Organic light-emitting device and preparation method thereof

An electroluminescent device and luminescent technology, which is applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the influence of high refractive index scattering layer flatness, insufficient light output efficiency, and photoresist refraction. Low efficiency and other problems, to achieve good flatness, improve the refractive index, and improve the light output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

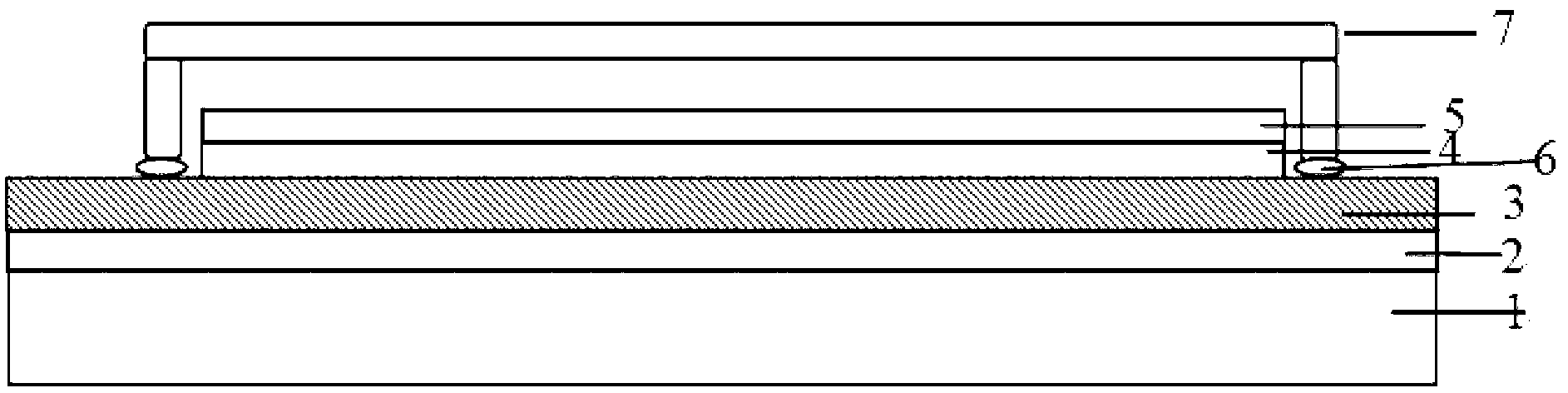

[0062] This embodiment provides an organic electroluminescence device, comprising a substrate 1 and a scattering layer 2, a first electrode 3, an organic functional layer 4 and a second electrode 5 sequentially formed on the substrate 1, and the scattering layer 2 is composed of The following components are prepared: first particle size scattering particles: 18 parts by weight; second particle size scattering particles: 9 parts by weight; dispersant: 8 parts by weight; photoresist: 60 parts by weight; The particle size ratio of the first-size scattering particles and the second-size scattering particles is 20:1.

[0063] A method for preparing the above-mentioned organic electroluminescent device is provided in this embodiment, comprising the following steps:

[0064] S1: cleaning and drying the substrate 1;

[0065] S2: forming a scattering layer 2 on the substrate 1;

[0066] S3: forming a first electrode 3, an organic functional layer 4 and a second electrode 5 by vapor d...

Embodiment 2

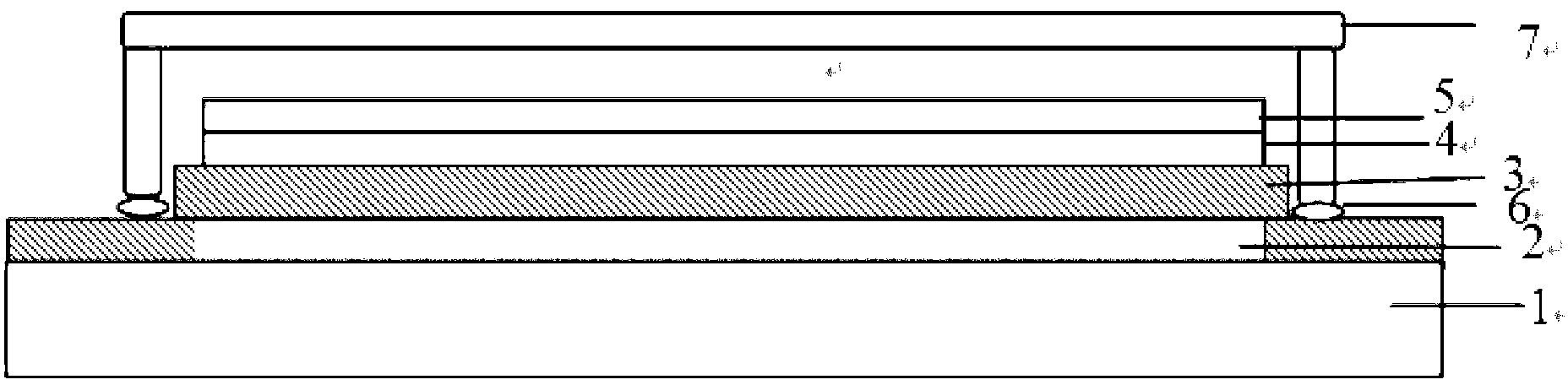

[0092] This embodiment makes the following improvements on the basis of Embodiment 1. In this embodiment, when preparing the scattering layer 2, the scattering particles with the first particle size are selected as ZrO 2 , whose particle size is 800nm, accounting for 10 parts by weight; the second particle size scattering particles are selected as ZrO 2 , whose particle size is 50nm, accounts for 30 parts by weight; titanium dioxide dispersant, accounts for 20 parts by weight;

[0093] Propylene glycol methyl ether acetate is as organic solvent, and weight selection is 70g;

[0094] In this embodiment, the thickness of the scattering layer is 0.3um.

Embodiment 3

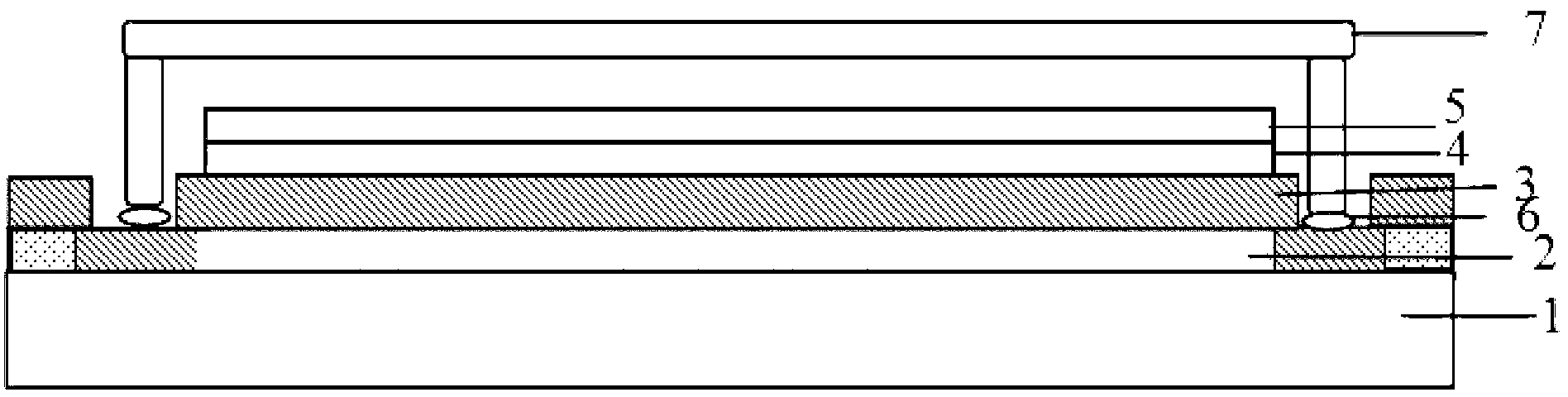

[0096] This embodiment makes the following improvements on the basis of embodiment 1. The method for preparing the scattering layer 2 provided by this embodiment includes the following steps:

[0097] S2A: Select the scattering particles with the first particle size to be SiO 2 , whose particle size is 200nm, accounting for 60 parts by weight; the second particle size scattering particles are selected as SiO 2 , its particle size is 1nm, accounting for 5 parts by weight; the titanium dioxide dispersant is: 60 parts by weight;

[0098] Select photoresist to be ZEOCOAT photoresist, 50 parts by weight, and the light transmittance of described photoresist is 80%;

[0099] Described organic solvent selects propylene glycol methyl ether acetate, and the weight selection is 50g;

[0100] S2B, using a filter paper with a filter pore diameter of 0.9um to press filter the grinding dispersion to obtain a membrane-forming solution;

[0101] S2C, the film forming solution is spin-coated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com