POSS (polysilsesquioxane)-containing polymerizable surfactant and preparation method thereof

A surfactant and polymerization technology, applied in the field of polymerizable surfactants and its preparation, can solve the problems of latex instability, lower water resistance of products, etc., and achieve remarkable results in water pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

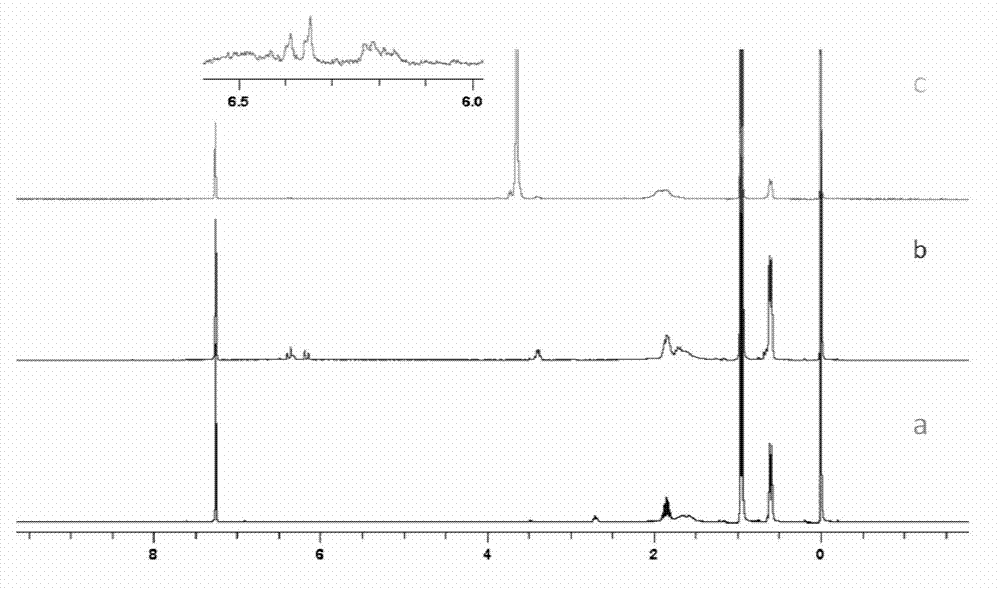

[0027] (1) 10g of aminopropyl isobutyl POSS (its nuclear magnetic resonance spectrum is shown in figure 1 As shown in the spectral line a), 0.96g maleic anhydride (MA) and 0.028g p-diphenol were dissolved in 40mL of benzene, nitrogen was passed through to remove oxygen, and after reacting at 80°C for 12 hours, the benzene ring was evaporated with a rotary evaporator After resembling a solvent, use a volume ratio of 1:1 petroleum ether / diethyl ether mixed solution to extract and then separate and precipitate with a centrifuge to obtain POSS-MA (its nuclear magnetic resonance spectrum is as follows: figure 1 The spectral line b is shown).

[0028] (2) Dissolve 3g POSS-MA, 4.10g polyethylene glycol (PEG-2000), 0.015g p-toluenesulfonic acid and 0.0255g hydroquinone in 40mL benzene, blow nitrogen to remove oxygen, and react at 125°C After 24 hours, use a rotary evaporator to remove the benzene ring solvent, use a mixed solution of petroleum ether / diethyl ether with a volume ratio ...

Embodiment 2

[0035] (1) Dissolve 10.0g of aminopropyl isobutyl POSS, 0.96g of maleic anhydride and 0.1~1% of the total mass of aminopropyl isobutyl POSS and maleic anhydride in 40mL of benzene, and pass Deoxygenate with nitrogen, react at 90°C for 24 hours, evaporate the benzene ring solvent with a rotary evaporator, extract with a mixed solution of petroleum ether / ether with a volume ratio of 1:1, and then separate and precipitate with a centrifuge to obtain POSS-MA.

[0036] (2) Add 3g POSS-MA, 3.91g polyethylene glycol (PEG-400), 0.1~1% p-diphenol, 0.021g p-toluenesulfonate to the total mass of aminopropyl isobutyl POSS and maleic anhydride Dissolve the acid in 40mL of benzene, pass nitrogen gas to remove oxygen, react at 140°C for 24 hours, use a rotary evaporator to remove the benzene ring solvent, use a mixed solution of petroleum ether / diethyl ether with a volume ratio of 1:1 to extract and then Separate the precipitate with a centrifuge to obtain POSS-MA-PEG600 with a yield of 94%...

Embodiment 3

[0039] (1) Dissolve 8.0g of aminopropyl isobutyl POSS, 0.82g of maleic anhydride and 0.1~1% of the total mass of aminopropyl isobutyl POSS and maleic anhydride in 40mL of benzene, and pass Deoxygenate with nitrogen, react at 100°C for 15 hours, evaporate the benzene ring solvent with a rotary evaporator, extract with a mixed solution of petroleum ether / ether with a volume ratio of 1:1, and then separate and precipitate with a centrifuge to obtain POSS-MA.

[0040](2) Add 3g POSS-MA, 3.36g polyethylene glycol (PEG-600), 0.1~1% p-diphenol, 0.024g p-toluenesulfonate to the total mass of aminopropyl isobutyl POSS and maleic anhydride Dissolve the acid in 40mL of benzene, pass nitrogen gas to remove oxygen, react at 130°C for 18 hours, evaporate the benzene ring solvent with a rotary evaporator, use a mixed solution of petroleum ether / diethyl ether with a volume ratio of 1:1 to extract and then Separate the precipitate with a centrifuge to obtain POSS-MA-PEG600 with a yield of 93%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com