Process method for preparing hexagonal phase ZnS film at low temperature

A process method and hexagonal phase technology, which is applied in the field of low-temperature preparation of hexagonal ZnS thin films, can solve the problems that the hexagonal phase ZnS thin films have not mentioned, and achieve the effects of dense adhesion, increased lattice matching, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

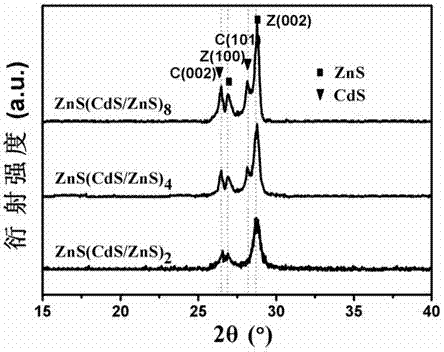

[0017] The targets for depositing films are respectively made of ZnS powder and CdS powder through a press with a uniaxial pressure of 18-20 tons to press the powder into a circular target with a diameter of 3.5 cm and a thickness of 3 mm, and then solid-state sintering at atmospheric pressure The method is to heat up to 1100°C in a tube furnace, and maintain it for 100 minutes for sintering, and then cool to room temperature naturally to obtain ZnS and CdS targets, and the prepared ZnS and CdS targets are all hexagonal phase structures by measurement and analysis; The purity of the ZnS powder and the CdS powder is 99.99%.

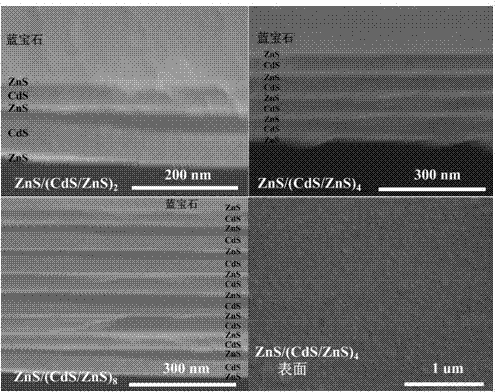

[0018] Select sapphire as the substrate, place the sapphire substrate in deionized water and alcohol successively, after 30 minutes of microwave ultrasonication, rinse and dry with deionized water, and place it in the substrate tank of the vacuum chamber of the pulsed laser deposition instrument. At the same time, the prepared ZnS and CdS targets were resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com