Full-sealing process for preparing azamethiphos cleanly

A methyl pyridine phosphorus and cleaning technology is applied in the technical field of fully sealed and cleaned preparation of methyl pyridine phosphorus, can solve problems such as unfavorable environmental protection, impact on sealing, easily affecting production environment and human health, etc. Environmental protection, increasing contact time, and preventing harmful gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in further detail below based on the accompanying drawings. It should be understood that the specific embodiments described here are only examples, and are not intended to limit the protection scope of the present invention.

[0027] The process for preparing picoline in a fully sealed and clean process provided by the invention comprises the following steps:

[0028] Step 1, providing a reaction device.

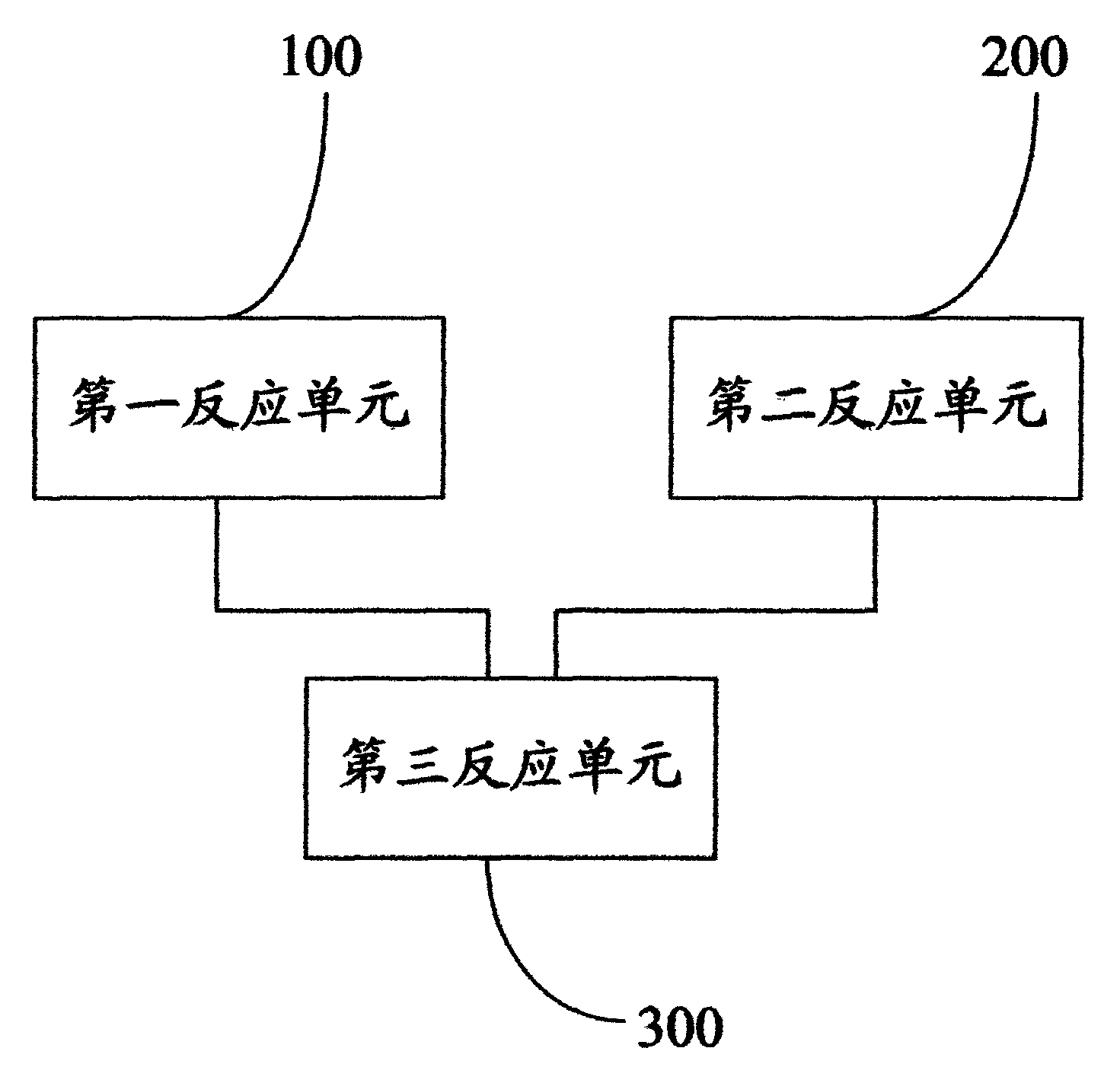

[0029] See Figure 4 , is a block diagram of the reaction device, which includes a first reaction unit 400, a second reaction unit 500, and a third reaction unit 600 connected to the first and second reaction units 400, 500.

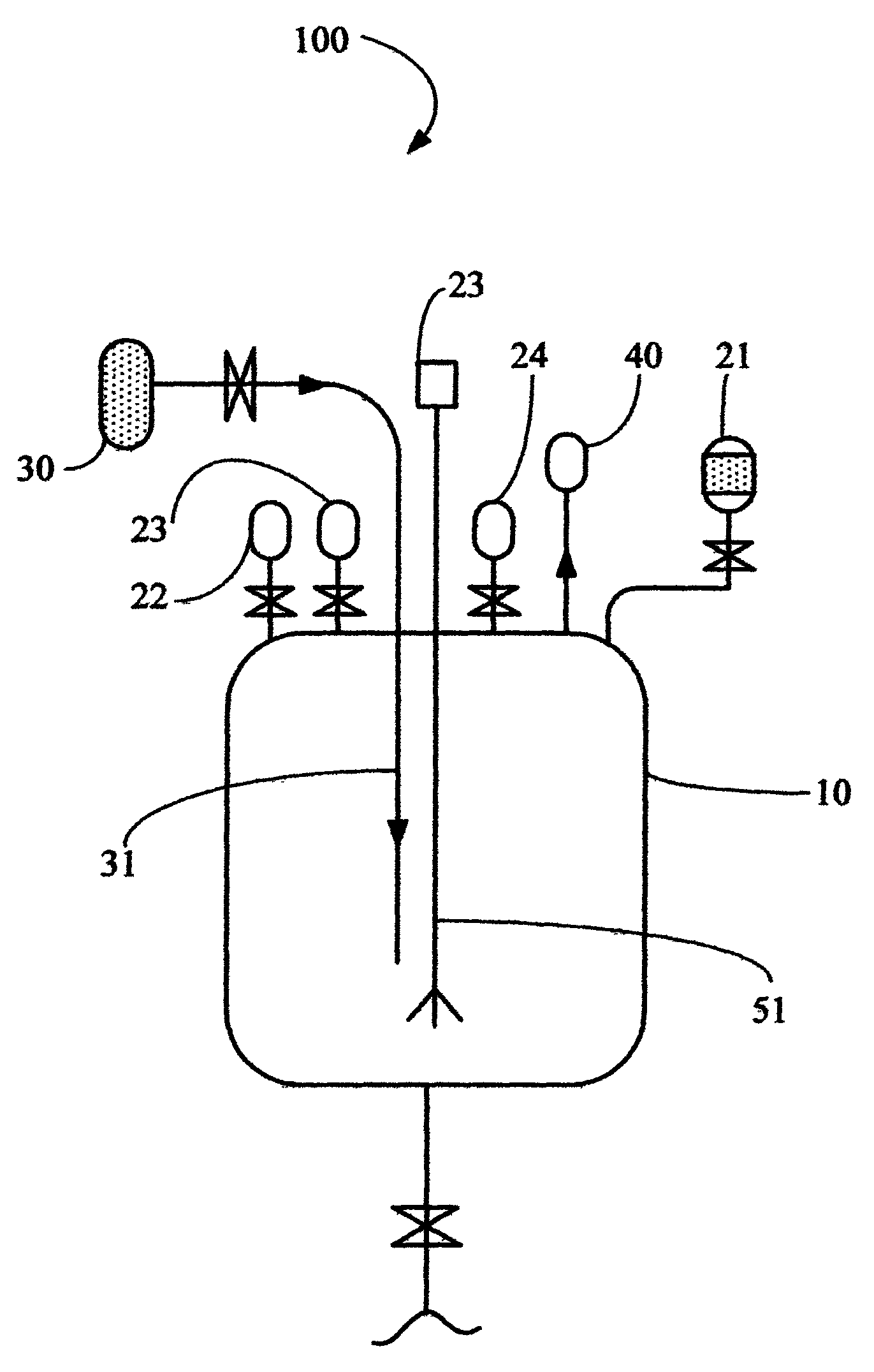

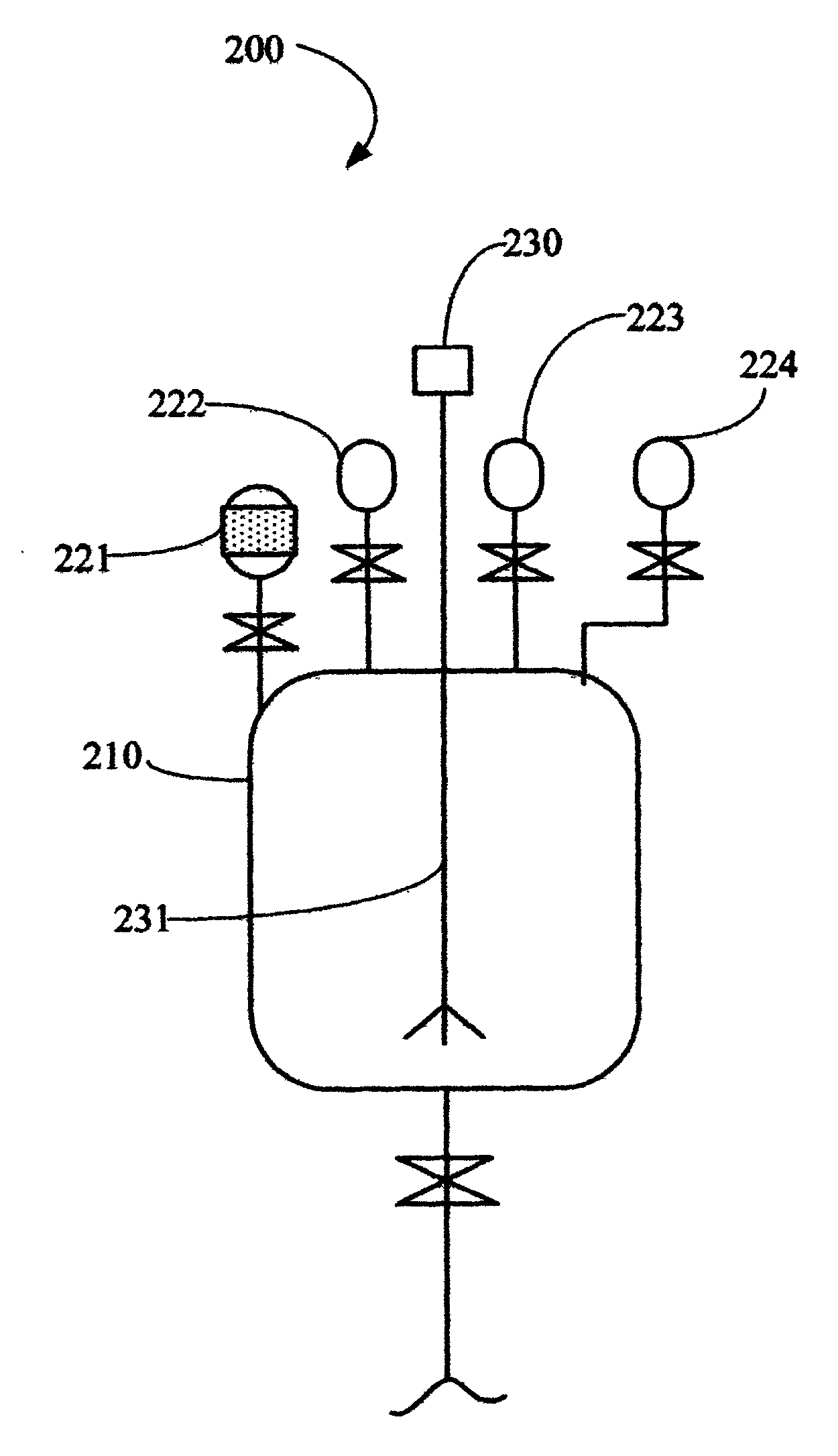

[0030] See Figure 5 , the first reaction unit 400 includes a cyclone kettle 410, a plurality of first storage tanks (not shown in the figure) communicating with the cyclone kettle 410, a gas storage tank 430, a waste gas recovery tank 440 and a first A powder-liquid mixing pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com