Ultrahigh-boost highly-mixed combustion-promoting high-lean-burn ultrahigh-energy-saving huge-power combustion motor main component

An ultra-high pressure, internal combustion engine technology, applied in the direction of engine components, combustion engines, internal combustion piston engines, etc., to achieve the effect of strong practicability, simple structure and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

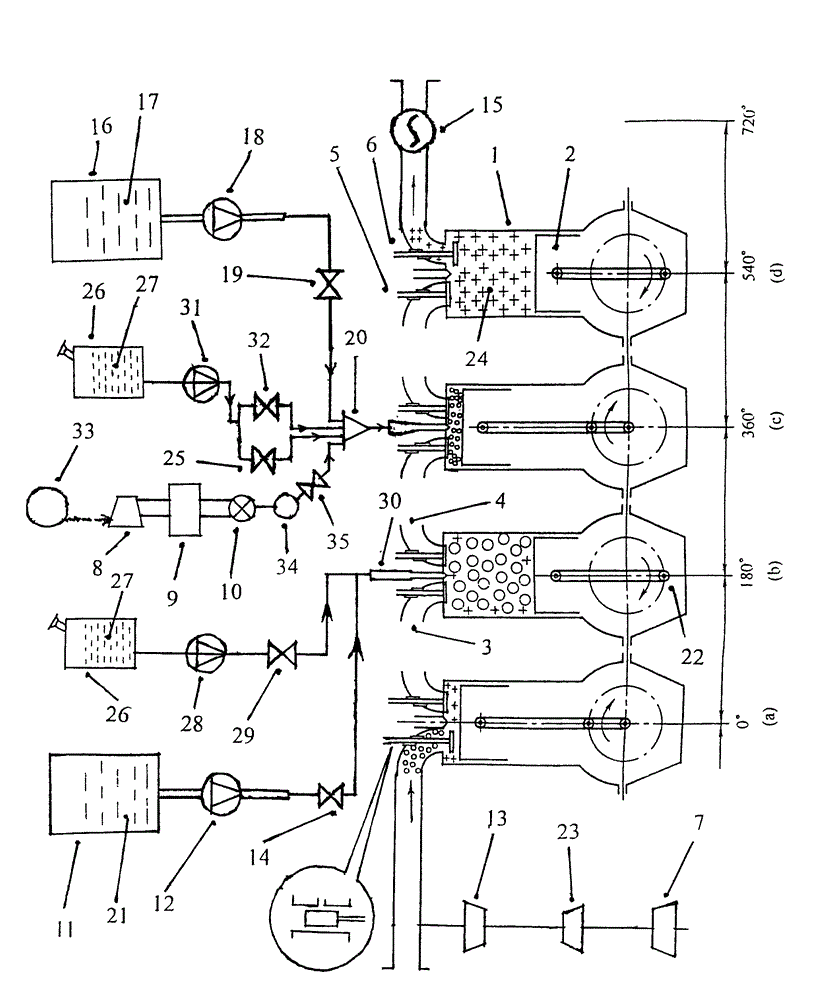

[0010] exist figure 1Among them, the piston (2) is set on the high-pressure cylinder (1), the shutter intake valve (5) and the shutter exhaust valve (6) are connected to the upper part of the high-pressure cylinder (1), and the high-pressure cylinder (1) is set High-temperature, high-lean combustion, ultra-high reaction rate, high-mixing rate, high-speed combustion promotion and ignition forced combustion chamber (24), a connection shutter intake valve (5) is set on the intake channel (3), and a shutter intake valve (5) is set on the exhaust channel (4) Connect the shutter exhaust valve (6). The upper part of the high-pressure cylinder (1) is provided with a high-pressure multi-pulse injector (30), and the high-pressure multi-pulse injector (30) is provided with a water-alcohol mixed liquid tank (11), a high-pressure pump (12), and a water-alcohol agent. Mixed fluid high-pressure input control system (14), set on the high-pressure multi-pulse injector (30) to connect the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com