Patents

Literature

40 results about "Ethyl gallate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

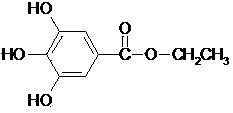

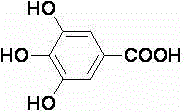

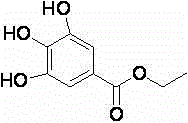

Ethyl gallate is a food additive with E number E313. It is the ethyl ester of gallic acid. Ethyl gallate is added to food as an antioxidant. Though found naturally in a variety of plant sources including walnuts Terminalia myriocarpa or chebulic myrobolan (Terminalia chebula), ethyl gallate is produced from gallic acid and ethanol. It can be found in wine.

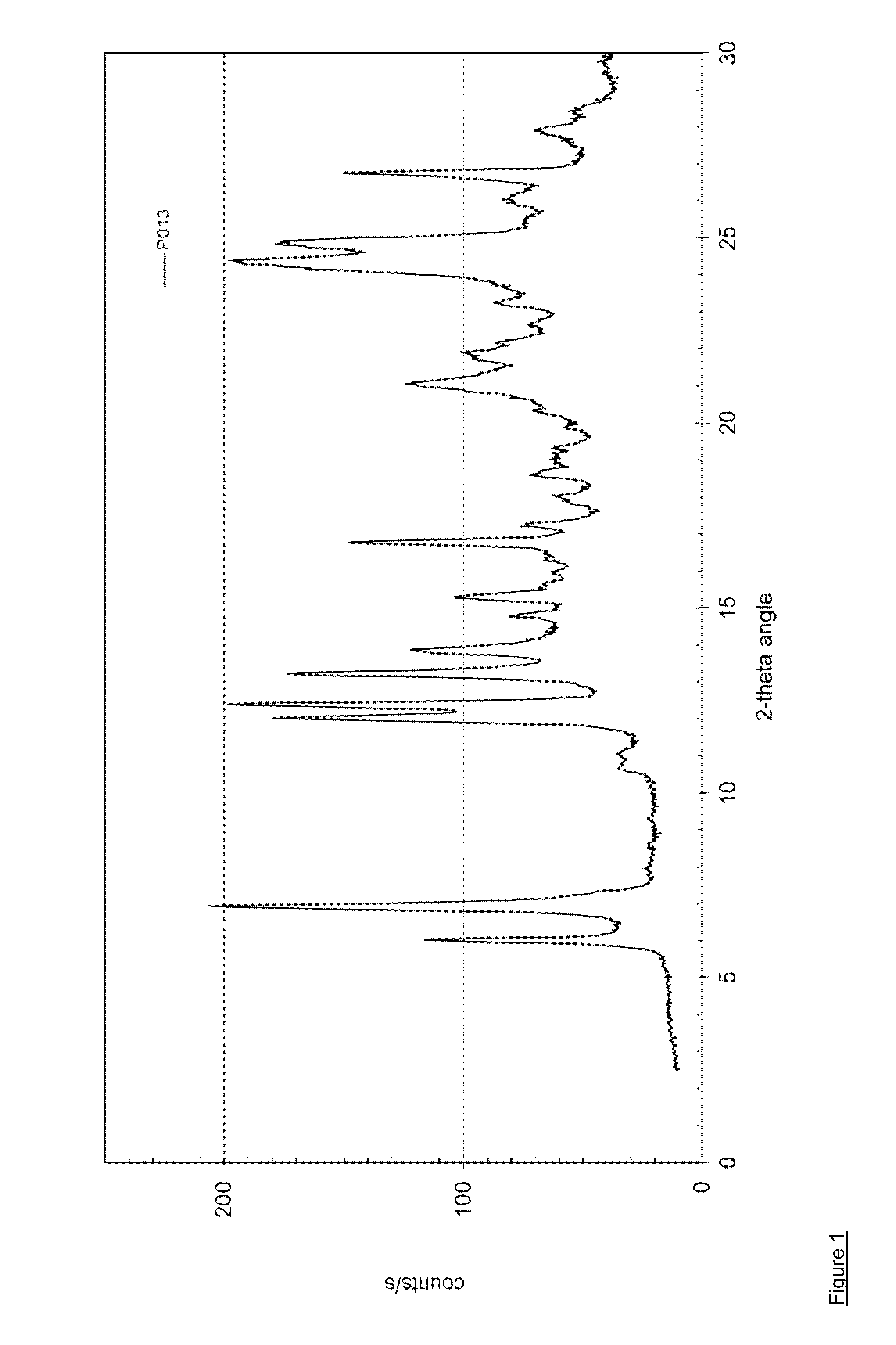

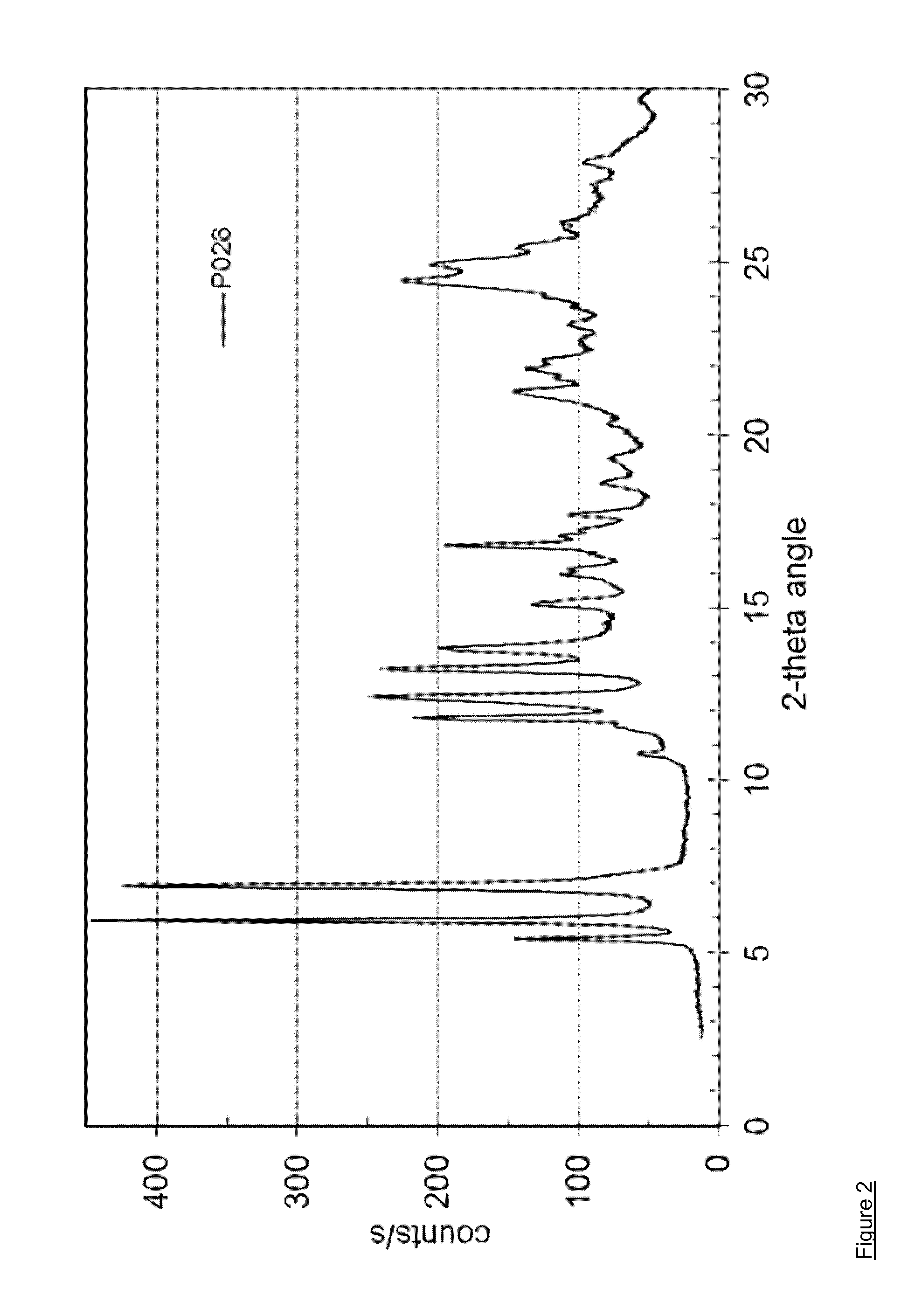

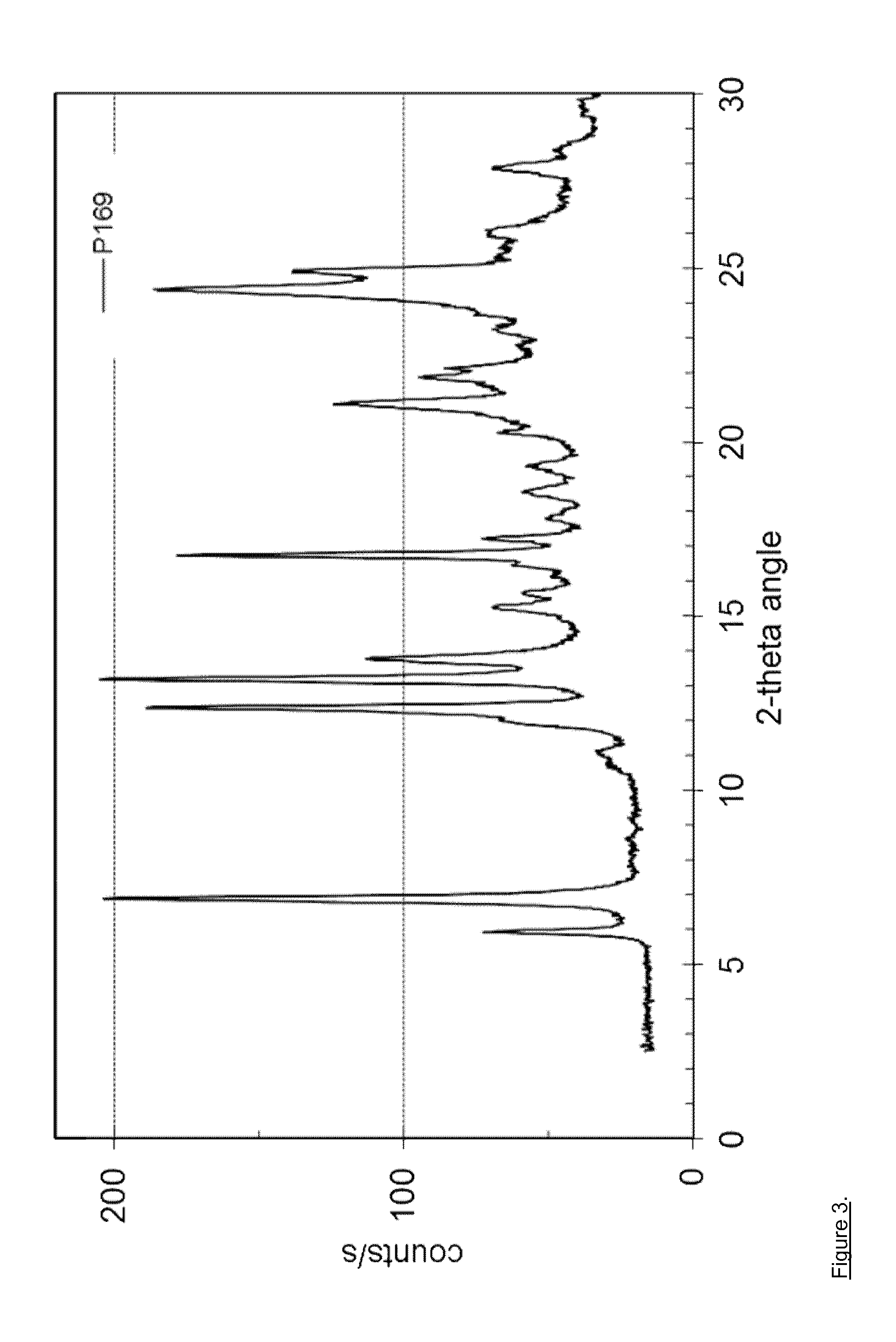

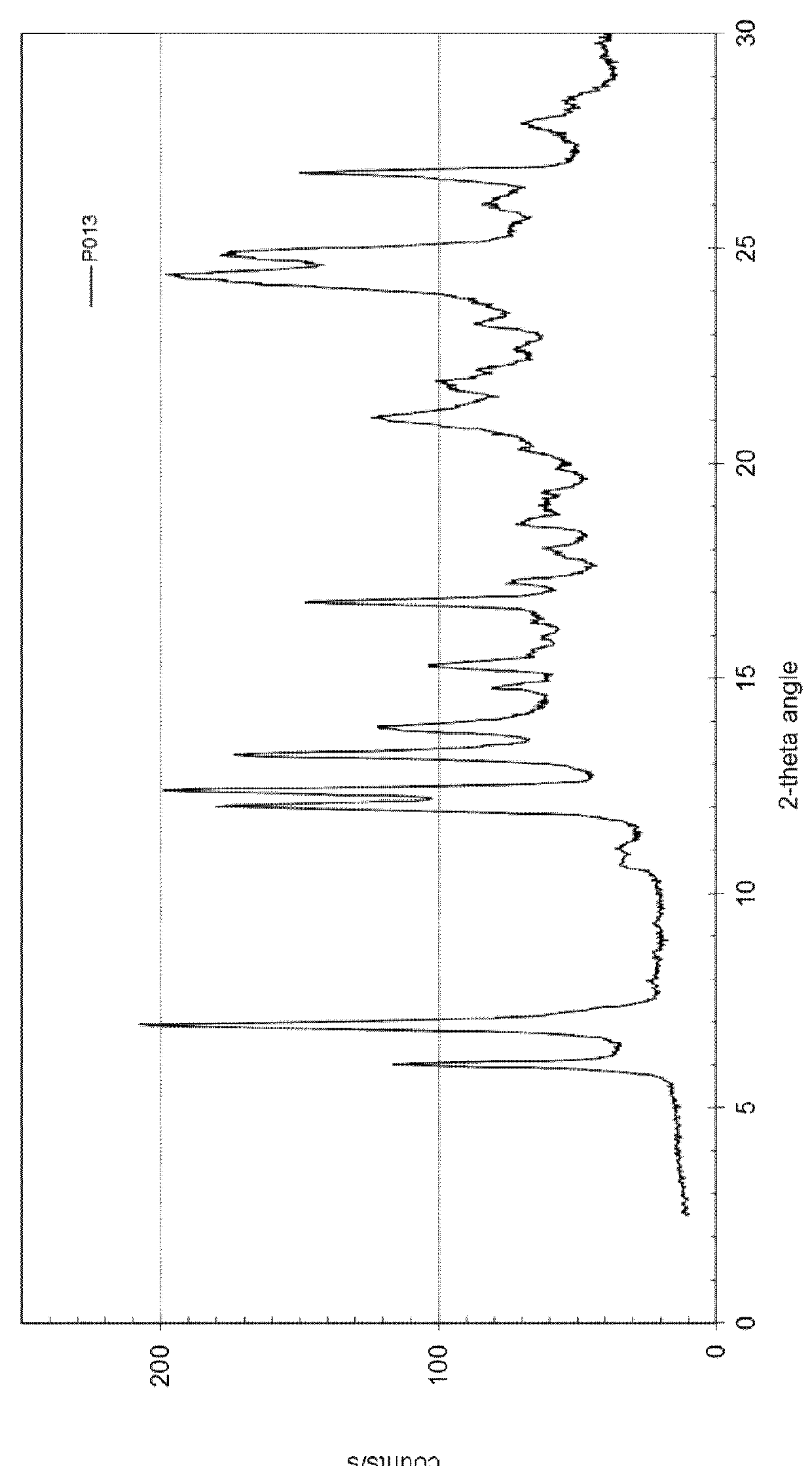

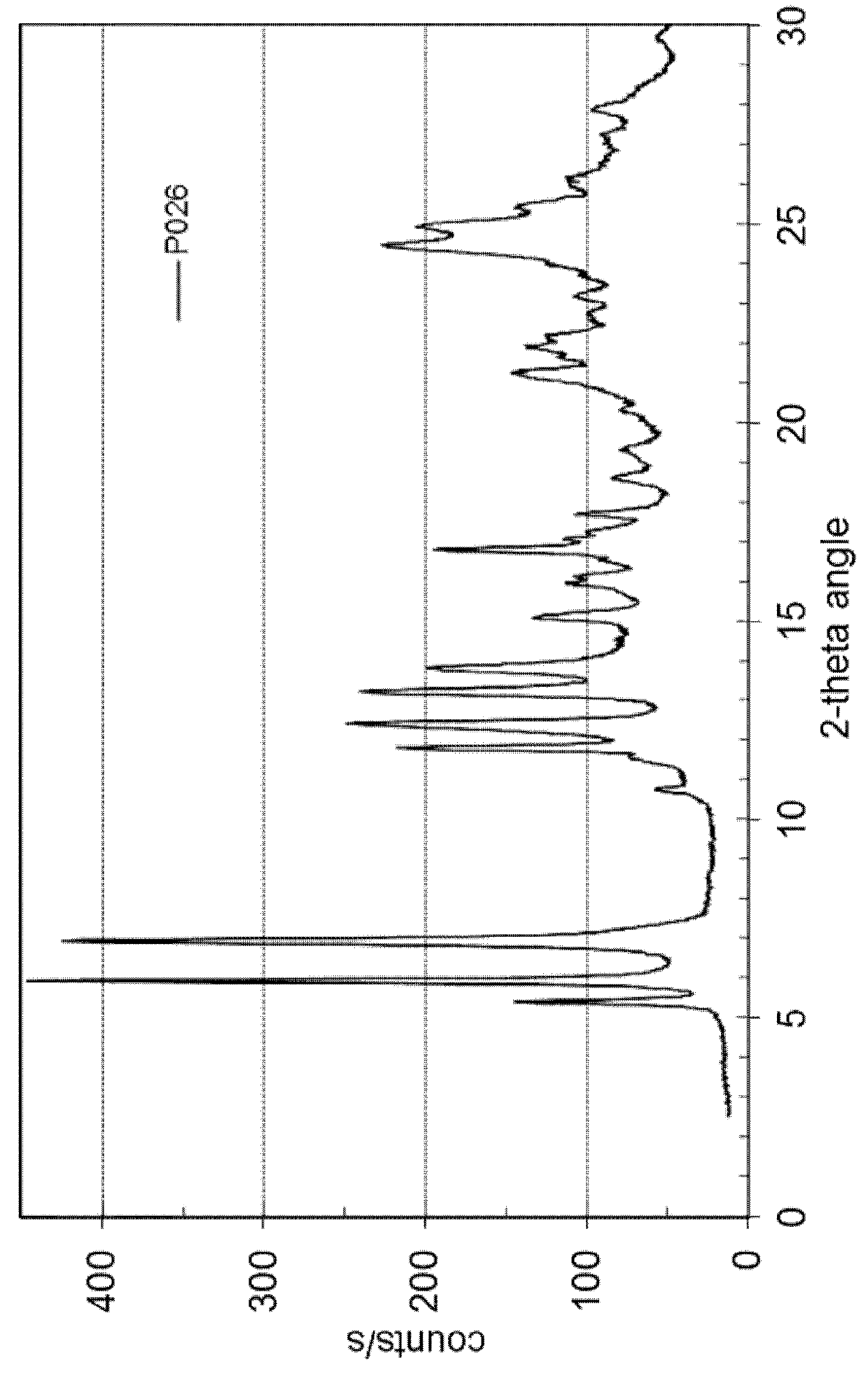

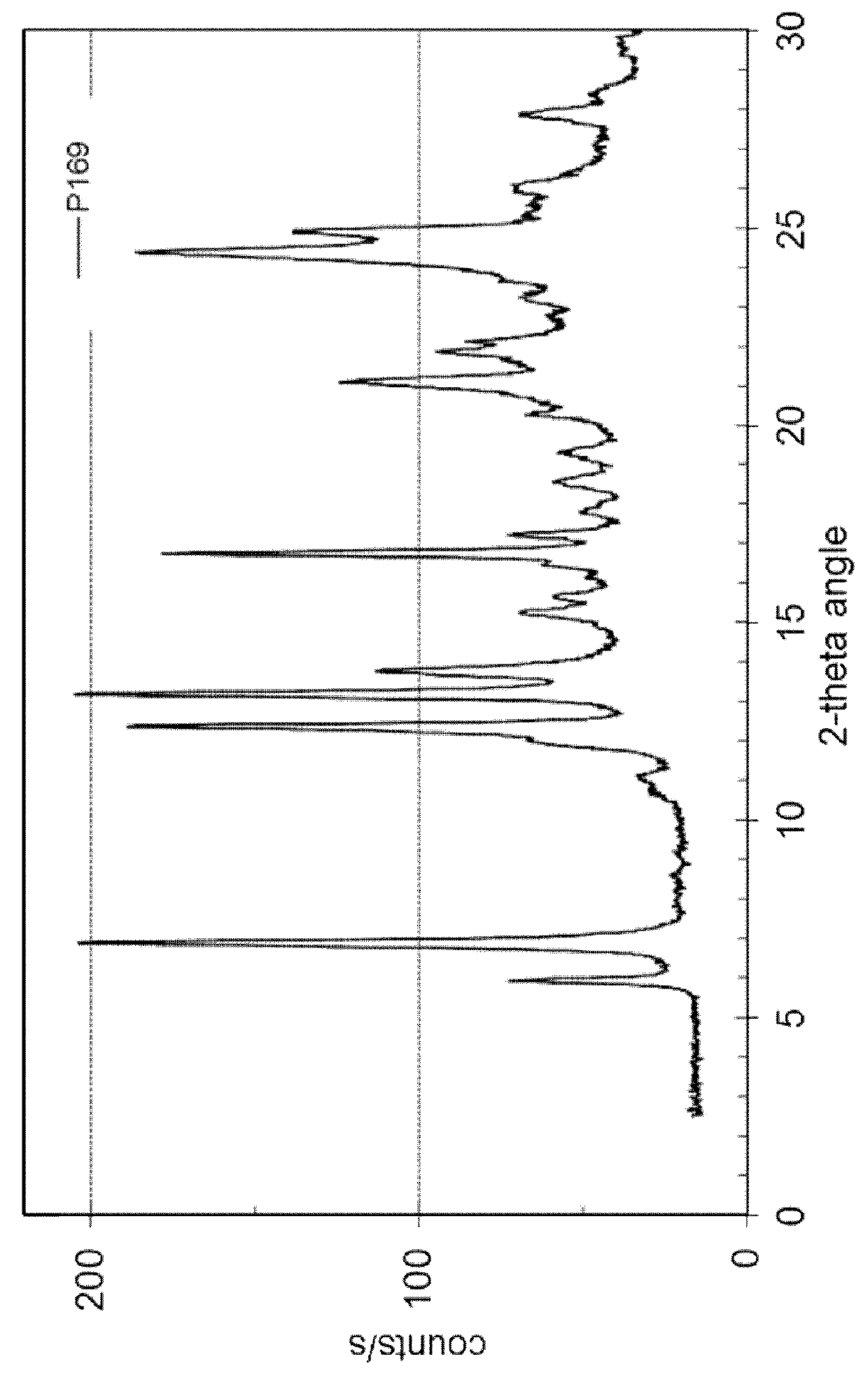

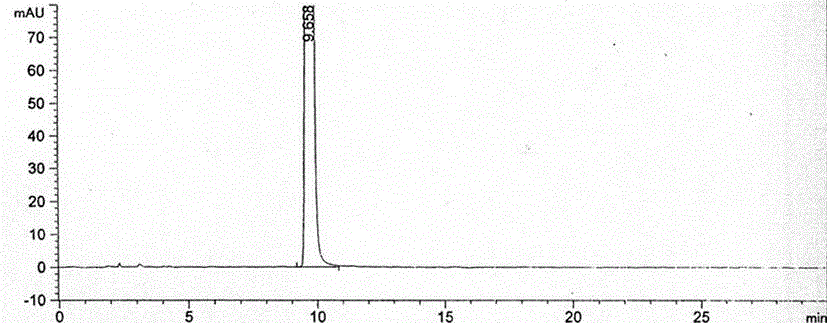

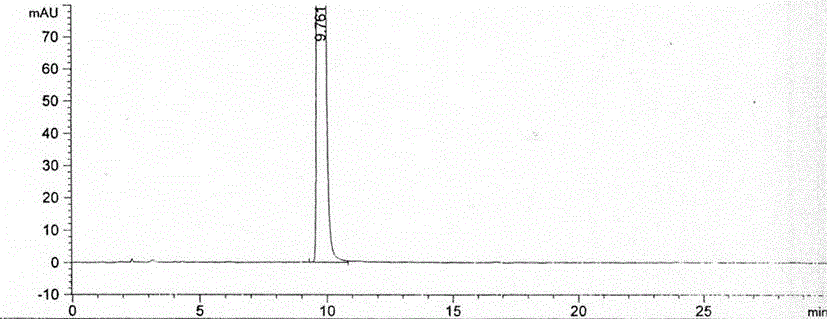

Multicomponent crystals comprising dasatinib and selected co-crystal formers

InactiveUS20150133463A1Improved profileImprove efficiencyOrganic active ingredientsOrganic chemistry methodsMentholEthyl maltol

Provided are a multicomponent crystalline system (co-crystal), use thereof, as well as a process for obtaining the same. The said multicomponent crystalline system (co-crystal) comprises Dasatinib and a second compound selected from methyM-hydrobenzoate, nicotinamide, ethyl gallate, methyl gallate, propyl gallate, ethyl maltol, vanillin, menthol, or (1R,2S,5R)-(−)-menthol.

Owner:BASF AG

Multicomponent crystals comprising dasatinib and selected co-crystal formers

InactiveUS9340536B2Improved profileImprove efficiencyOrganic active ingredientsOrganic chemistry methodsMentholDasatinib

Provided are a multicomponent crystalline system (co-crystal), use thereof, as well as a process for obtaining the same. The said multicomponent crystalline system (co-crystal) comprises Dasatinib and a second compound selected from methyM-hydrobenzoate, nicotinamide, ethyl gallate, methyl gallate, propyl gallate, ethyl maltol, vanillin, menthol, or (1R,2S,5R)-(−)-menthol.

Owner:BASF SE

Method for preparing nitisinone

ActiveCN102976948ALow toxicityLittle side effectsOrganic chemistryOrganic compound preparationBenzoic acidAluminium chloride

The invention discloses a method for preparing nitisinone, comprising the following steps of: preparing 2-nitryl-4-trifluoromethyl-benzoyl chloride from 2-nitryl-4-trifluoromethyl-benzoic acid and thionyl chloride as raw materials; adopting 2-nitryl-4-trifluoromethyl benzoyl chloride, 1,3-cyclohexanedione, ethyl gallate and anhydrous sodium carbonate as raw materials to react; layering, extracting, washing, drying and filtering in sequence; adding triethylamine and aluminum trichloride into the obtained filtrate for reaction; adding hydrochloric acid into the solution of reaction; standing for layering, washing by water, decolorizing and filtering in sequence to obtain the crude nitisinone; and recrystallizing and refining the crude nitisinone by ethyl acetate to obtain the product which is the nitisinone. Because the ethyl acetate is used as a solvent, the aluminum trichloride is used as a catalyst, and the anhydrous sodium carbonate is used as an acid binding agent, the toxicity of the product which is the nitisinone is reduced greatly, the side effect is reduced significantly, and high product purity of more than 99.5% is achieved.

Owner:郑州大明药物科技有限公司

Emblic cotyledon preparation with pulmonary emphysema against function

InactiveCN101156887AHighlight substantive featuresSignificant progressRespiratory disorderPlant ingredientsGallic acid esterEthyl ester

The invention relates to Chinese medicine preparation, in particular to Chinese medicine preparation produced by using emblic leafflower fruit leaves as the raw material to produce extractive, and then using the extractive as the raw material. The result of an animal test shows that the extractive of the emblic leafflower fruit leaves and the Chinese medicine preparation thereof has the function of emphysema resistance; the preparation for emphysema resistance has the main components of gallic acid, gallicin, gallic acid ethyl ester, and propyl gallate.

Owner:广西中医学院

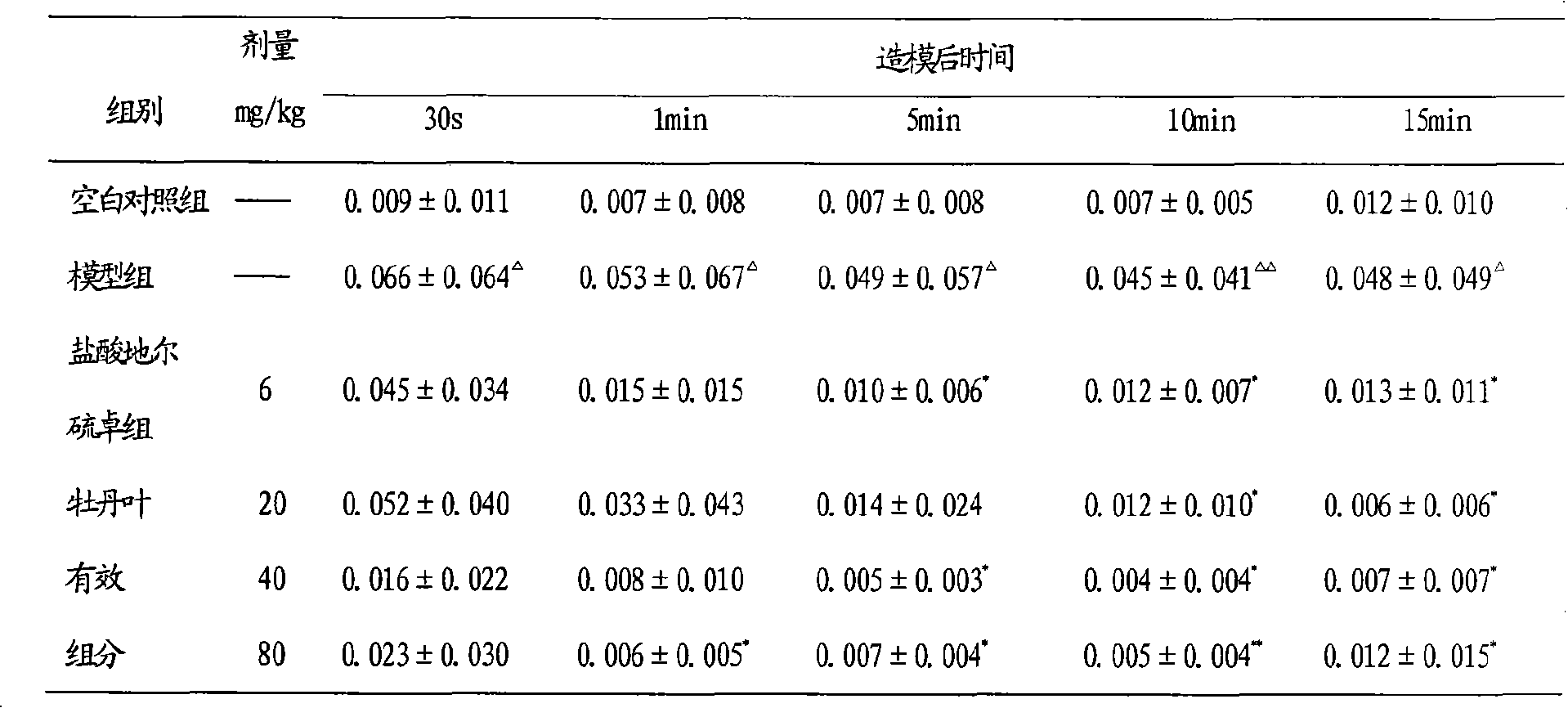

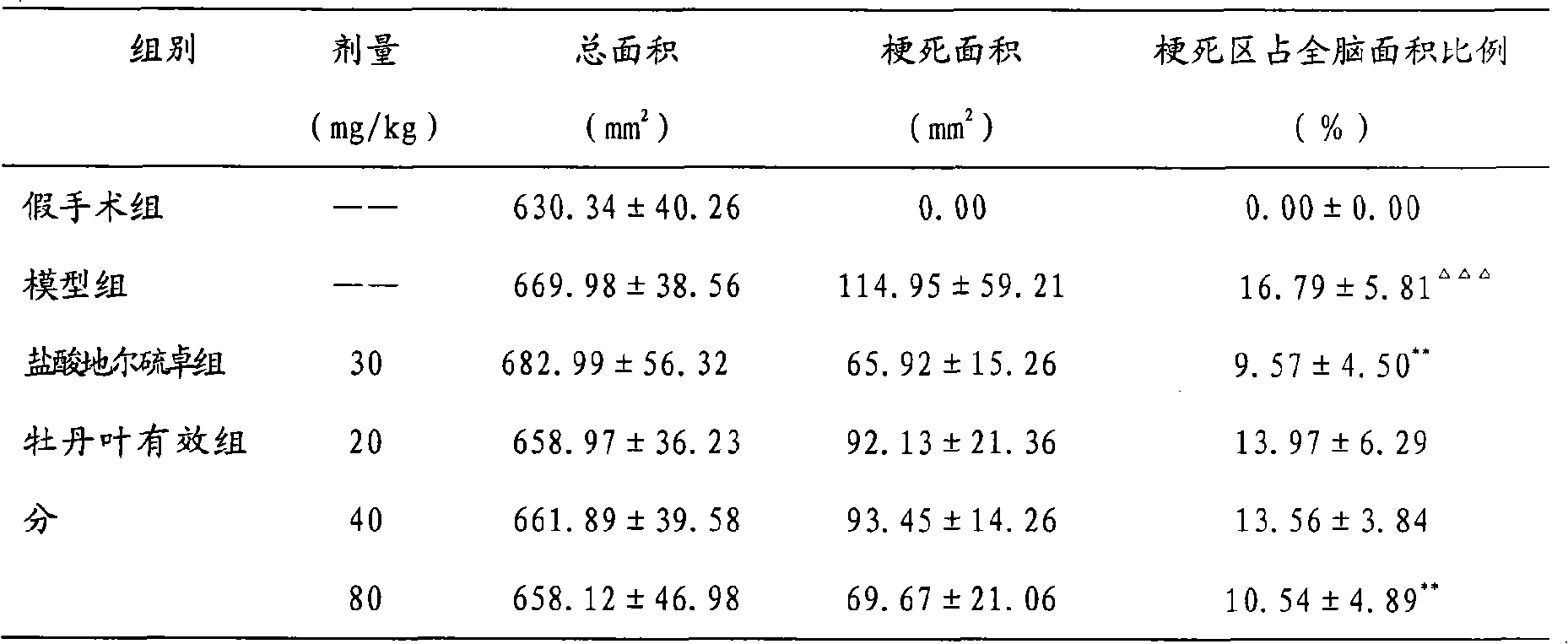

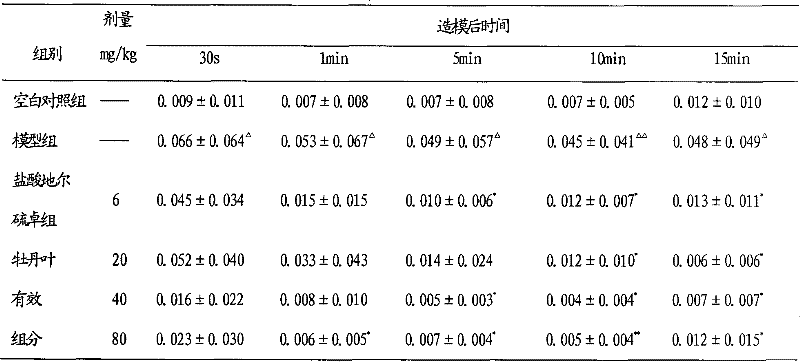

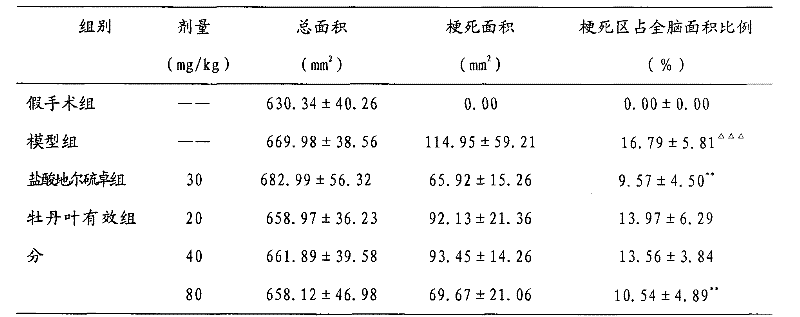

Effective components of peony leaves as well as preparation method and application thereof

ActiveCN101574410ASimple preparation processLow costPharmaceutical delivery mechanismCardiovascular disorderDiseaseGallic acid ester

The invention relates to effective components of peony leaves, which are separated and obtained from the peony leaves and mainly comprise gallic acid and progallin A, wherein the content of the gallic acid is 35-70 percent, and the content of the progallin A is 15-30 percent. The invention also provides a preparation method of the effective components of the peony leaves by adopting macroporous resin purification and provides a medicine preparation of the effective components. The animal experiment result shows that the effective components can effectively prevent and treat cardiovascular and cerebrovascular diseases and especially have the functions of preventing and treating the coronary heart disease and the cerebral ischemia disease.

Owner:北大世佳科技开发有限公司

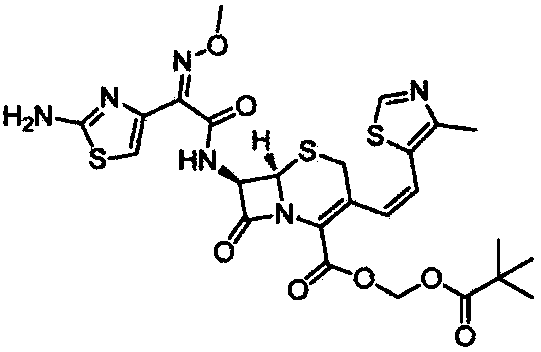

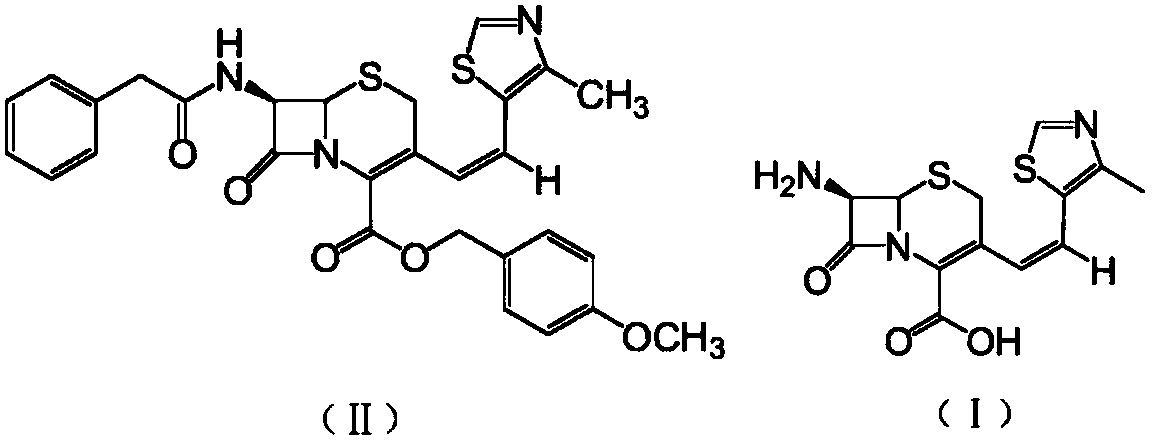

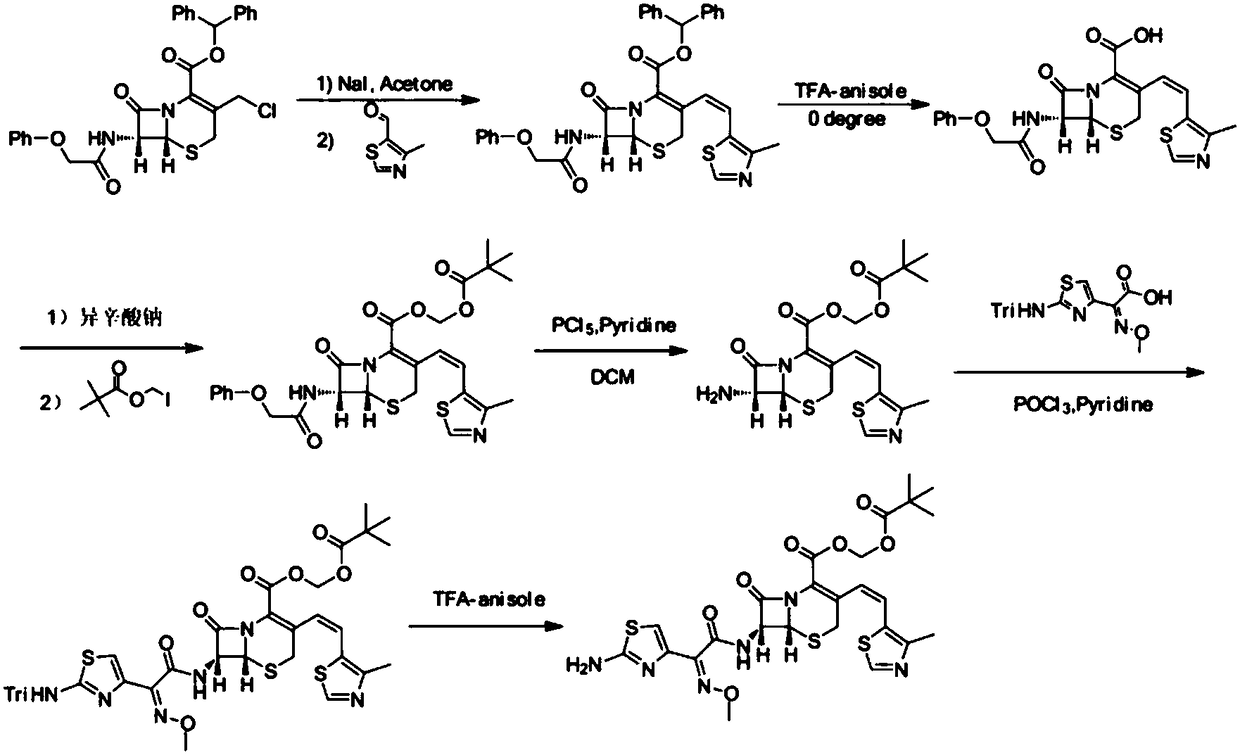

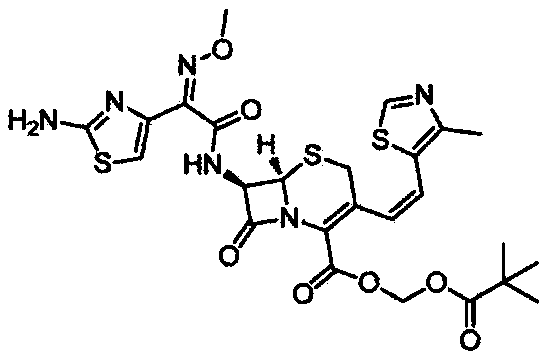

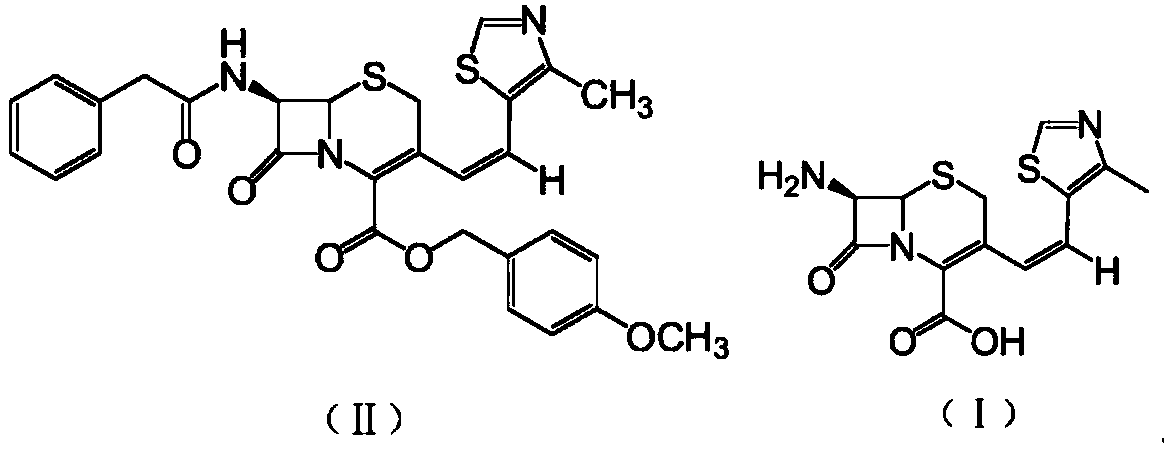

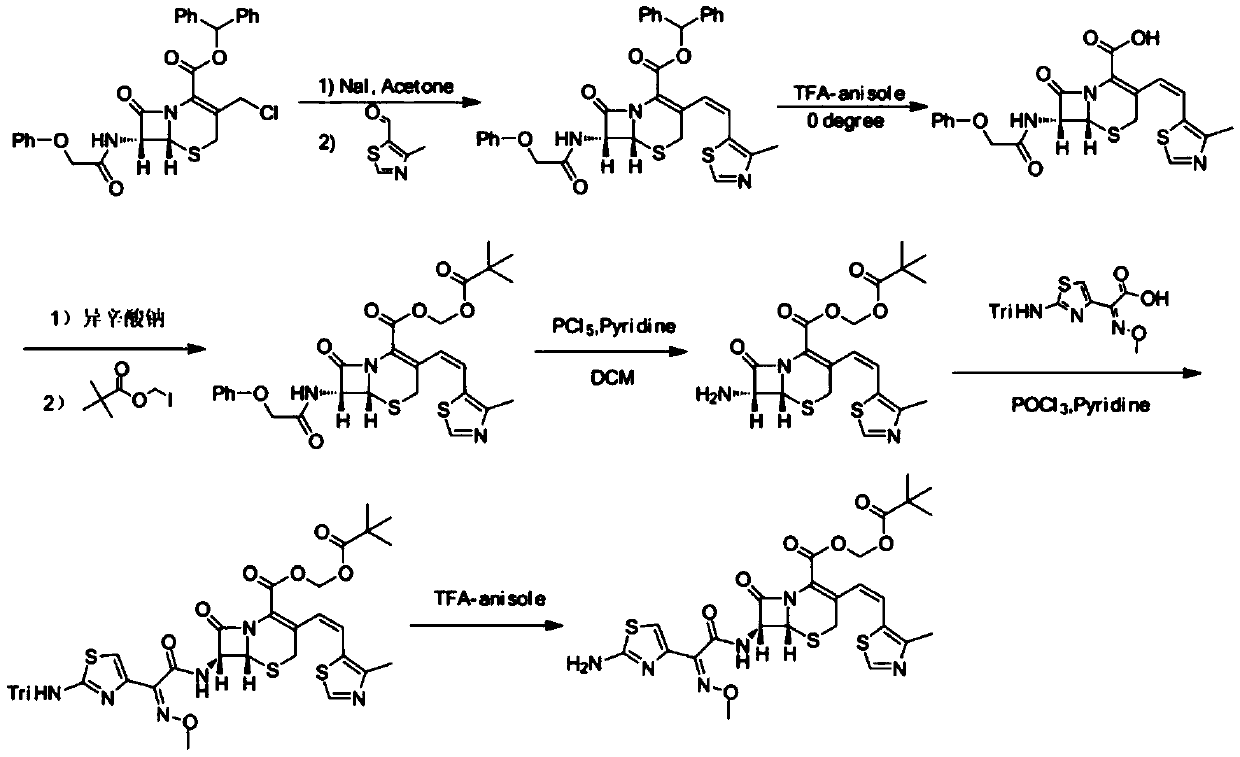

Preparation method of Cefditoren Pivoxil

The invention relates to a preparation method of Cefditoren Pivoxil. The preparation method comprises steps as follows: 7-ACA (3-acetyloxymethyl-5-thio-7-amino-8-oxy-1-nitrogen heterobicyclic octyl-2-ene-2 carboxylic acid) is taken as a starting raw material and is subjected to iodination and Wittig reaction after silanization protection, and a Cefditoren parent nucleus 7-ATCA (7-amino-3-[(Z)-2-(4-methyl-5-thiazole) vinyl]-3-cephem-4-carboxylic acid) is generated; after amino protection of aminothiazole ethyl gallate, a compound 2 is produced from 7-ATCA under catalysis of AlMe3; the compound2 is subjected to an esterification reaction with iodomethyl pivalate under actions of a phase transfer catalyst and an acid adsorbent, the amino protection is removed, and a target product CefditorenPivoxil is obtained. According to the preparation method, reaction conditions are mild, product purity and yield are high, the process is stable, amplification is easy, and the method is applicable to industrial production.

Owner:SHANDONG YUXIN PHARMA CO LTD

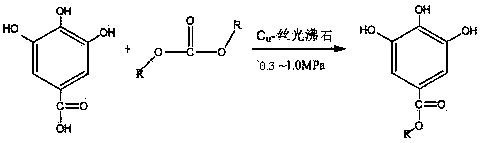

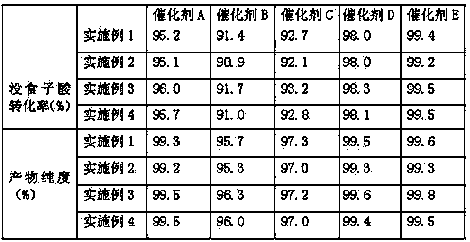

Method for synthesizing methyl (ethyl) gallate through catalysis of Cu-mordenite

ActiveCN103709039AHigh purityThe preparation process is simple and easy to obtainMolecular sieve catalystsOrganic compound preparationGallic acid esterMethyl carbonate

The invention relates to a method for synthesizing methyl (ethyl) gallate through catalysis of Cu-mordenite. The method comprises the step: by taking gallic acid and dimethyl carbonate or diethyl carbonate as raw materials and Cu-mordenite as a catalyst, performing transesterification reaction under pressurization to obtain methyl gallate or ethyl gallate. As the green and environment-friendly dimethyl carbonate or diethyl carbonate are a methylating (ethylating) agent, the method is low in cost and environment-friendly, the yield of the synthesized technical products can achieve more than 98%, and the purity of the ethyl gallate product is greater than 99%.

Owner:南京龙源天然多酚合成厂 +1

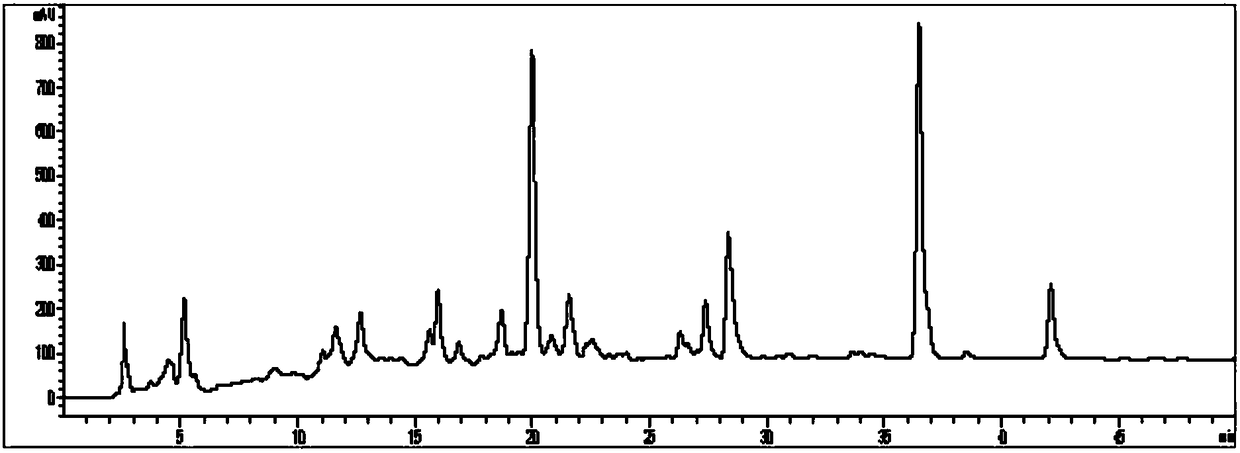

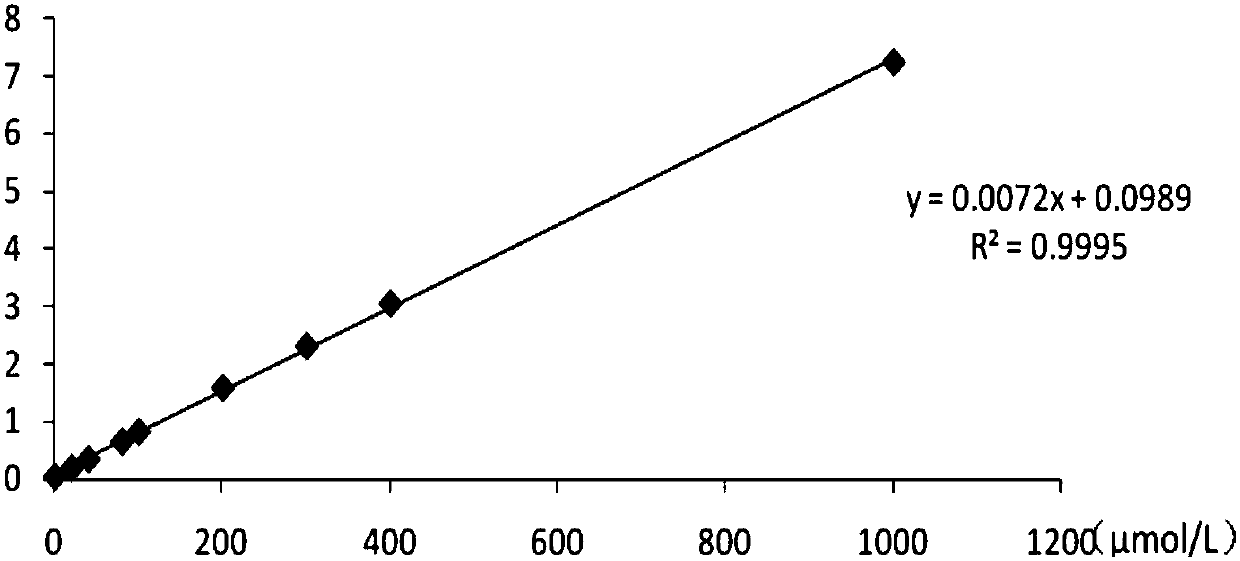

Method for detecting trace lipid-soluble tea polyphenol in vegetable oil

ActiveCN102128827AThe experimental equipment is simpleLow costMaterial analysis by observing effect on chemical indicatorGallic acid esterVegetable oil

The invention discloses a method for detecting trace lipid-soluble tea polyphenol in vegetable oil, which comprises the following steps of: making a gallic acid ethyl ester standard curve, analyzing effective ingredient content of the lipid-soluble tea polyphenol, making a lipid-soluble tea polyphenol labeled curve, then detecting the absorbance of an oil sample to be detected, and substituting the detected value of the absorbance into the labeled curve to obtain the lipid-soluble tea polyphenol content of the oil sample. The method has the characteristics of simple operation, low cost, good repeatability and high accuracy.

Owner:SHANDONG LUHUA GROUP

Extraction method of ethyl gallate in peony leaves and new application thereof

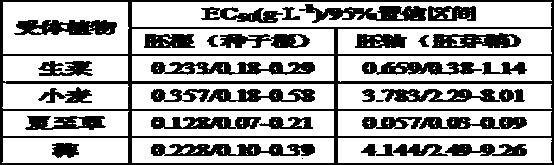

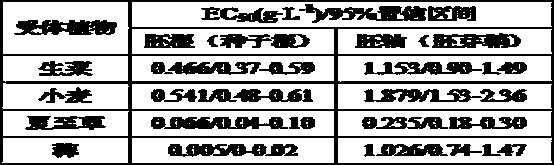

InactiveCN103450023ACarboxylic acid esters separation/purificationHerbicides and algicidesEthyl esterEthyl acetate

The invention relates to the field of chemistry and agriculture, and particularly provides an extraction method of ethyl gallate in peony. The method comprises the following steps: extracting the plant dry powder of peony leaves by use of ethanol, petroleum ether and ethyl acetate; performing gradient elution on the ethyl acetate extract through silica gel column chromatography by use of petroleum ether in combination with acetone and acetone in combination with methanol respectively to obtain 8 fractions; and performing gradient elution on the M5 fraction with higher activity by use of petroleum ether in combination with acetone to obtain ethyl gallate. The invention further provides a new application of the ethyl gallate in weeding.

Owner:QINGDAO AGRI UNIV

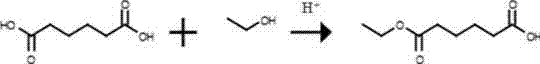

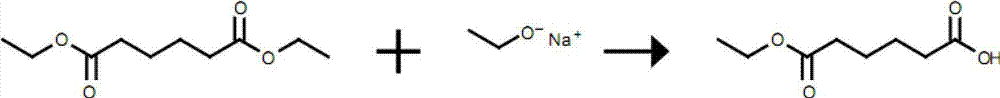

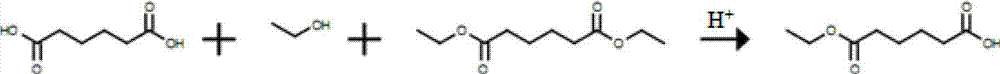

Synthetic method of monomethyl adipate

InactiveCN102898306AReflect environmental protectionHigh yieldOrganic compound preparationCarboxylic acid esters preparationDistillationAdipic acid

The invention discloses a synthetic method of monomethyl adipate, belonging to the technical field of organic chemistry and drug synthesis. The synthetic method disclosed herein comprises the following steps: firstly successively immersing macroporous cation exchange resin in acid solution, alkali liquor and acid solution, then washing the immersed macroporous cation exchange resin with water until the pH value of the resin is neutral, then filtering and removing the moisture attached to the surface of the macroporous cation exchange resin to obtain a pretreated resin; adding adipic acid and the pretreated resin in toluene, and conducting esterification with adding organic ethyl gallate dropwisely, filtering after reaction finished to separate the resin, filtering the toluene liquid after the toluene liquid is cooled to leach unreacted adipic acid, washing the monomethyl adipate toluene liquid, conducting reduced pressure condensation and recovering the solvent, and then conducting distillation to obtain the monomethyl adipate. According to the invention, the method has the advantages of high yield, convenient the post-treatment, no pollution, and reusability; and the resin can be directly reused, the solvent is recovered, thus the resource can be saved, and environmental protection property is achieved.

Owner:SUZHOU FUSHILAI PHARMA CO LTD

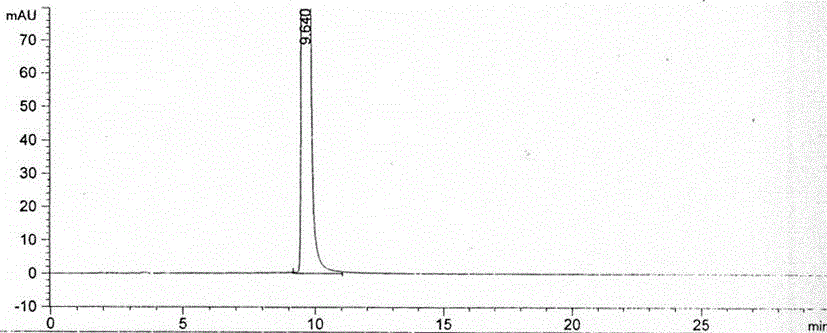

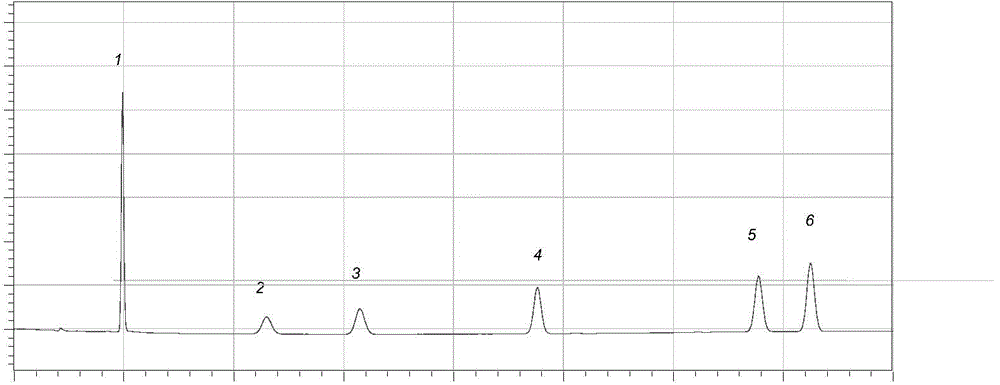

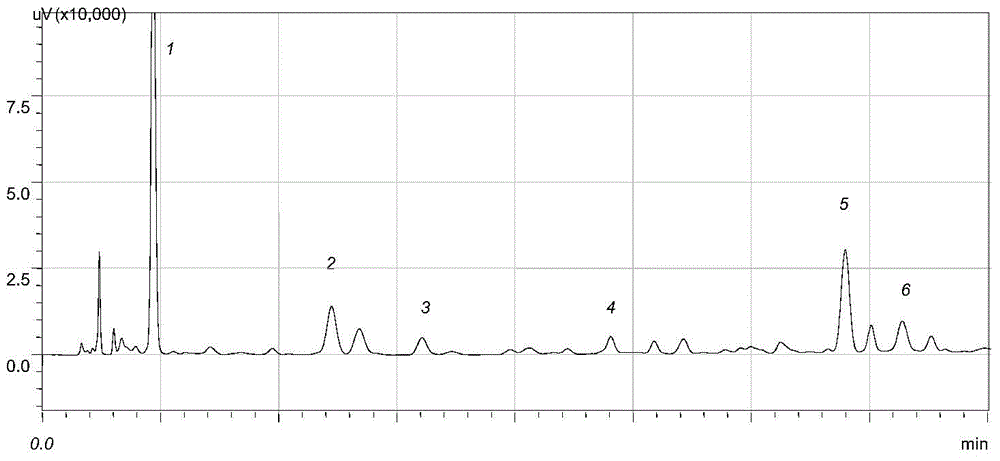

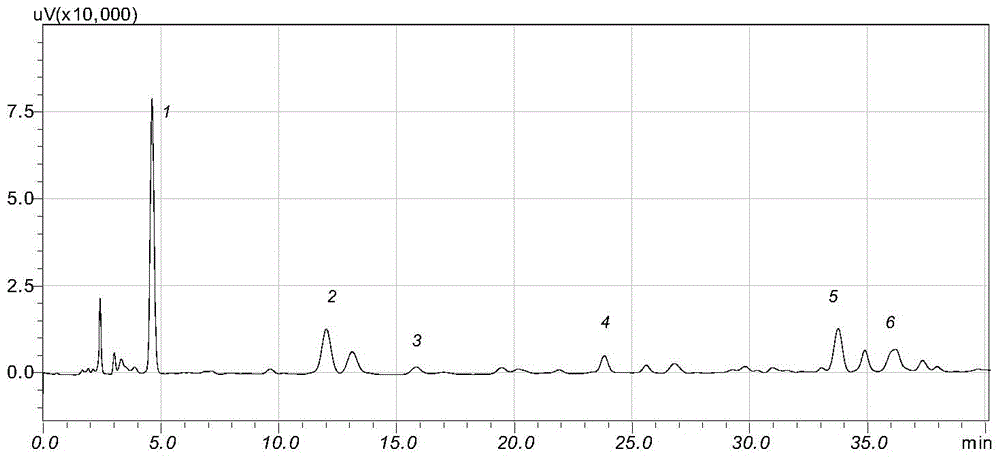

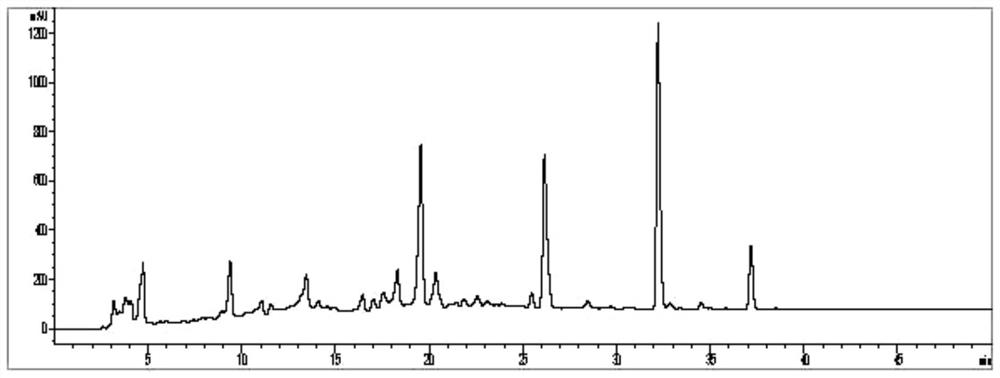

Determination method for multi-component content in Longan leaves

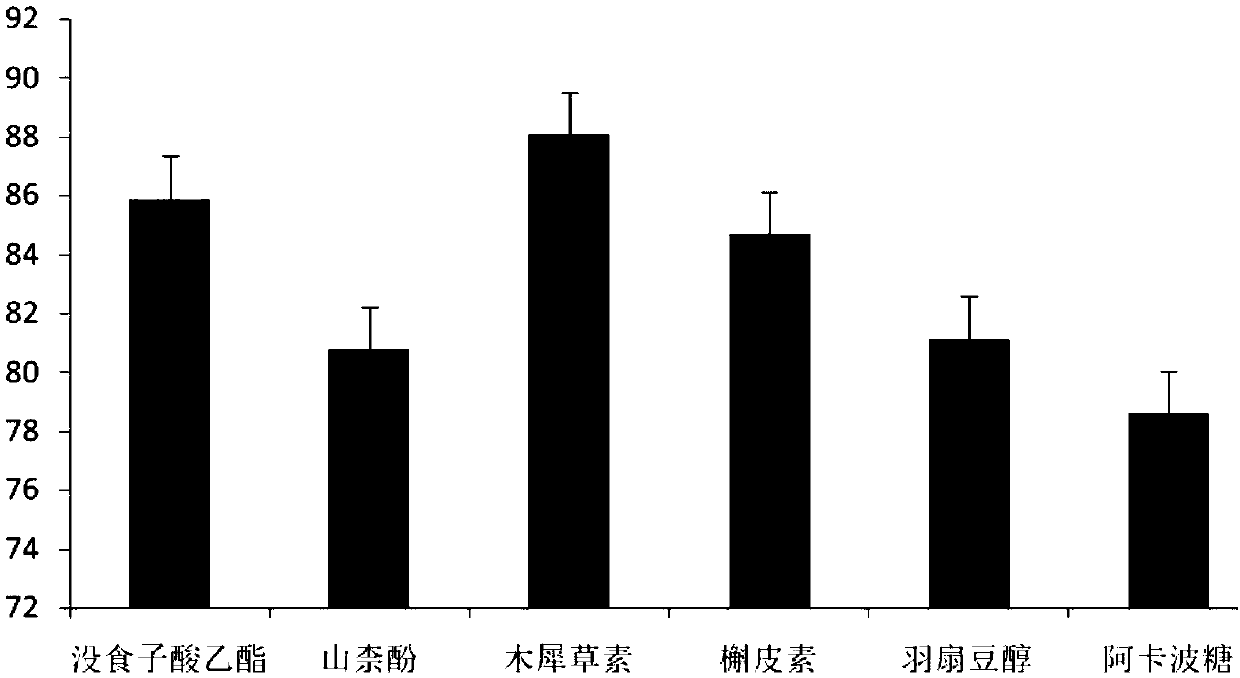

The invention discloses a determination method for multi-component content in Longan leaves. In the determination method, the high-performance liquid chromatography is used to determine the content ofethyl gallate, astragalin, quercetin, luteolin and kaempferol in the longan leaves simultaneously. The method has the advantages of high efficiency, accuracy, good resolution, repeatability and stability, simple and easy operation, and can effectively control the quality of the longan leaves.

Owner:GUANGXI UNIV OF CHINESE MEDICINE

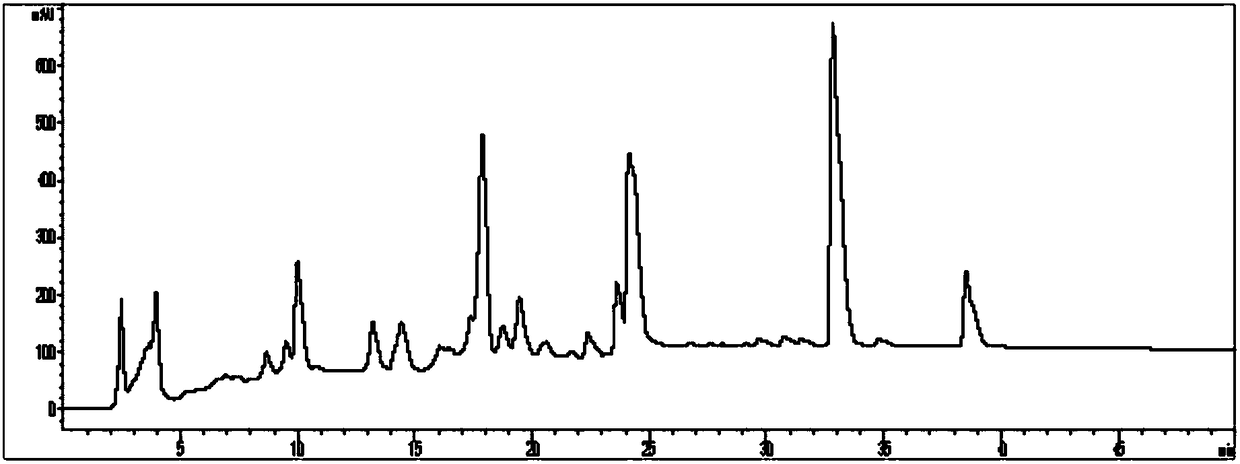

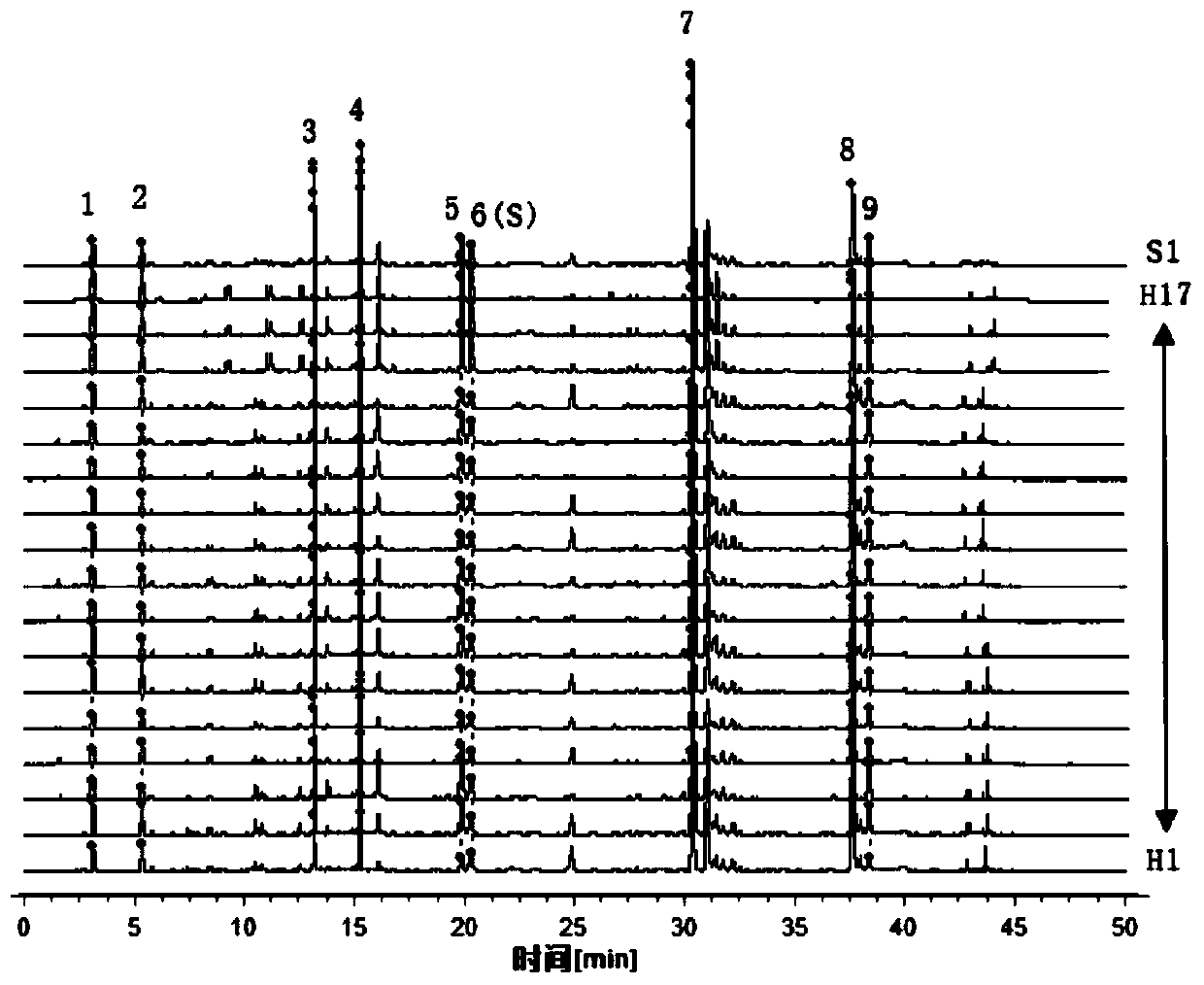

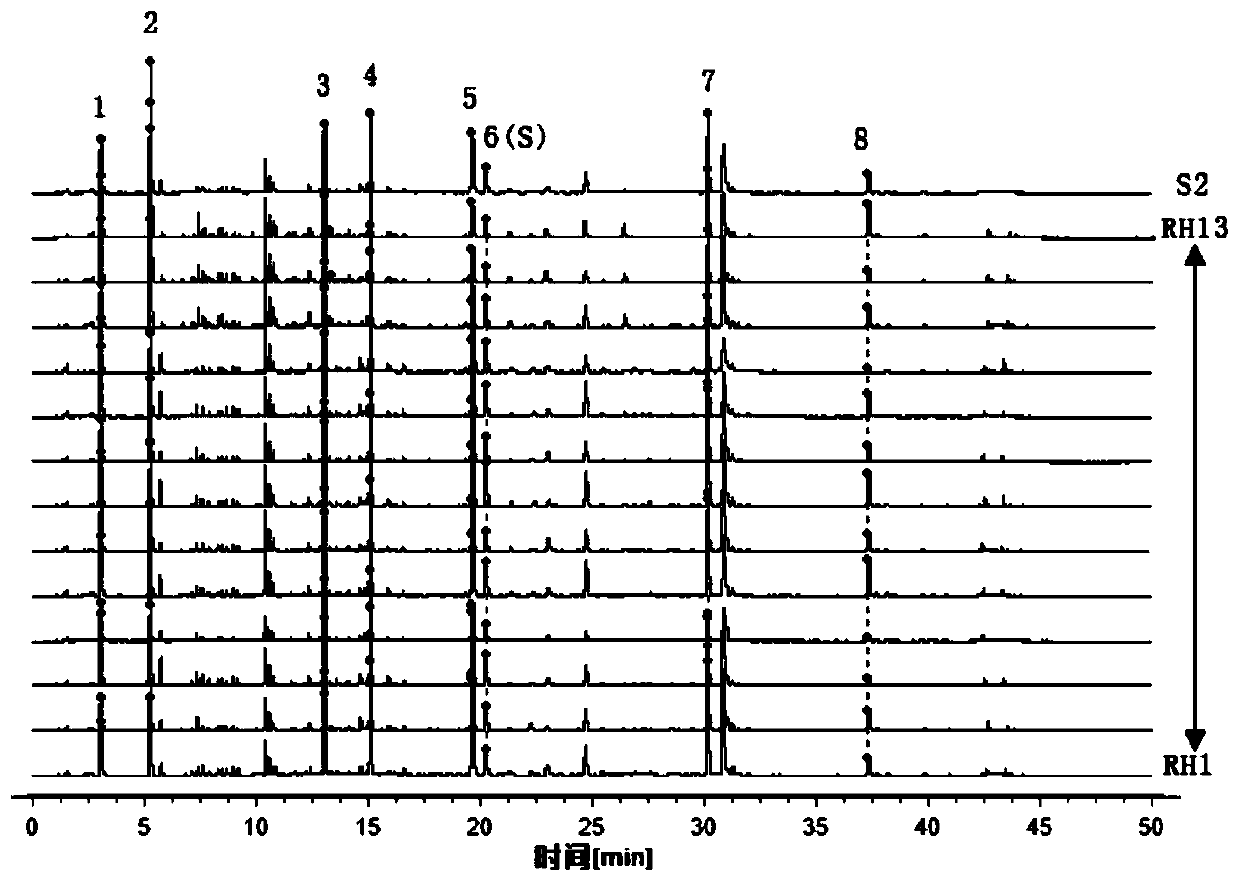

HPLC separate detection for polyphenols and rhodiola crenulata quality detection method

InactiveCN104569186AImprove practicalityImprove applicabilityComponent separationSalidrosideHplc method

The invention discloses an HPLC separate detection for polyphenols. Aiming at the defects of limited quantity of components, which can be simultaneously separated and detected, in a rhodiola crenulata medicinal material in the prior art, and poor comprehensive quality control effect on the rhodiola crenulata medicinal material, the invention provides a high performance liquid chromatography method for six polyphenol components comprising gallate, rhodioloside and the like, and application of the high performance liquid chromatography method in quality detection of the rhodiola crenulata medicinal material. A test article and / or a reference substance for the detection method disclosed by the invention comprise at least one of gallate, rhodioloside, butyl alcohol, catechinic acid, ethyl gallate and p-coumaric acid; the chromatographic conditions are that a C18 chromatographic column is adopted, and the column temperature is 25 DEG C; the mobile phase is a mixed solution of acetonitrile and 0.04% phosphoric acid solution; the volume percent of the acetonitrile is 7%-20%; and gradient elution is carried out. The invention further provides a rhodiola crenulata quality detection method. The HPLC method in the detection method disclosed by the invention has conventional chromatographic conditions; special treatment on samples is not required; and the practicability and the applicability are high.

Owner:西藏藏医药大学

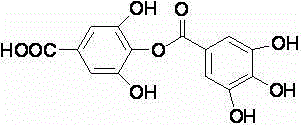

Application of liquidambar formosana hance fruit tannin monomer

InactiveCN102743367AOrganic active ingredientsNervous disorderGallic acid esterAmine oxidase inhibitors

The invention relates to applications of liquidambar formosana hance fruit tannin monomer. The monomer comprises the components of gallic acid, ethyl gallate, p-digalloyl acid, and ethyl-p-digallate. The invention relates to the application of the monomer in preparing a monoamine oxidase inhibitor. The invention is characterized in that the invention relates to the applications of gallic acid, ethyl gallate, p-digalloyl acid, and ethyl-p-digallate in preparing medicines used for treating depression and Parkinson's disease.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

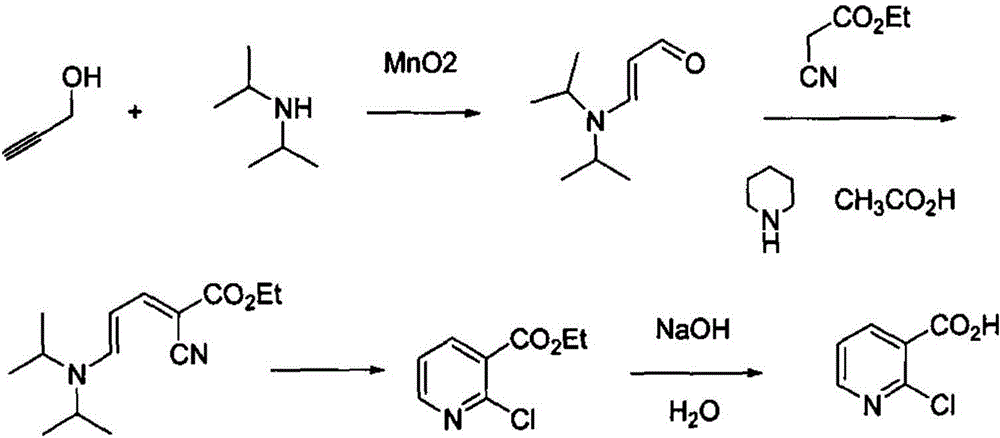

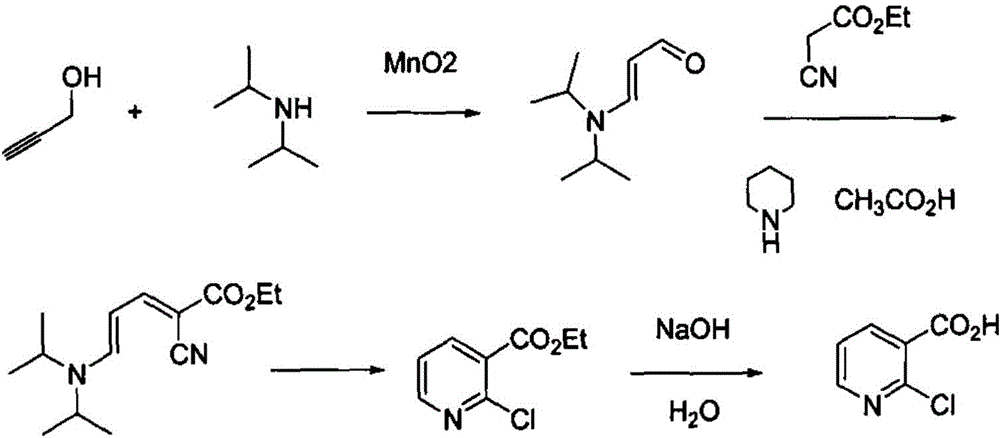

Method for producing 2-chloro nicotinic acid

The invention relates to a method for producing 2-chloro nicotinic acid. Propiolic alcohol and diisopropylamine are catalyzed and oxidized to obtain diisopropylamine acrolein. Then Konevenagel reaction is carried out to the diisopropylamine acrolein and ethyl cyanacetate to generate 2-cyan-5-diisopropylamine-2, 4-pentadiene ethyl gallate. Dried hydrogen chloride is let in, and the obtained ethyl 2-chloronicotinate is acidized to obtain 2-chloro nicotinic acid after basic hydrolysis. Compared with the prior art, the method for producing the 2-chloro nicotinic acid employs raw materials easy to purchase, has no rigor condition in the process, and is friendly to environment and suitable for industrialization production.

Owner:SHANGHAI TAIHE INT TRADE CO LTD +1

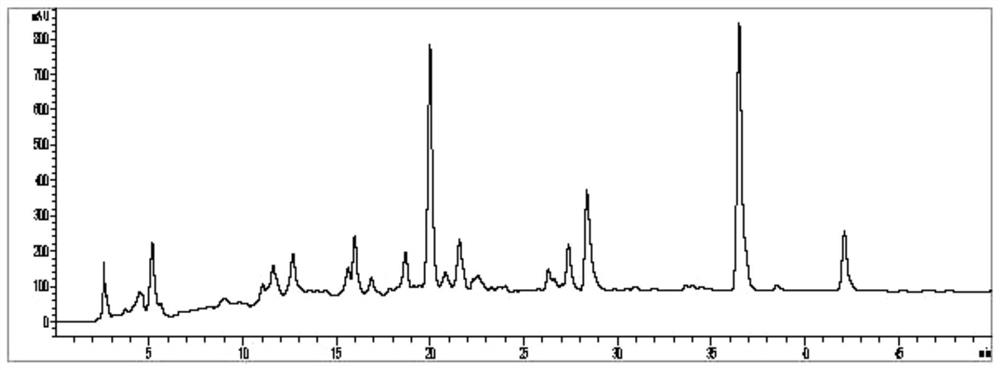

Construction method and application of medicine Terminalia fruit and Terminalia chebula Retz.var.tomentella Kurt. medicinal material specific chromatogram

ActiveCN111272904AFully respond to characteristic peak informationComprehensive evaluationComponent separationBiotechnologyMedicinal herbs

The invention relates to a construction method and application of a medicine Terminalia fruit and Terminalia chebula Retz.var.tomentella Kurt. medicinal material characteristic spectrum. The construction method of the medicine Terminalia fruit medicinal material specific chromatogram comprises the following steps: preparing a reference substance solution by taking gallic acid, ethyl gallate, corilagin, Chebulagic acid, myrobalan acid and chebulic acid as reference substances; dissolving a medicine Terminalia fruit in a solvent, performing ultrasonic extraction, filtering an extracting solution, and taking subsequent filtrate to obtain a medicine Terminalia fruit test solution; respectively carrying out ultra-high performance liquid chromatography detection on the reference substance solution and the medicine Terminalia fruit test solution. Chromatographic conditions of the ultra-high performance liquid chromatography comprise that a mobile phase A is acetonitrile, a mobile phase B is aphosphoric acid aqueous solution with a volume fraction of 0.1-0.3%, and an elution mode is gradient elution. The invention provides a comprehensive, effective and rapid method for controlling and evaluating the quality of the medicine terminalia fruit (collectively referred to as myrobalan).

Owner:GUANGDONG YIFANG PHARMA

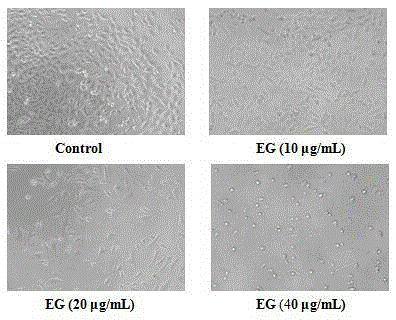

New application of ethyl gallate to osteosarcoma treatment

Functions of ethyl gallate are found by researchers one by one, but researches in the aspect of osteosarcoma treatment, particularly U2-OS type osteosarcomas, are not reported. The invention discloses new application of ethyl gallate to osteosarcoma treatment, and particularly relates to application of ethyl gallate to treatment of osteosarcomas, especially the U2-OS type osteosarcomas. Ethyl gallate has inhibition functions of different degrees on the osteosarcomas under high dosage, intermediate dosage and low dosage. As time goes by, the treatment effect of high-concentration ethyl gallate is better than 5-fluorouracil with the concentration the same as that of ethyl gallate in the market, and it is possible that ethyl gallate replaces 5-fluorouracil to treat the osteosarcomas.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

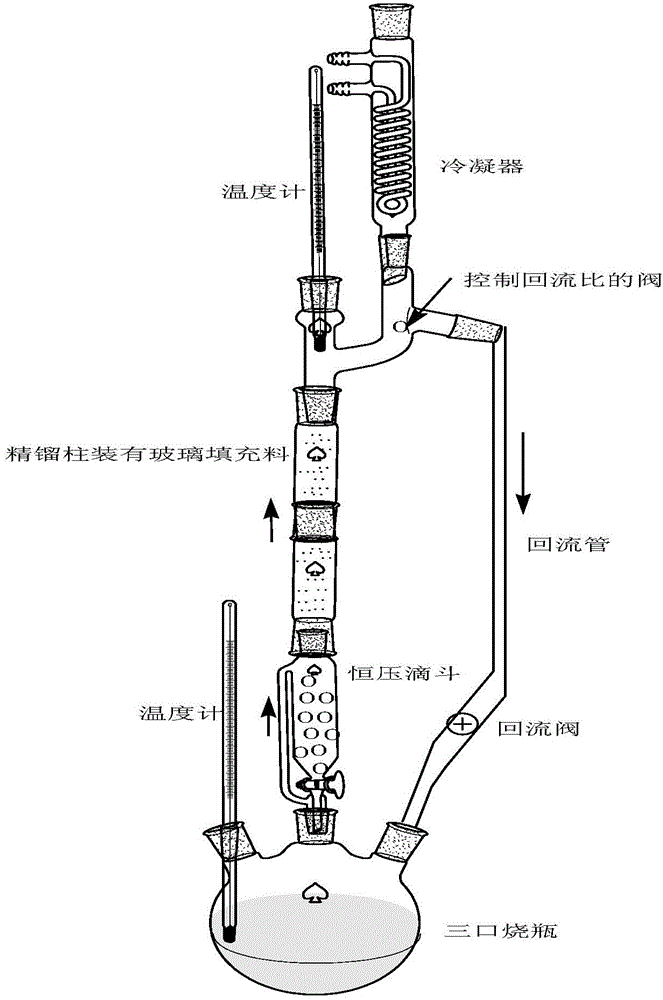

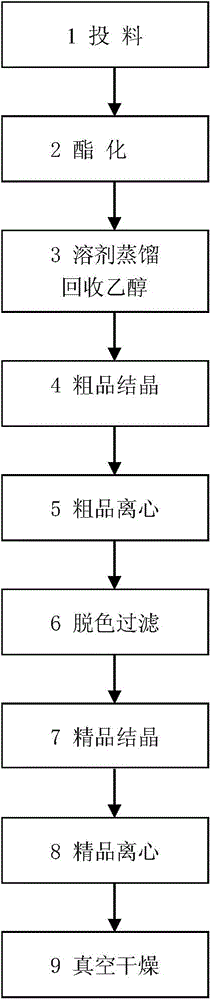

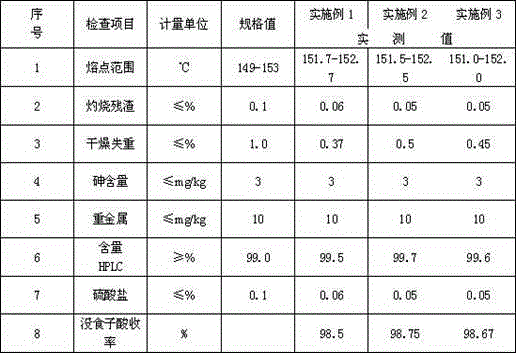

Synthesis method of ethyl gallate

InactiveCN104086416ALow costHigh yieldOrganic compound preparationCarboxylic acid esters preparationGallic acid esterReaction temperature

The invention relates to a synthesis method of ethyl gallate. The method comprises the following steps: carrying out esterification on gallic acid, absolute alcohol and sulfuric acid used as raw materials in a reaction kettle, sending water-ethanol mixed steam into a rectification tower directly connected with the reaction kettle to perform separation, controlling the reflux ratio to control the tower top temperature at 80-85 DEG C, returning the distilled ethanol into the reaction kettle to continue reaction, sending the cooled substance (water-ethanol mixture) on the rectification tower bottom into the reaction kettle via a constant-pressure dropping funnel (filled with a water-absorbing 3A molecular sieve) to continue reaction, carrying out esterification reaction for 8-10 hours while controlling the reaction temperature at 85-90 DEG C, distilling to recover the ethanol, adding soft water, cooling to crystallize, carrying out crude centrifugation, decolorizing, carrying out fine filtration, fine crystallization and fine centrifugation to obtain a fine product, and drying to obtain the ethyl gallate. The reaction procedure adopts the rectification tower and molecular sieve for water absorption, so that the reaction time is shortened, the product yield can reach 98.0%, and the ethyl gallate product purity is greater than 99.5%; and no water-carrying agent is needed in the reaction, thereby saving the cost and lowering the unit consumption.

Owner:遵义林源医药化工有限责任公司

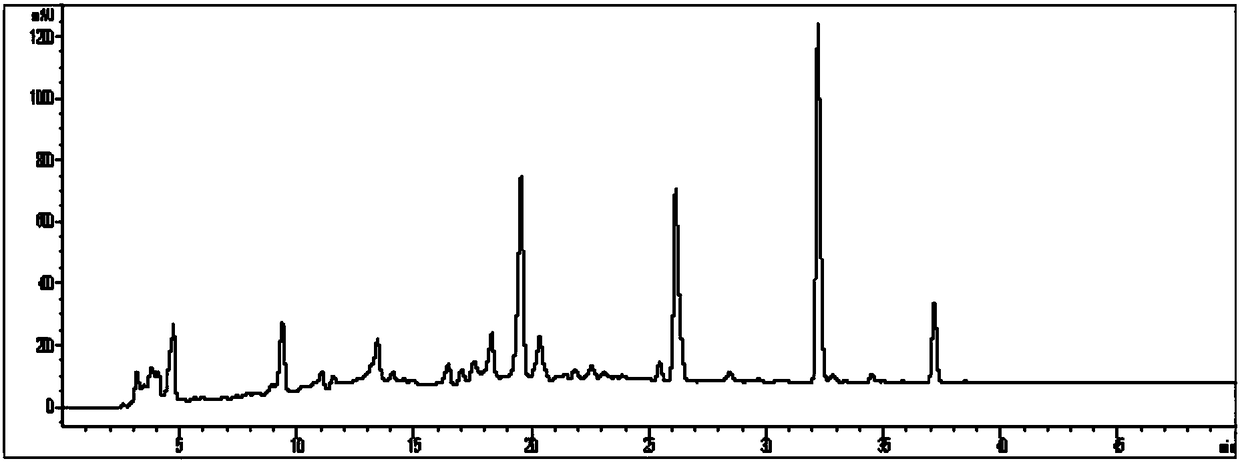

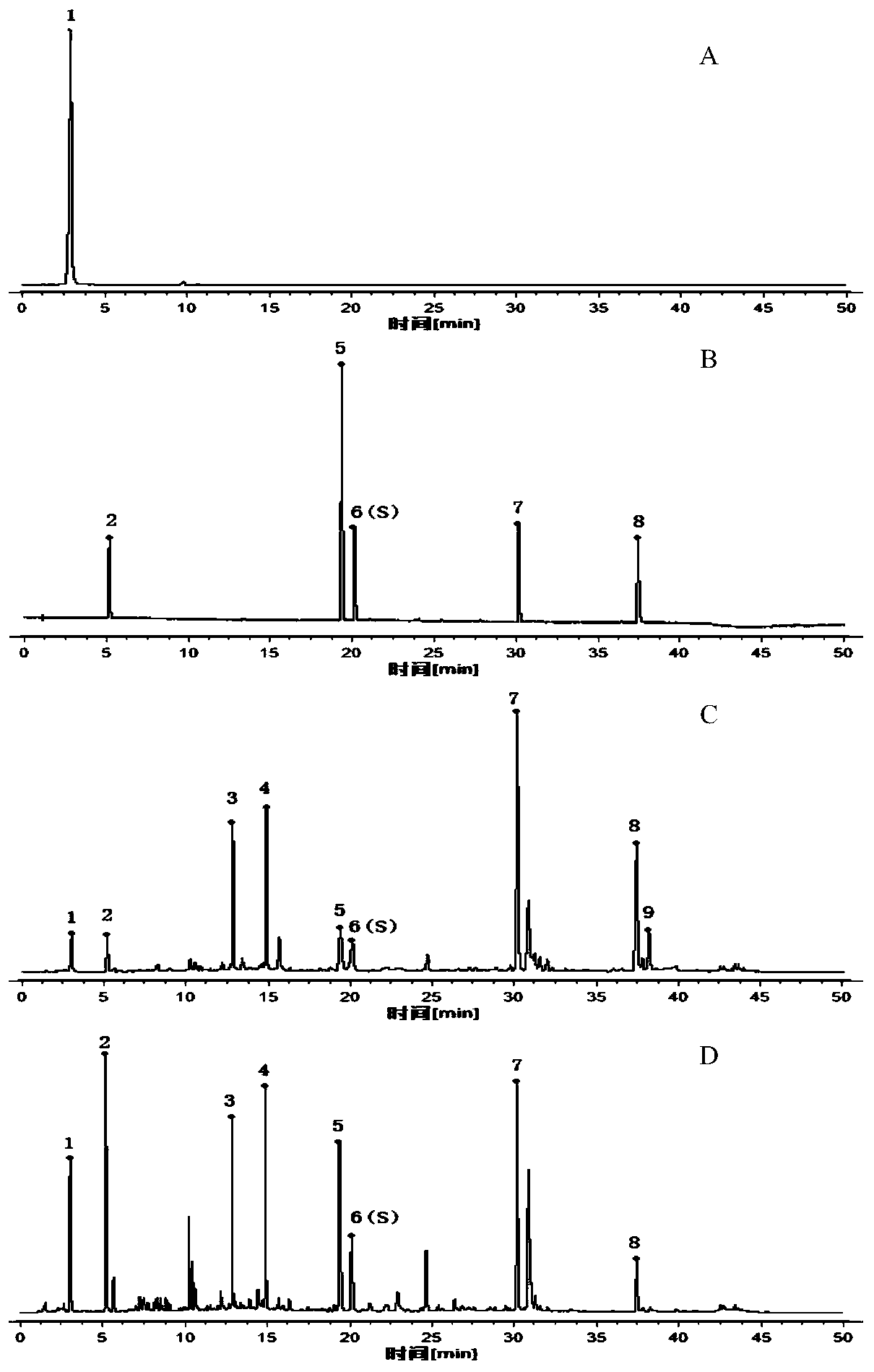

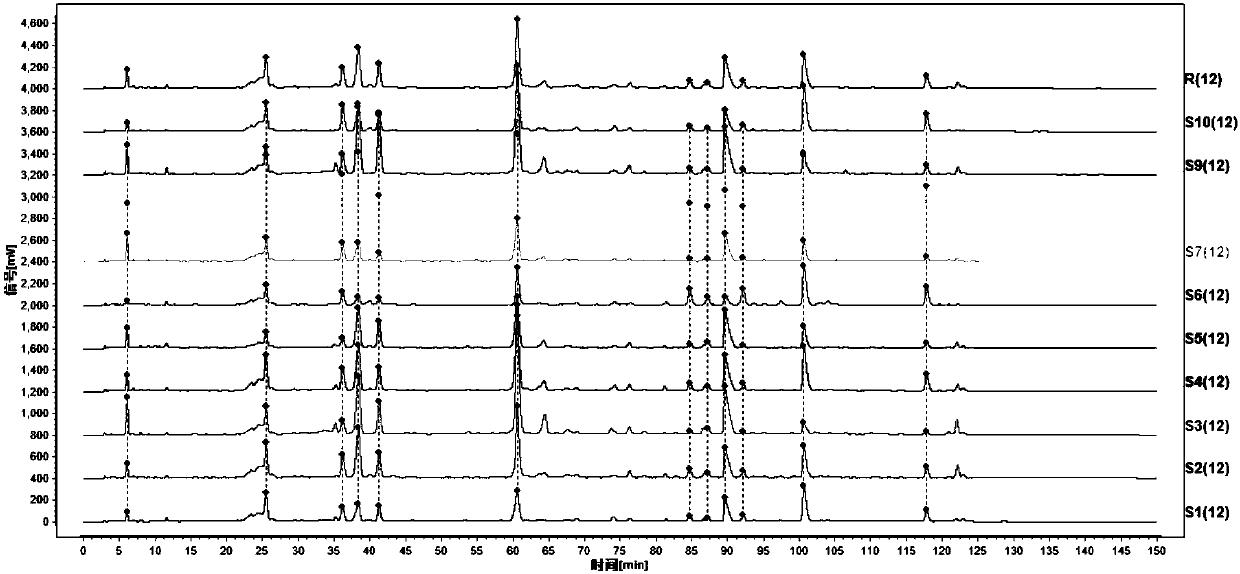

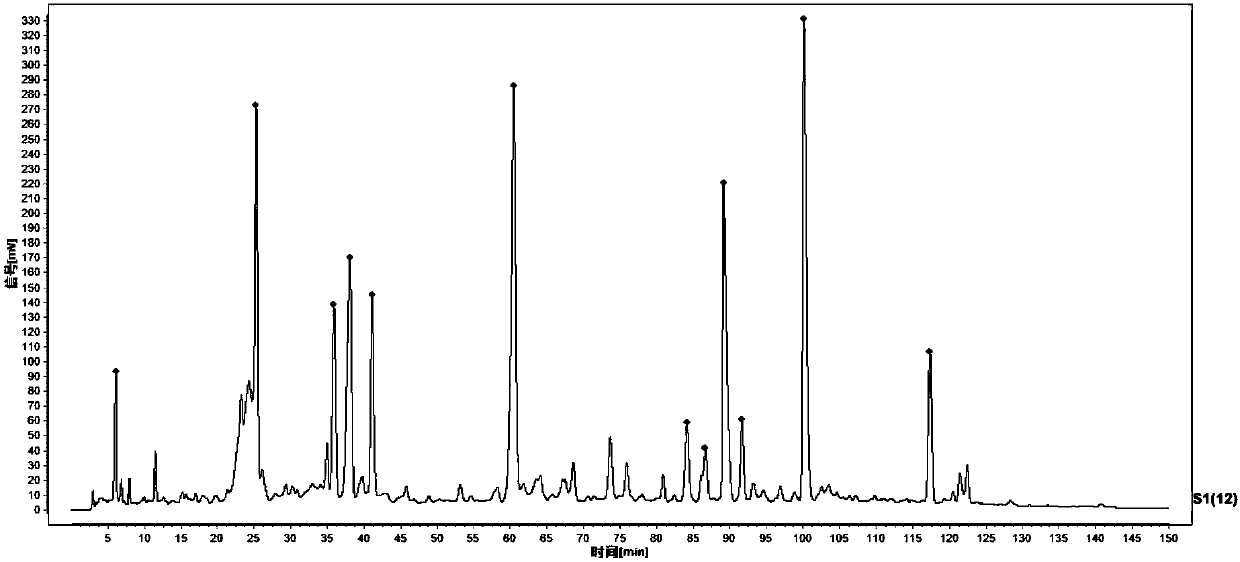

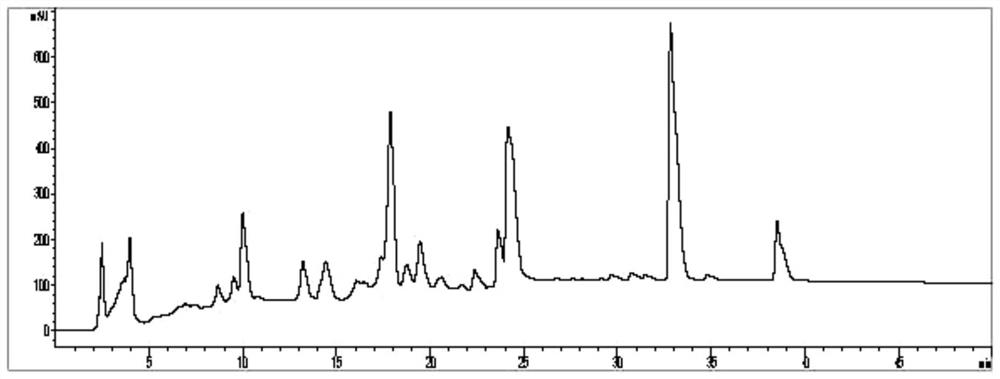

HPLC fingerprint for ethyl acetate position of longan leaf and establishing method of HPLC fingerprint

ActiveCN109856254AEffective massQuality improvementComponent separationAgainst vector-borne diseasesHplc fingerprintEthyl acetate

The invention discloses an HPLC fingerprint for the ethyl acetate position of a longan leaf and an establishing method of the HPLC fingerprint. The method comprises the steps that a solution of the tested object is prepared; a contrast solution including ethyl gallate, astragalin and quercetin is prepared; and HPLC is used for determination to obtain the fingerprint. The method has the advantagesof being rapid, accurate, high in precision, repeatability and stability, abundant in chromatographic peak information, and good in separating effect. The established HPLC fingerprint for the ethyl acetate position of the longan leaf can effectively represent the quality of the longan leaf, especially the quality of the ethyl acetate position of the longan leaf, and furhter the medical standard ofthe longan leaf is improved, the longan leaf quality evaluation system is improved, standardization of traditional Chinese medicines is facilitated, theoretical and practical basis is provided for comprehensive and effective control for the longan leaf quality, and accurate reliable basis is provided for the safety and effectiveness of clinical medicine.

Owner:GUANGXI UNIV OF CHINESE MEDICINE

Technology for producing Omega-3-ethyl gallate 90 from low-content ethyl ester fish oil

InactiveCN106349070AReduce usageReduce consumption costOrganic compound preparationCarboxylic acid esters preparationFish oilEthyl ester

The invention discloses a technology for producing Omega-3-ethyl gallate 90 from low-content ethyl ester fish oil. According to the technology, the low-content ethyl ester fish oil is directly subjected to urea inclusion reaction, subjected to decoloration, and then purified according to a molecular distillation method, so that the total content of the Omega-3-ethyl gallate 90 is not smaller than 93 percent, and the total content of EPA ethyl ester and DHA ethyl ester is not smaller than 85 percent. The technology does not need the complex process of performing decoloration and then rectification on a traditional product after the product is dissolved, thereby simplifying the process, is low in the amount of solvent, simple to operate, and suitable for large-scale production and operation, can obtain high-content Omega-3-ethyl gallate 90 products through a molecular distillation and purification mode, and effectively improves the product quality and the efficiency.

Owner:山东康曼生物科技有限公司

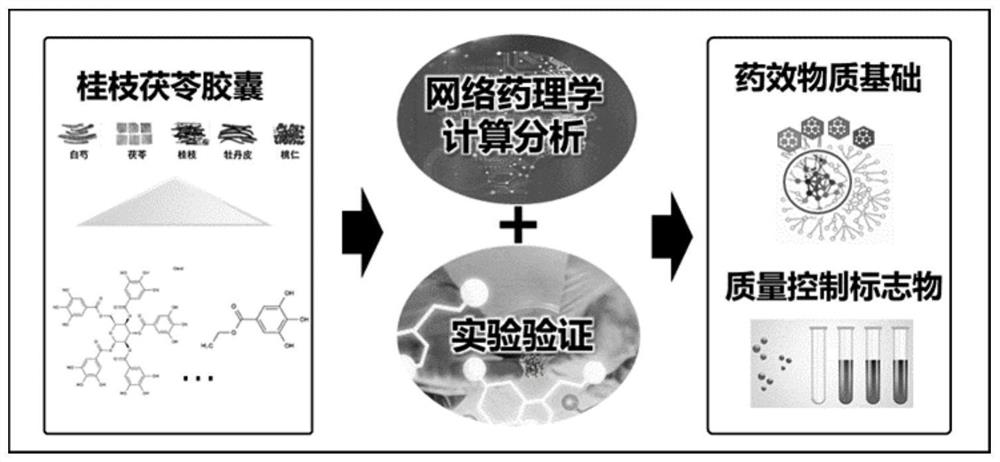

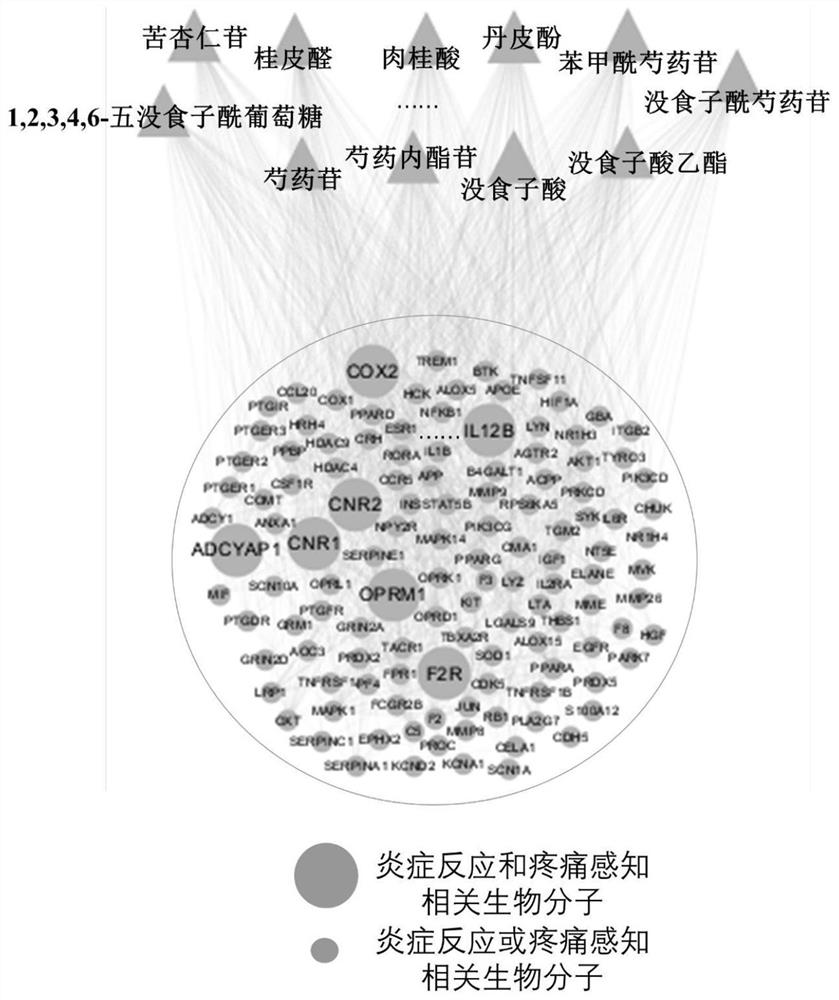

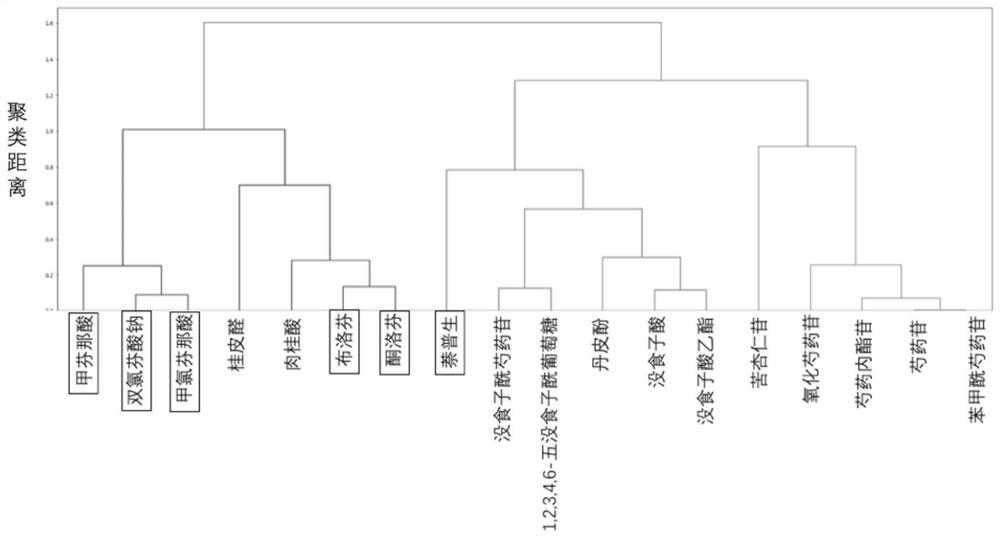

Application of substance to preparation of product for treating primary dysmenorrhea

The invention relates to application of a substance to preparation of a product for treating primary dysmenorrhea and application of the substance as a quality control marker of cassia twig and poria cocos capsules for treating primary dysmenorrhea. The substance comprises at least one of gallic acid, ethyl gallate, galloylpaeoniflorin and 1, 2, 3, 4, 6-pentagalloylglucose. The application comprises treatment of primary dysmenorrhea and quality control of the cassia twig and poria cocos capsule. The inventor carries out calculation, prediction and analysis through a network pharmacology method, and identifies a substance which can inhibit COX2 to play anti-inflammatory and analgesic effects and the like so as to treat primary dysmenorrhea in the cassia twig and poria cocos capsule, so that the substance can also be used as a quality control marker of the cassia twig and poria cocos capsule for intervening in COX2 to treat primary dysmenorrhea. In-vitro verification experiments show that the group of substances can inhibit COX2 enzyme activity.

Owner:JIANGSU KANION PHARMA CO LTD

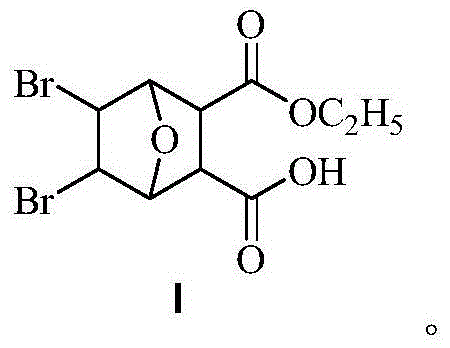

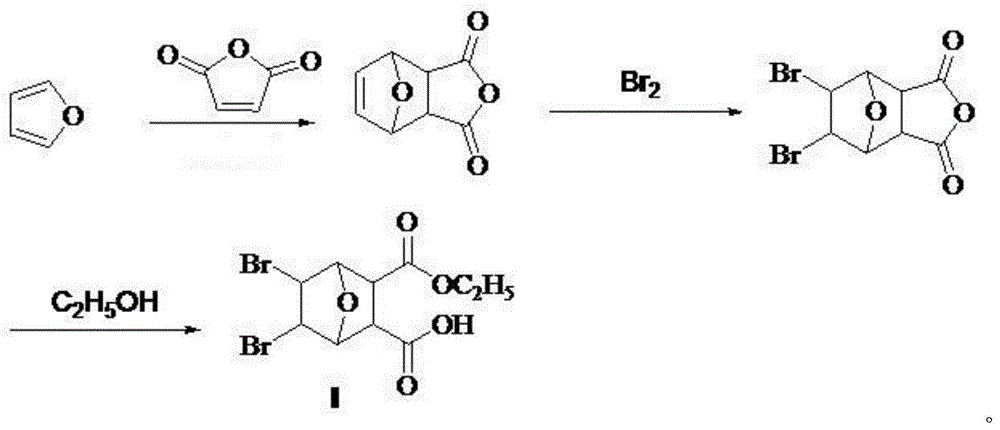

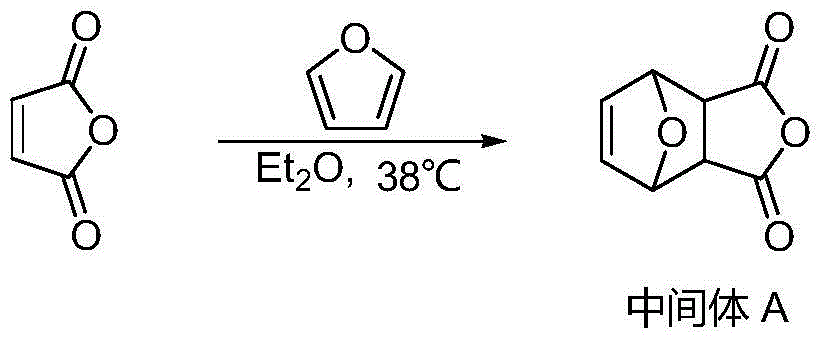

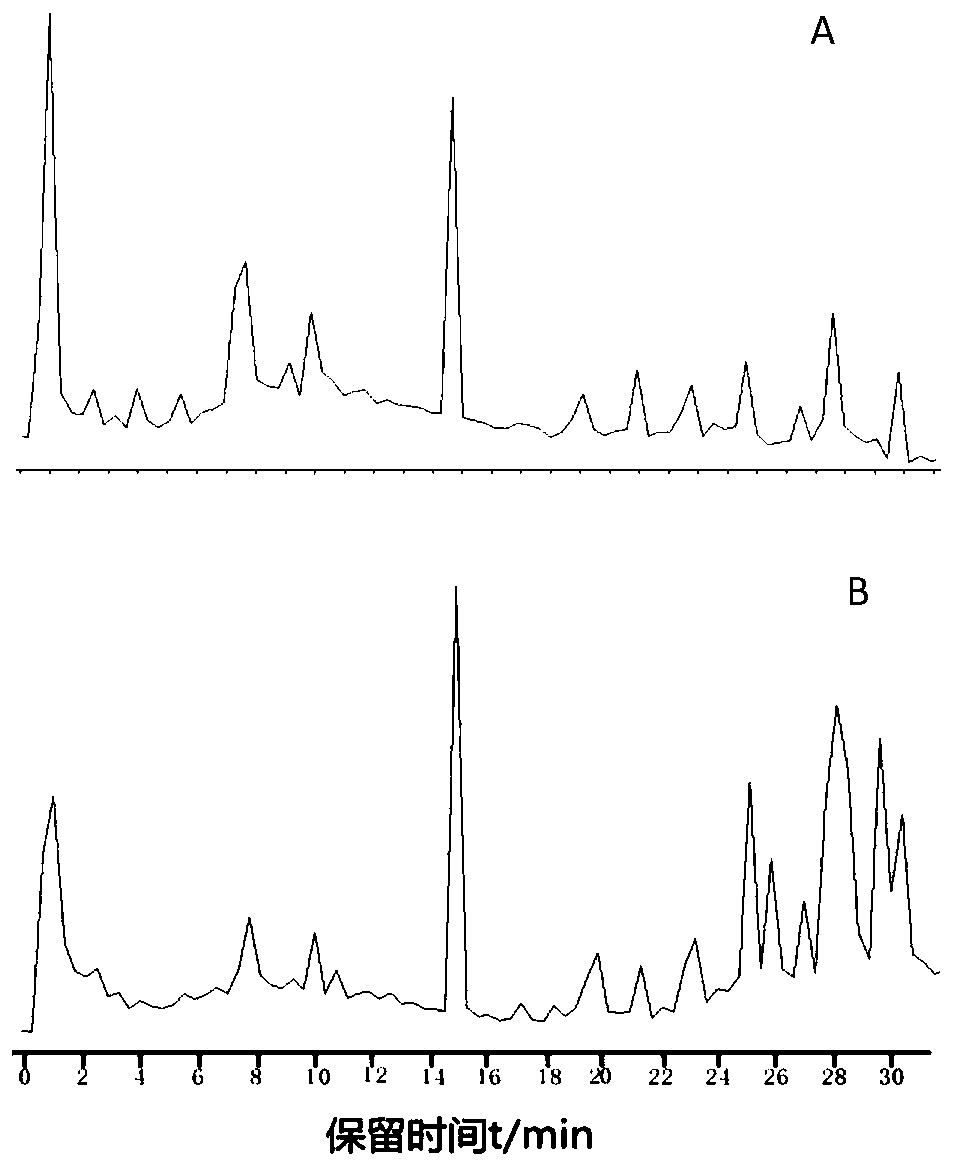

Bromo-norcantharidin ethyl gallate as well as preparation method and application thereof

ActiveCN104478892ALow toxicityGood effect against liver cancerOrganic chemistryAntineoplastic agentsBromineCantharidin

The invention discloses bromo-norcantharidin ethyl gallate, namely 5,6-dibromo norcantharidin ethyl gallate, wherein the structural formula of bromo-norcantharidin ethyl gallate is as shown in the formula I. As is proven by activity tests, bromo-norcantharidin ethyl gallate, namely open-cycle 5,6-dibromo norcantharidin ethyl gallate has a good anti-heptoma effect and can be used as an efficient and low-toxic cantharidin antineoplastic drug. The selectivity of a preparation process is good, raw materials are easy to obtain, the cost is low, the synthetic route is simple, the method is convenient to operate and conduct, toxicity of a product obtained through synthesis is low, the bromo-norcantharidin ethyl gallate is safe, the yield is high, and the purity is high. Therefore, the process has the characteristics of high efficiency, convenience and low cost.

Owner:GUIZHOU BAIQIANG PHARMA

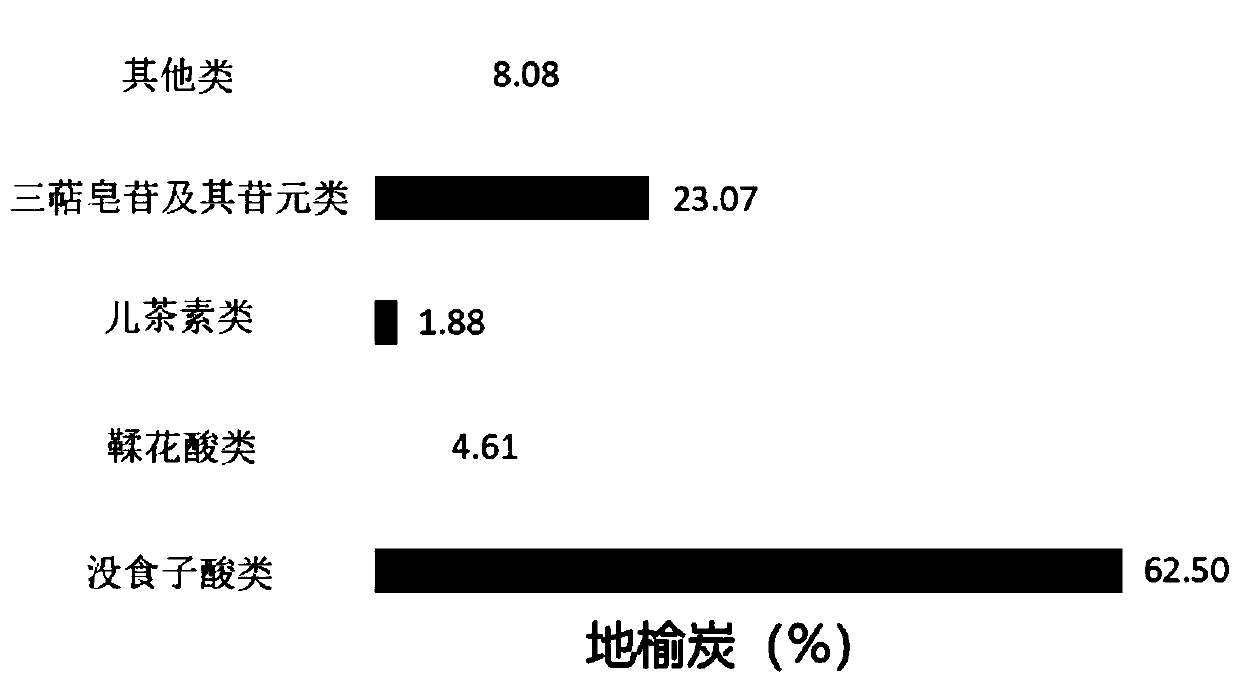

Application of carbonized sanguisorba roots in prevention and treatment of tinea corporis and cruris and tinea manus and pedis

The invention provides application of carbonized sanguisorba roots in prevention and treatment of tinea corporis and cruris and tinea manus and pedis, and application in preparation of medicines or daily necessities. Meanwhile, the invention provides application of one or more of gallic acid, pyrogallic acid, methyl gallate, ethyl gallate and protocatechuic aldehyde in prevention and treatment oftinea corporis and cruris and tinea manus and pedis, and application in preparation of medicines or daily necessities. Trichophyton rubrum is a main pathogenic bacterium of tinea corporis and cruris and tinea manus and pedis. The invention shows that the carbonized sanguisorba roots can significantly inhibit the growth of the trichophyton rubrum, and the effect is equivalent to that of common traditional Chinese medicines sophora flavescens and golden larch bark for skin tinea. After the carbonized sanguisorba roots are administrated, the growth of the trichophyton rubrum is remarkably inhibited through ocular lens observation. Clinical curative effect observation shows that after carbonized sanguisorba root gel with the content of 0.5% is used for treating for 4 weeks, the cure rate of patients reaches 96.15%, and half of the patients are cured. Meanwhile, the main components including the gallic acid, the pyrogallic acid, the methyl gallate, the ethyl gallate and the protocatechuic aldehyde in sanguisorba roots all have a remarkable effect of resisting the trichophyton rubrum, and the content is not reported.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

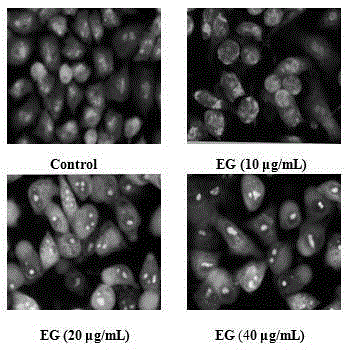

Application of ethyl gallate for preparing drugs for treating human colon carcinoma cell apoptosis

InactiveCN105232515APromotes Lovo chromatin condensationEasily brokenOrganic active ingredientsAntineoplastic agentsDiseasePharmacometrics

The invention discloses application of ethyl gallate for preparing drugs for treating colon carcinoma cell Lovo apoptosis. Pharmacology and cell biology experiments show that the ethyl gallate can effectively promote chromatin condensation of colon carcinoma cell Lovo, plasma membrane translocation of phosphatidylserine and breakage of internal DNAs of nucleuses and can induce cell apoptosis, and the action mechanism is closely related to improvement on expression level of Caspase-3, Caspase-8 and Caspase-9 proteins in the cells. The apoptosis-inducing effect of the ethyl gallate on the colon carcinoma cell Lovo is disclosed and subjected to quantitative analysis for the first time, research and development for new drugs with anti-cancer activity from the ethyl gallate from the perspective of apoptosis are benefitted, seeking for prevention and treatment of colon carcinoma diseases is benefitted, and new thoughts are provided for treatment of various tumors.

Owner:QIQIHAR MEDICAL UNIVERSITY

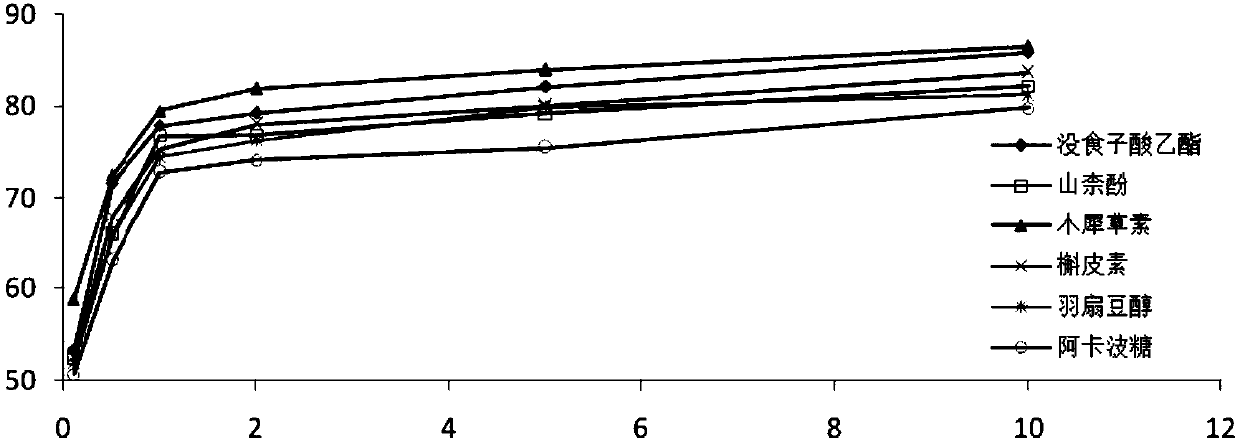

Method for extracting and separating active ingredients of hpyerglycemic effective part of longan leaves

PendingCN109646516ARich sourcesLow priceMetabolism disorderPlant ingredientsAlgluceraseAdditive ingredient

The invention discloses active ingredients of hpyerglycemic effective part which has good hypoglycemic effect by extracting and separating from the longan leaves by using modern separation means. Theactive ingredients include lupinol, ethyl gallate, kaempferol, luteolin, and quercetin. The active ingredients can be obtained by pulverizing the longan leaves and then extracting with ethanol, a percolate solution is decompressed to recover ethanol, and then an extract is obtained, and the extract is suspended by adding water, the petroleum ether and ethyl acetate are used for extraction to obtain a corresponding petroleum ether part and an ethyl acetate part, and the petroleum ether part and ethyl acetate part are taken and separated and purified by a silica gel column chromatography in a repeated mode and recrystallized. The pharmacological experiments show that the obtained compound has the function of controlling alpha-glucosidase activity.

Owner:GUANGXI UNIV OF CHINESE MEDICINE

Effective components of peony leaves as well as preparation method and application thereof

ActiveCN101574410BSimple preparation processLow costPharmaceutical delivery mechanismCardiovascular disorderDiseaseGallic acid ester

The invention relates to effective components of peony leaves, which are separated and obtained from the peony leaves and mainly comprise gallic acid and progallin A, wherein the content of the gallicacid is 35-70 percent, and the content of the progallin A is 15-30 percent. The invention also provides a preparation method of the effective components of the peony leaves by adopting macroporous resin purification and provides a medicine preparation of the effective components. The animal experiment result shows that the effective components can effectively prevent and treat cardiovascular andcerebrovascular diseases and especially have the functions of preventing and treating the coronary heart disease and the cerebral ischemia disease.

Owner:北大世佳科技开发有限公司

A kind of preparation method of cefditoren pivoxil

The invention relates to a preparation method of Cefditoren Pivoxil. The preparation method comprises steps as follows: 7-ACA (3-acetyloxymethyl-5-thio-7-amino-8-oxy-1-nitrogen heterobicyclic octyl-2-ene-2 carboxylic acid) is taken as a starting raw material and is subjected to iodination and Wittig reaction after silanization protection, and a Cefditoren parent nucleus 7-ATCA (7-amino-3-[(Z)-2-(4-methyl-5-thiazole) vinyl]-3-cephem-4-carboxylic acid) is generated; after amino protection of aminothiazole ethyl gallate, a compound 2 is produced from 7-ATCA under catalysis of AlMe3; the compound2 is subjected to an esterification reaction with iodomethyl pivalate under actions of a phase transfer catalyst and an acid adsorbent, the amino protection is removed, and a target product CefditorenPivoxil is obtained. According to the preparation method, reaction conditions are mild, product purity and yield are high, the process is stable, amplification is easy, and the method is applicable to industrial production.

Owner:SHANDONG YUXIN PHARMA CO LTD

A method to produce 2‑ chloric acid

Owner:SHANGHAI TAIHE INT TRADE CO LTD +1

Determination method of multiple components in longan leaves

ActiveCN108061763BAchieve quality controlEasy to controlComponent separationBiotechnologyAstragalus propinquus

The invention discloses a determination method for multi-component content in Longan leaves. In the determination method, the high-performance liquid chromatography is used to determine the content ofethyl gallate, astragalin, quercetin, luteolin and kaempferol in the longan leaves simultaneously. The method has the advantages of high efficiency, accuracy, good resolution, repeatability and stability, simple and easy operation, and can effectively control the quality of the longan leaves.

Owner:GUANGXI UNIV OF CHINESE MEDICINE

Breath freshening toothpaste and preparation method thereof

PendingCN113712831AWell mixedImprove coordinationAntibacterial agentsCosmetic preparationsArginine ethylesterArginine

The invention relates to the technical field of articles for daily use, in particular to breath freshening toothpaste and a preparation method thereof. The breath freshening toothpaste is prepared from a toothpaste component, a deodorant and deionized water, wherein the toothpaste component comprises the following components: sorbitol, hydrated silica, polyethylene glycol, glycerol, edible essence, tetrasodium pyrophosphate, methylparaben, xanthan gum, sodium methyl cocoyl taurate, cocamidopropyl betaine, a plant flower extract and trichlorogalactose; and the deodorant is composed of trehalose, zinc citrate, bamboo leaf flavone, and a cross-linked polymer of PCA cocoyl arginine ethyl gallate and acrylic acid (acrylate) / C10-30 alkanol acrylate. The breath freshening toothpaste has the advantages of bacteriostasis, inflammation diminishing, periodontal care, lasting fragrance retention, degerming, long effective time and tartar removal. The method has the advantages that the formed toothpaste can be prepared, and the freshening effect and the degerming effect of the toothpaste can be improved.

Owner:GUANGDONG SOUTHERN JIELING TECH IND

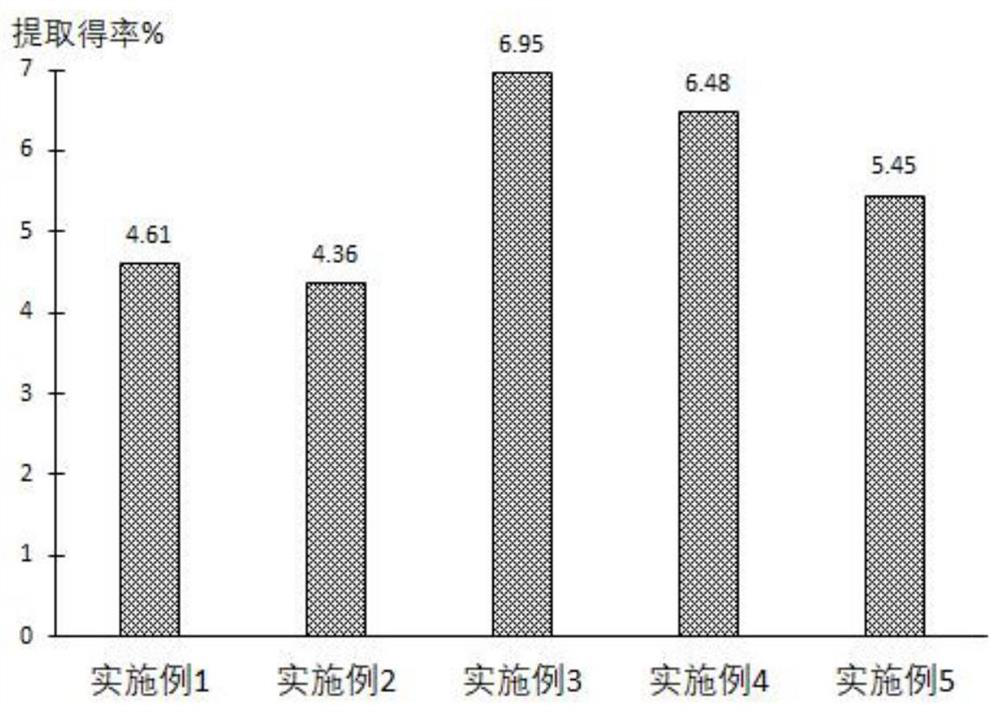

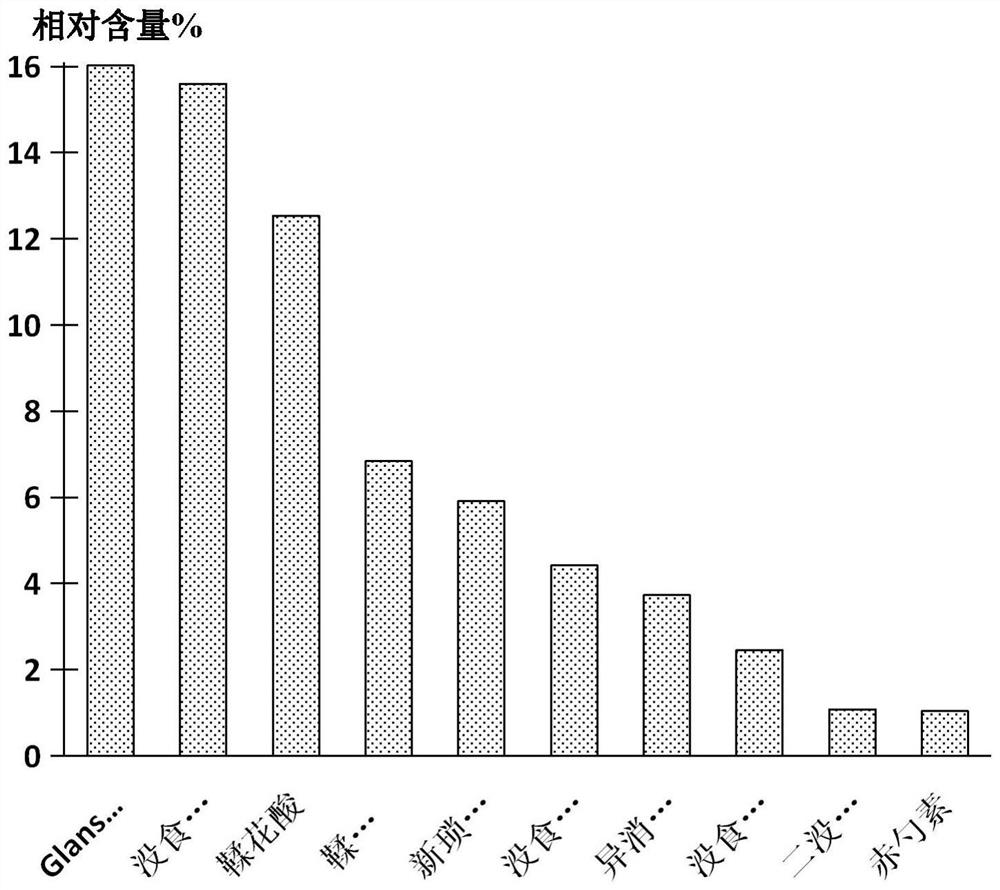

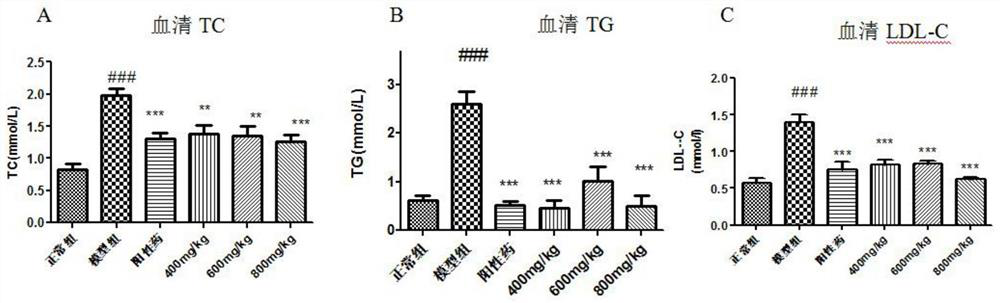

Walnut meal polyphenol with lipid-lowering effect as well as preparation method and application of walnut meal polyphenol

PendingCN114404473AHigh extraction rateImprove the development and utilization of resourcesMetabolism disorderFood adsorptionBiotechnologyGallic acid ester

The invention discloses walnut meal polyphenol with a lipid-lowering function as well as a preparation method and application of the walnut meal polyphenol. The walnut meal polyphenol has the effects of lowering triglyceride (TG), total cholesterol (TC) and low-density lipoprotein cholesterol (LDL-C) of hyperlipemia serum and liver; the walnut dreg polyphenol is prepared from the following components in percentage by weight: 16.02% of Glansginin A, 15.60% of gallic acid, 12.53% of ellagic acid, 6.84% of ellagic acid-4-O-xyloside, 5.91% of neofusasin I, 4.42% of ethyl gallate, 3.73% of isoburning fat, 2.46% of galloylglucose, 1.08% of digalloylglucose and 1.04% of erythrosine. According to the preparation method, the extraction yield of the walnut meal polyphenol is 4.93%-6.95%. According to the method, a response surface design reflux extraction technology is adopted and is combined with the reflux extraction technology, so that the extraction rate of the walnut meal polyphenol is greatly improved, and the extraction period is effectively shortened; the preparation method disclosed by the invention is simple and convenient, easy to operate, short in time consumption and low in cost, can realize rapid deastringency of the walnut meal, can efficiently produce the functional component walnut meal polyphenol, and effectively expands resource development and utilization of the walnut meal.

Owner:YUNNAN UNIV OF TRADITIONAL CHINESE MEDICINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com