Bone repair material as well as preparation method and application thereof

A technology for bone repair and scaffold materials, applied in the field of medical materials, can solve the problems of poor bone induction, increased surgical procedures, implantation risks and medical expenses, and inability to guarantee three-dimensional three-dimensionality, so as to promote regeneration and reconstruction, simplify Clinical treatment steps, the effect of shortening treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

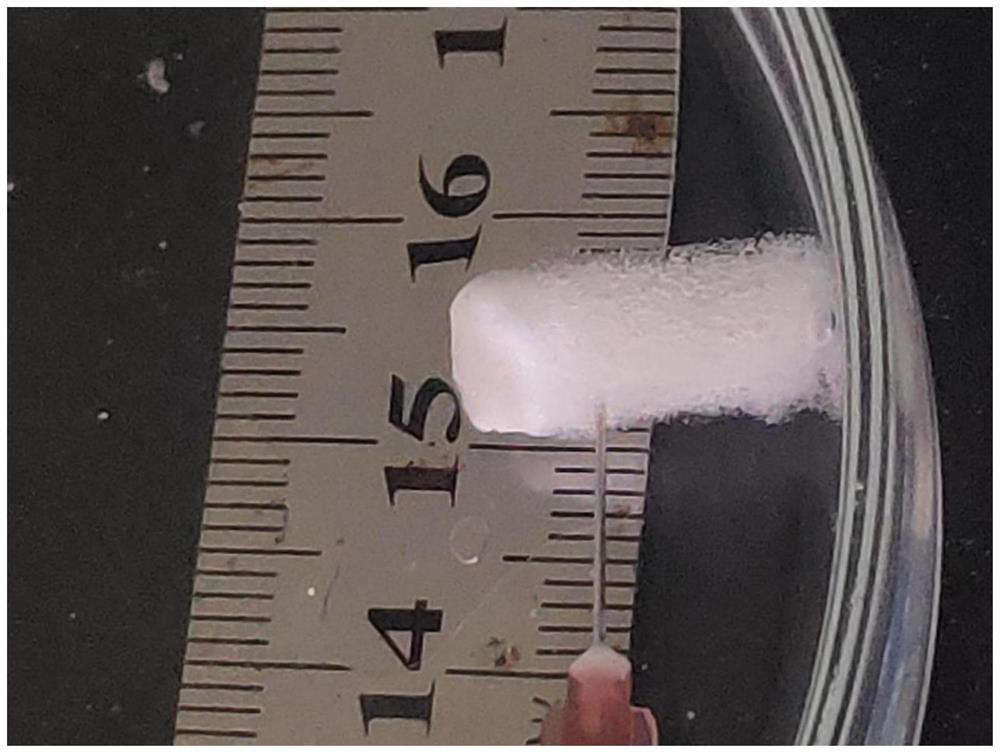

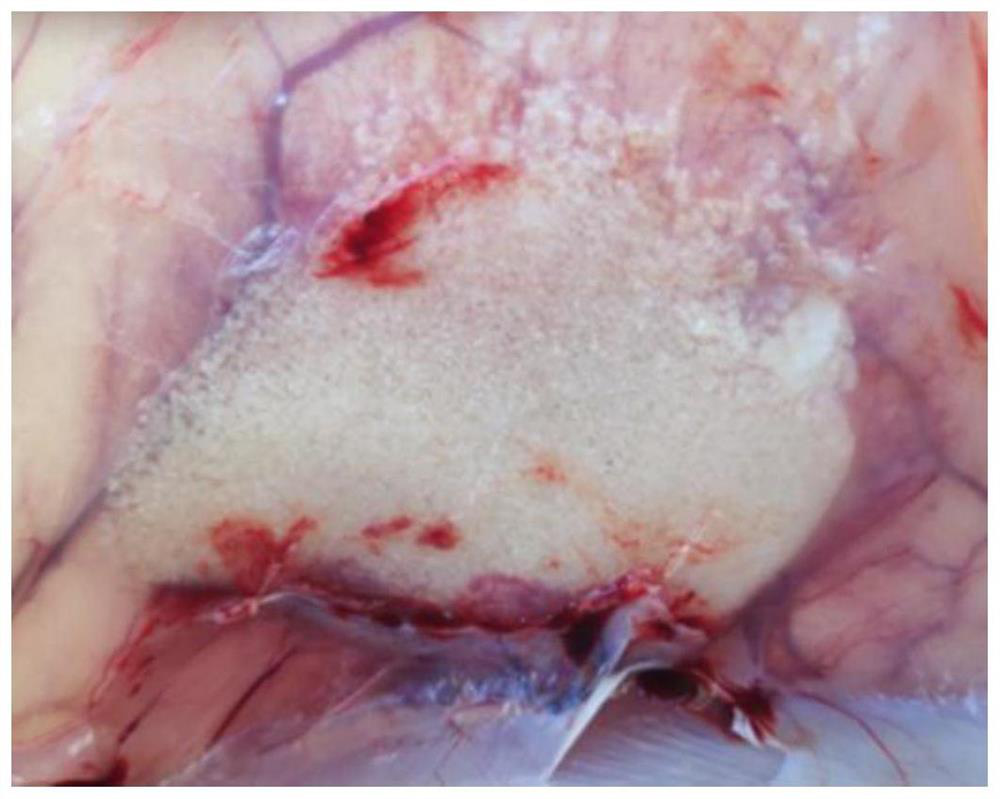

[0075] A preparation method of the above-mentioned bone repair material, comprising the following steps:

[0076] (1) mixing the bone meal, gelatin microspheres and collagen scaffold material in the core material raw material with water, putting it into a mold, and freeze-drying to obtain a core material;

[0077] (2) Mixing the gelatin microspheres and the collagen scaffold material in the raw material of the coating layer with water, adding the core material obtained in step (1), and performing freeze-drying after mixing. Further, the volume ratio of the core material and the raw material of the wrapping layer in step (2) is 1:(0.5-1.5).

[0078] Further, the preparation method of the bone repair material comprises the following steps:

[0079] (1) mixing the bone meal, gelatin microspheres and collagen scaffold material aqueous solution in the core material raw material, putting it into a mold, and freeze-drying to obtain a core material;

[0080] (2) Mixing the gelatin m...

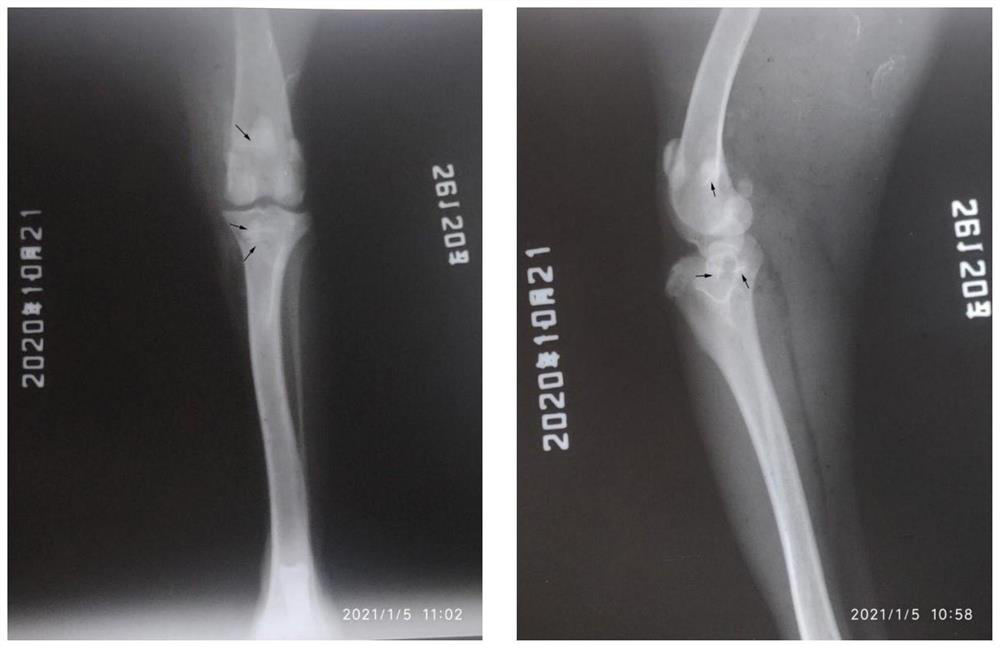

Embodiment 1

[0092] 1) The bovine cancellous bone is cut into bone blocks, soaked in a calcium hydroxide solution with a concentration of 1.0 mol / L at 55° C. for 24 hours, detergent (triton-100) (mass ratio of bone block to triton-100 is 50: 1) Soak at room temperature for 24 hours, repeat once. After repeated rinsing with deionized water, immersed in 0.5mol / L hydrochloric acid solution for 24 hours, after repeated rinsing with deionized water, soaked in 3wt% alkaline phosphatase aqueous solution at 37°C for 24 hours, rinsed repeatedly with phosphate balanced salt solution, dried and pulverized Molecular sieve, made into bone meal with a particle size of 0.5-1.0mm;

[0093]2) Mix carboxymethyl cellulose, sodium alginate and collagen in proportion (mass ratio 1:1:2), add distilled water (the ratio of polymer mixture mass (gram) to solvent volume (ml) is 4:50-75 ) is made into a viscous solution as a stent material solution;

[0094] 3) Add medicinal gelatin to 10wt% lidocaine aqueous solu...

Embodiment 2

[0098] 1) Cut bovine cancellous bone into bone blocks, soak them in a sodium hydroxide solution with a concentration of 0.5 mol / L for 24 hours at 45° C. 10:1) Soak in solution for 24 hours at room temperature, repeat once. After repeated rinsing with deionized water, immersed in 0.5mol / L hydrochloric acid solution for 24 hours, after repeated rinsing with deionized water, immersed in 3wt% alkaline phosphatase solution at 37°C for 24 hours, rinsed repeatedly with phosphate balanced salt solution, dried and crushed Molecular sieve, made into bone meal with a particle size of 0.5-1.0mm;

[0099] 2) Mix carboxymethyl cellulose, sodium alginate and collagen in proportion (mass ratio 1:2:2), add distilled water (the ratio of polymer mixture mass grams to solvent volume milliliters is 4 grams: 50-75 milliliters) to make Viscous solution, as a solution for stent material;

[0100] 3) Add medicinal gelatin to 10wt% lidocaine solution (weight of gelatin (g): volume of lidocaine soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com