A kind of heavy hydrocarbon raw material hydrotreating method

A technology for hydroprocessing and raw materials, which is applied in the fields of hydroprocessing process, hydrocarbon oil treatment, petroleum industry, etc. It can solve problems such as unfavorable conditions, prolonging the operation period, shutdown of residual oil hydrogenation equipment, etc., and achieves high reaction heat and improved reaction Performance, responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

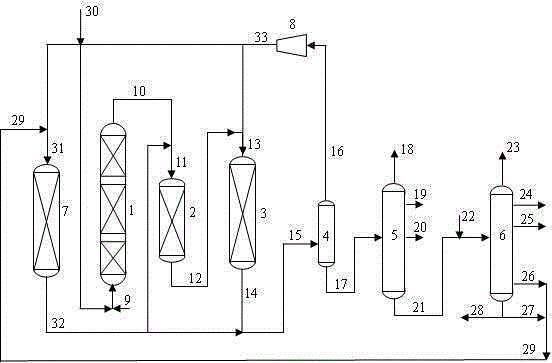

[0048] Embodiment 1 comprises four reactors, an upflow type reactor (UFR) and three downflow type fixed bed reactors, wherein a downflow type fixed bed reactor is placed in UFR upstream according to the technological process of the present invention, as pre-reaction The other two downflow fixed-bed reactors are located downstream of UFR and used in series with UFR. Upflow catalyst FZC-10UH is loaded in the upflow reactor, protective agent FZC-103 and demetallization catalyst FZC-28 are loaded in the first fixed bed reactor (referred to as fixed bed first reactor), and the second fixed bed reactor (fixed bed for short) is filled with FZC-28 The desulfurization catalyst FZC-34A and denitrification catalyst FZC-41A are loaded in the second bed reactor, and the pre-reactor is filled with protective agent FZC-103, demetallization catalyst FZC-28 and desulfurization catalyst FZC-34A.

[0049]See Table 1 for the properties of the mixture of catalytic cracking re-refinery oil and cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com