Preparation method of epiglloctechin gallate imprinted polymer monolithic column

A technology for epigallocatechin and gallate, which is applied in the field of preparing epigallocatechin gallate molecularly imprinted polymer monolithic columns by in-situ polymerization, can solve the problems of easy oxidation, difficulty in obtaining high purity, and the like, Achieve the effect of easy operation, avoid column packing procedures, and simplify the experimental process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Preparation of epigallocatechin gallate imprinted monolithic column by in situ polymerization:

[0021] a. According to the mass number of the integrated epigallocatechin gallate imprinted column synthesized in a stainless steel column, the template molecule was accurately weighed as epigallocatechin gallate 2.88%, and the functional monomer was acrylamide 5.45% The cross-linking agent is 74.71% ethylene glycol dimethacrylate, the porogen is 5.5% polystyrene dissolved in THF solution (concentration 40mg / ml) and 10.53% isooctane is added, and the initiator is azobis Mix isobutyronitrile 0.93%, ultrasonic for 20 minutes to make it uniform and clear, then transfer to a clean stainless steel column 100×4.6mmI.D., ultrasonic degassing for 15 minutes, seal both ends of the stainless steel column, React in a constant temperature water bath with a temperature of 60°C for 24 hours;

[0022] b. Removal of template molecules: Take out the synthesized stainless steel column and co...

Embodiment 2

[0025] Embodiment 2 (control)

[0026] Separation of Epigallocatechin Gallate and Its Structural Analogues by Blank Monolithic Column

[0027]In order to investigate the retention of epigallocatechin gallate and its structural analogues on non-imprinted columns, a blank column without template epigallocatechin gallate was synthesized as a control. The specific operation steps are as follows:

[0028] Except that the template molecule epigallocatechin gallate was not added, a non-imprinted blank column was synthesized with the same method and experimental conditions as in Example 1. After the polymerization was completed, it was washed with tetrahydrofuran to remove the porogen and residual porogen in the monolithic column. Unreacted reagents;

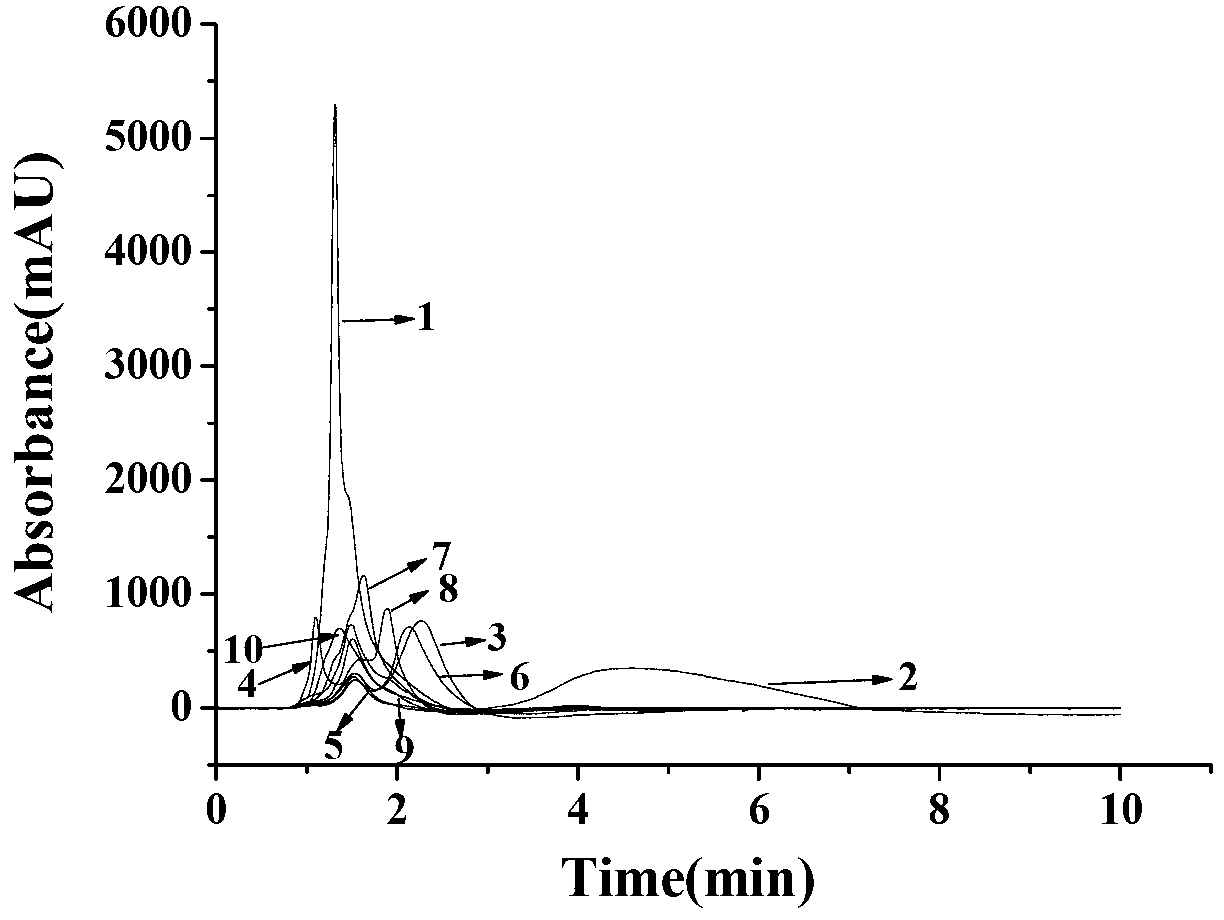

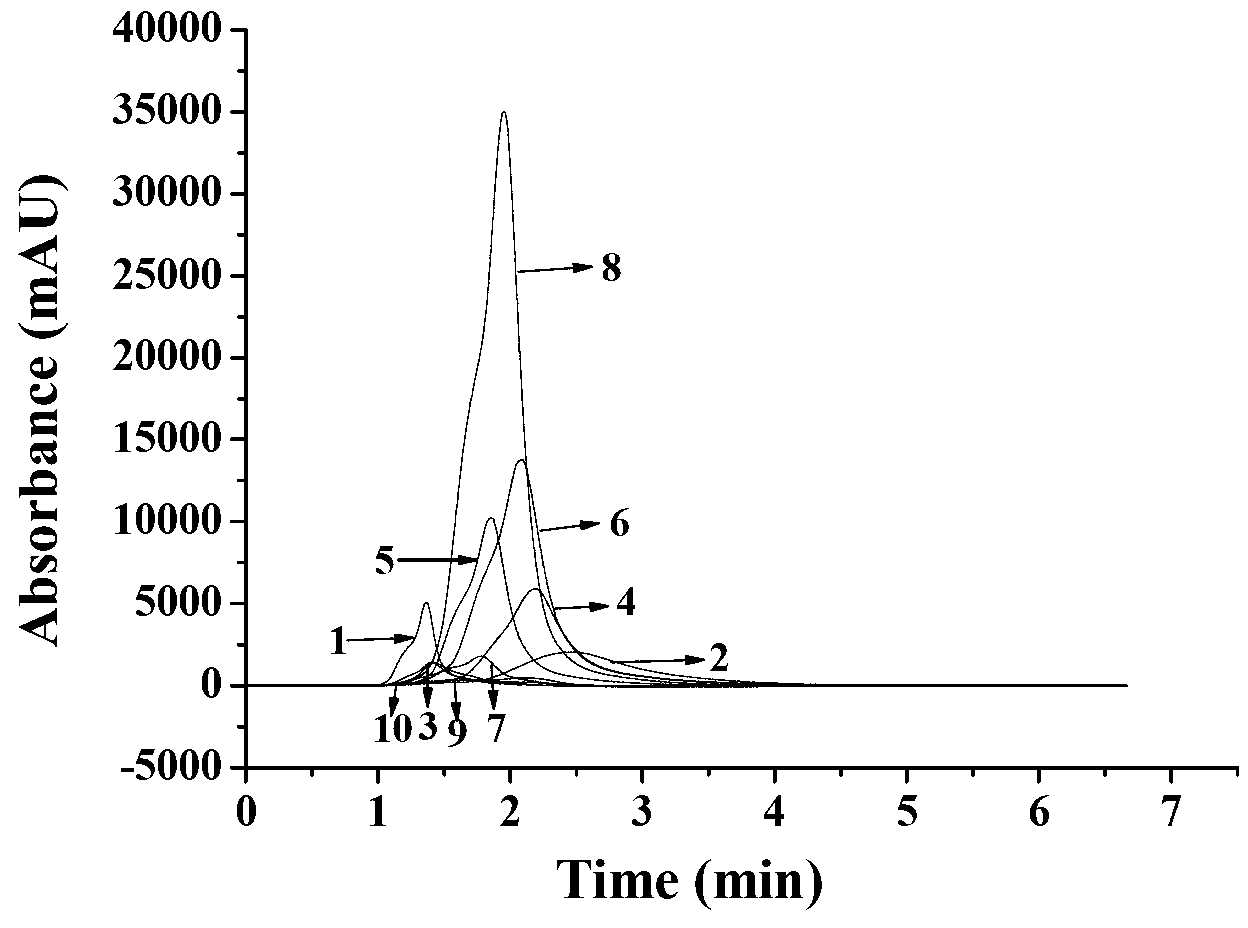

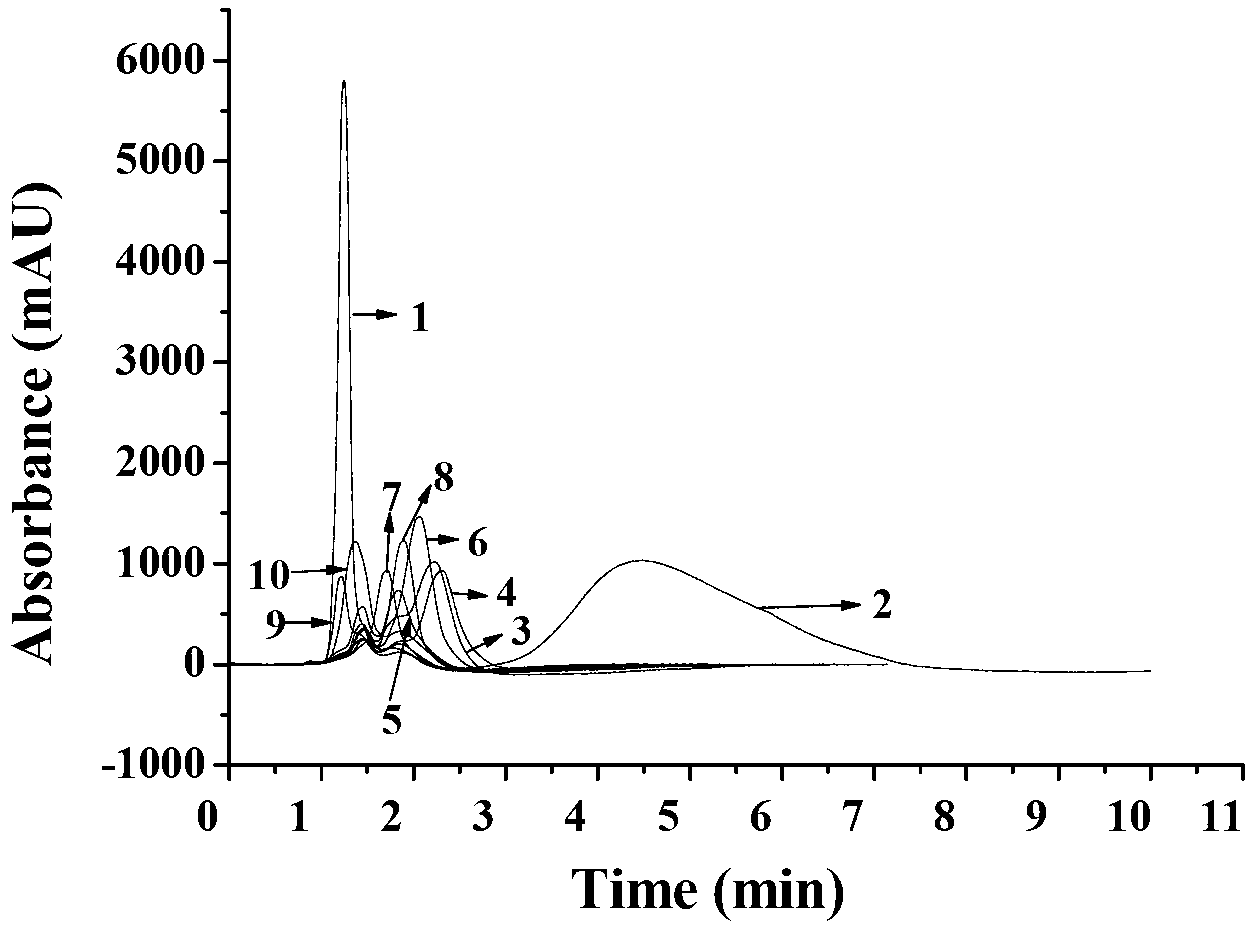

[0029] The chromatographic evaluation is the same as the investigation of the imprinted column in Example 1, that is, under the same mobile phase conditions, by measuring the retention time t of epigallocatechin gallate and its analog...

Embodiment 3

[0033] Preparation of epigallocatechin gallate imprinted monolithic column by in situ polymerization:

[0034] a. According to the mass number of the integrated epigallocatechin gallate imprinted column synthesized in a stainless steel column, accurately weigh the template molecule as epigallocatechin gallate 5.60%, and the functional monomer as acrylamide 5.1% , The crosslinking agent is ethylene glycol dimethacrylate 72.62%, the porogen is 5.28% of polystyrene dissolved in tetrahydrofuran solution (concentration 40mg / ml), and then 10.5% of isooctane is added, and the initiator is azo Mix 0.90% diisobutyronitrile, put it into a sonicator, sonicate for 20 minutes to make it homogeneous and clear, then transfer it to a clean stainless steel column (100×4.6mm I.D.), degas it for 15 minutes, and put the stainless steel tube Seal both ends of the column, and react in a constant temperature water bath at a temperature of 60°C for 24 hours;

[0035] b. Removal of template molecules...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com