Oily biomass wood dust particle fuel formula with high combustion value and preparation method thereof

A particle fuel, combustion value technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve problems such as screw shaft wear, achieve the effect of good compression ratio, prolong mechanical life, reduce wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

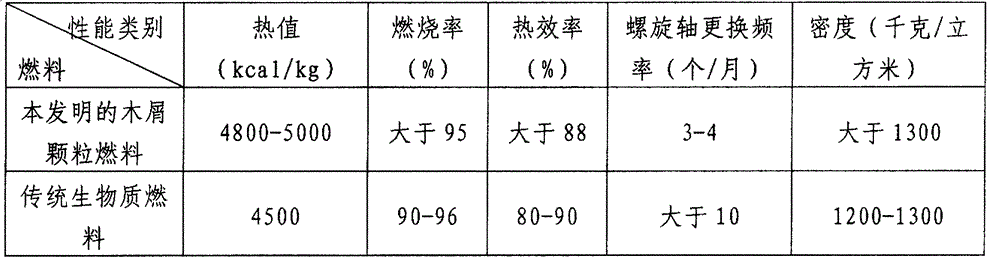

Image

Examples

Embodiment 1

[0020] Example 1: Oily biomass wood pellet fuel with high combustion value comprises the following raw materials in parts by weight: 90 parts of wood chips, 9 parts of hawthorn seeds, and 1 part of peanut shells.

[0021] The preparation method of the oily biomass sawdust pellet fuel of high combustion value, it comprises the following steps:

[0022] (a) Pulverization: pulverize wood chips into tiny particles of 1.5mm;

[0023] (b) drying: drying the sawdust particles obtained in step (a) to 7% through a rotary drum dryer;

[0024] (c) mixing: mixing the sawdust particles obtained in step (b) with hawthorn seeds and peanut shells to prepare a mixed material;

[0025] (d) Extrusion: Extrude and granulate the mixed material obtained in step (c), with an extrusion length of 3 cm and a diameter of 0.6 cm, to obtain an oily biomass wood pellet fuel with a high combustion value;

[0026] (e) Cooling: the resulting oily biomass wood pellet fuel with high combustion value was place...

Embodiment 2

[0028] Example 2: Oily biomass wood pellet fuel with high combustion value comprises the following raw materials in parts by weight: 80 parts of wood chips, 11 parts of hawthorn seeds, and 2 parts of peanut shells.

[0029] The preparation method of the oily biomass sawdust pellet fuel of high combustion value, it comprises the following steps:

[0030] (a) Pulverization: pulverize wood chips into tiny particles of 1.8mm;

[0031] (b) drying: drying the sawdust particles obtained in step (a) to 6% through a rotary drum dryer;

[0032] (c) mixing: mixing the sawdust particles obtained in step (b) with hawthorn seeds and peanut shells to prepare a mixed material;

[0033] (d) Extrusion: Extrude and granulate the mixed material obtained in step (c), with an extrusion length of 2 cm and a diameter of 0.7 cm, to obtain an oily biomass wood pellet fuel with a high combustion value;

[0034] (e) Cooling: the resulting oily biomass wood pellet fuel with high combustion value was pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com