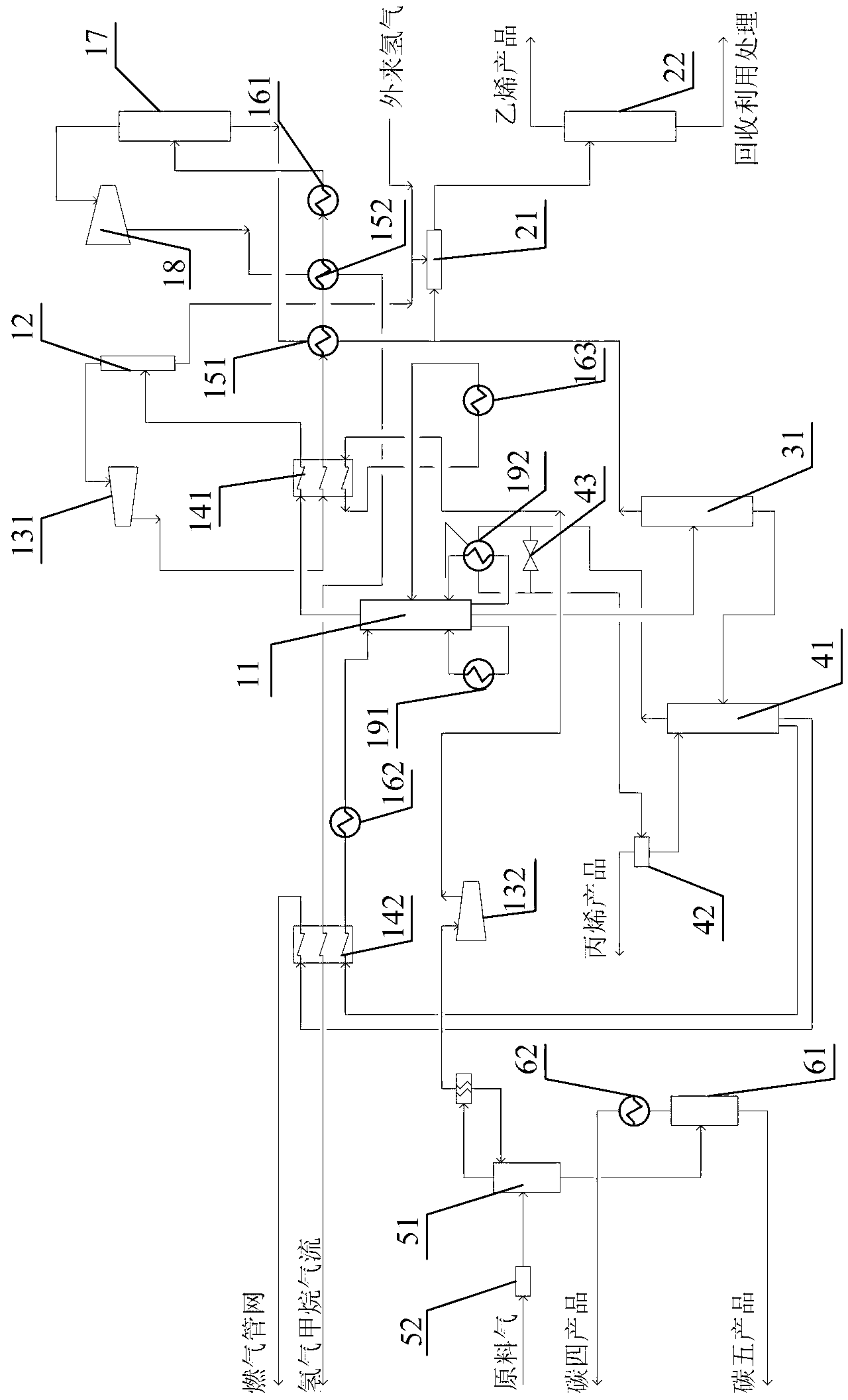

[0024] like figure 2 As shown, in a typical embodiment of the present invention, a kind of olefin separation system is provided, and this olefin separation system comprises demethanization unit, and demethanization unit comprises primary demethanizer 11, pressure swing adsorption system 12 and secondary demethanizer Tower 17, the first gas phase flow pipeline is arranged between the tower top outlet of the initial demethanizer 11 and the inlet of the pressure swing adsorption system 12; There are hydrocarbon-rich gas flow lines.

[0025] The olefin separation system with the above structure is used in conjunction with the primary demethanizer 11, the pressure swing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com