Method for preparing alginate oligosaccharide monomers by using microwave radiation

A technology of alginic acid oligosaccharide and microwave irradiation, applied in the field of medicinal chemistry, can solve the problems of long preparation period, cumbersome process, unable to obtain monomers of oligosaccharide, etc., and achieves easy separation and purification, simple post-processing and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Preparation of mannuronic acid oligosaccharide monomer

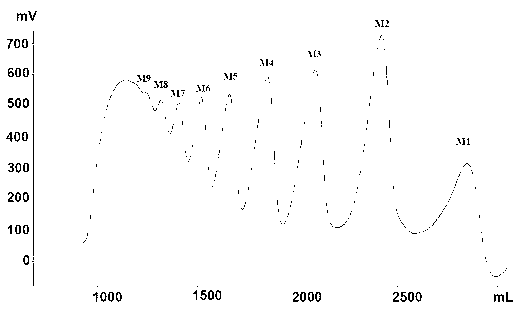

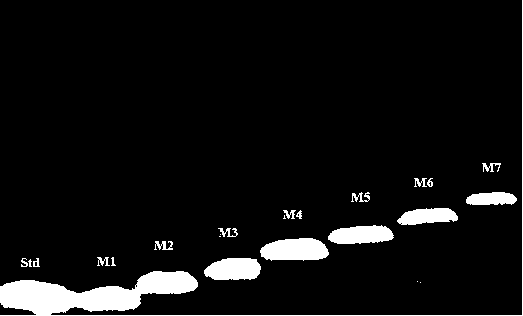

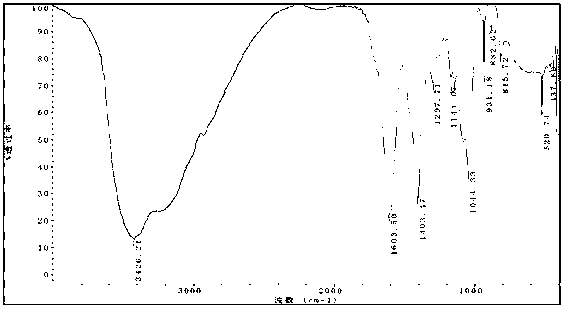

[0030] Polymannuronic acid (Mw=6.7kD) (the preparation method of polymannuronic acid described in the present invention is to adjust the pH value of the low molecular weight alginic acid solution to 2.85, the supernatant is graded with 75% ethanol, and the obtained precipitate is Polymannuronic acid) was prepared into a solution or suspension with a concentration of 100g / L in pure water, and ultrasonicated for 1min to fully dissolve it. Add the solution or suspension to 3 microwave extraction tanks (30mL per tank), microwave degradation at 140°C for 30min under the power of 400W, after the product is cooled, filter through double-layer filter paper, and freeze-dry to obtain mannuraldehyde Acid-oligosaccharide mixture, its yield was 86.9%. Its weight-average molecular weight was determined to be 2254 Da by HPGPC method. The oligosaccharide mixture was separated and purified by Bio-Gel P6 column chro...

Embodiment 2

[0037] Embodiment 2: Preparation of mannuronic acid oligosaccharide monomer

[0038] Prepare polymannuronic acid (Mw=10.6kD) into a suspension with a concentration of 5g / L in pure water, and ultrasonicate for 1min to fully dissolve it. Put it into 8 microwave digestion tanks (2mL per tank), set the power at 800W, microwave degradation at 90°C for 20 minutes, after the product is cooled, filter through double-layer filter paper, and freeze-dry to obtain the mannuronic acid oligosaccharide mixture. The yield was 84.4%. Its weight-average molecular weight was determined to be 3627 Da by HPGPC method. The oligosaccharide mixture was separated and purified by Bio-Gel P4 column chromatography (column volume is 4000mL), with 0.1mol / L NH 4 HCO 3 As the mobile phase, set the flow rate to 2.5mL / min, collect 10mL in each tube, detect with a differential detector, collect samples according to peaks, and heat to remove NH 4 HCO 3 Finally, oligosaccharide monomers with different polyme...

Embodiment 3

[0039] Embodiment 3: Preparation of mannuronic acid oligosaccharide monomer

[0040] Prepare polymannuronic acid (Mw=6.7kD) into a suspension with a concentration of 200g / L in pure water, and sonicate for 1min to fully dissolve it. Add it to 16 microwave digestion tanks (2mL per tank), and microwave degradation at 110°C for 15min under the condition of power of 1600W. After the product is cooled, it is filtered with double-layer filter paper and freeze-dried to obtain a mixture of mannuronic acid oligosaccharides. The yield was 84.4%. Its weight-average molecular weight was determined to be 2954 Da by HPGPC method. The oligosaccharide mixture was separated and purified by Superdex30 column chromatography (column volume is 2000mL), with 0.1mol / L NH 4 HCO 3 As the mobile phase, set the flow rate to 1.5mL / min, collect 3mL in each tube, detect with a differential detector, collect samples according to peaks, and heat to remove NH 4 HCO 3 Finally, oligosaccharide monomers with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com