Photosensitive silicone resin composition

A technology of resin composition and silicone, which is applied in the direction of optomechanical equipment, optics, instruments, etc., can solve the problems of loss of transparency of molded body, poor refractive index, large particle size of inorganic filler, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

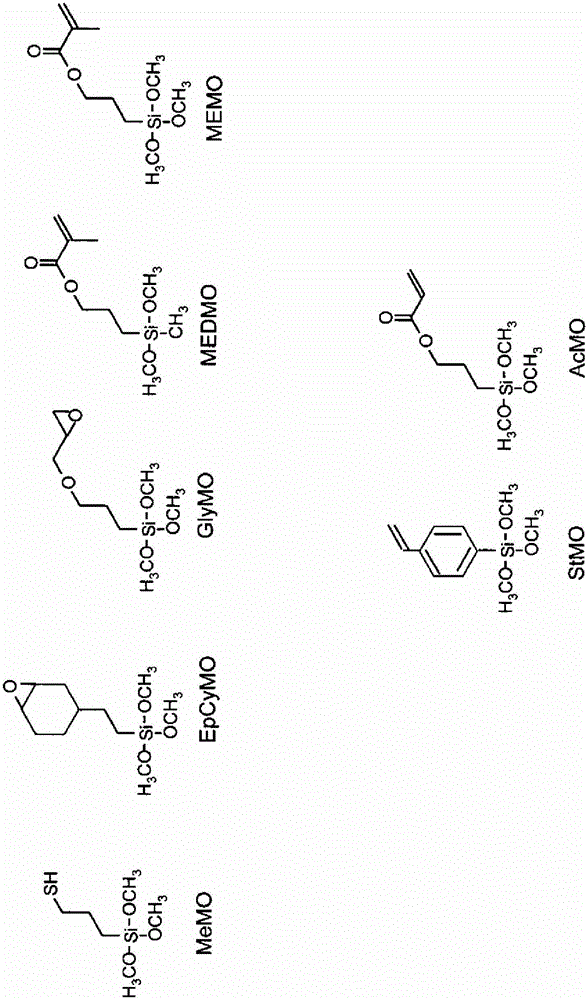

Method used

Image

Examples

Embodiment 1

[0314] In a 500mL eggplant-shaped flask, put 25.76g (0.111mol) of 3-methacryloxypropyl (methyl) dimethoxysilane (hereinafter referred to as MEDMO), 15.10g (0.111mol) of methyl trimethyl Oxysilane (hereinafter referred to as MTMS), 10g of ethanol, and stirred. In another container, 19.96 g of distilled water and 0.004 g of 10% hydrochloric acid were weighed and mixed, and then added dropwise to the aforementioned 500 mL eggplant-shaped flask over 10 minutes using a dropping funnel. After completion of the dropwise addition, a cooling tube was installed, and reflux was performed at 80° C. for 2 hours under a nitrogen stream using an oil bath to obtain a reaction liquid 1 containing a polysiloxane compound (a).

[0315]Into a 500mL eggplant-shaped flask, put 50g of PL-1SL (water-dispersed silica particles with an average primary particle size of 12nm and a concentration of 20% by mass manufactured by Fuso Chemical Industry Co., Ltd.) (Silicon dioxide particles (b)), 50g of ethano...

Embodiment 2

[0320] Into a 500 mL eggplant-shaped flask, 15.46 g (0.067 mol) of MEDMO, 9.06 g (0.067 mol) of MTMS, and 10 g of ethanol were charged and stirred. In another container, 11.97 g of distilled water and 0.004 g of 10% hydrochloric acid were weighed and mixed, and then added dropwise to the aforementioned 500 mL eggplant-shaped flask over 10 minutes using a dropping funnel. After completion of the dropwise addition, a cooling tube was installed, and reflux was performed at 80° C. for 2 hours under a nitrogen stream using an oil bath to obtain a reaction liquid 2 containing a polysiloxane compound (a).

[0321] Into a 500 mL eggplant-shaped flask, 110 g of PL-1SL (silica particles (b)) and 100 g of ethanol were charged and stirred. Next, using the dropping funnel, the reaction solution 2 cooled to room temperature was dropped into the eggplant-shaped flask over 20 minutes, and stirred at room temperature for 30 minutes. After stirring, a cooling tube was installed, and reflux was...

Embodiment 3

[0326] In a 500mL eggplant-shaped flask, put 5.88g (0.025mol) MEDMO, 7.54g (0.030mol) 3-methacryloxypropyltrimethoxysilane (hereinafter referred to as MEMO), 6.67g (0.035mol) Cyclohexylmethyldimethoxysilane (hereinafter referred to as CyMDMS) and 10 g of ethanol were stirred. In another container, 7.65 g of distilled water and 0.004 g of 10% hydrochloric acid were weighed and mixed, and then added dropwise to the aforementioned 500 mL eggplant-shaped flask over 10 minutes using a dropping funnel. After completion of the dropwise addition, a cooling pipe was installed, and reflux was performed at 80° C. for 2 hours under a nitrogen flow using an oil bath to obtain a reaction liquid 3 containing a polysiloxane compound (a).

[0327] Into a 500 mL eggplant-shaped flask, 120 g of PL-1SL (silica particles (b)) and 100 g of ethanol were charged and stirred. Next, using the dropping funnel, the reaction liquid 3 cooled to room temperature was dropped into the above-mentioned eggplan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com