A reaction device for fully sealed preparation of picoline

A technology of picoline phosphorus and a reaction device is applied in the field of reaction devices that can be fully sealed to prepare picoline phosphorus, can solve the problems of easily affecting the production environment and human health, adverse environmental protection, affecting sealing and the like, and achieves eliminating harmful effects. Gas leakage, beneficial to environmental protection, effect of increasing contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in further detail below based on the accompanying drawings. It should be understood that the specific embodiments described here are only examples, and are not intended to limit the protection scope of the present invention.

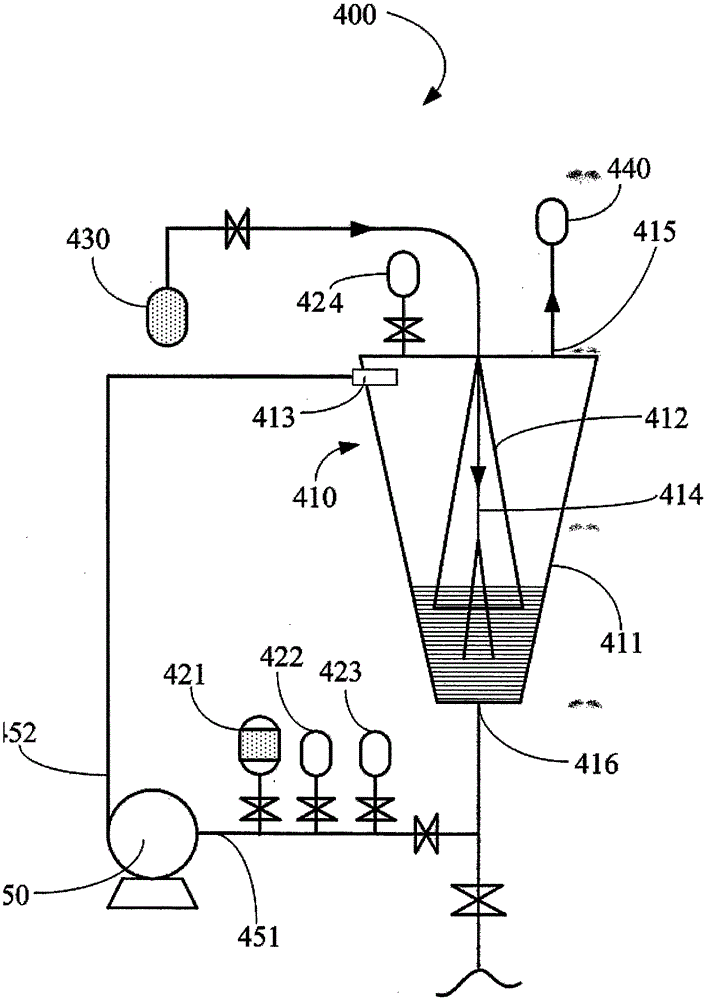

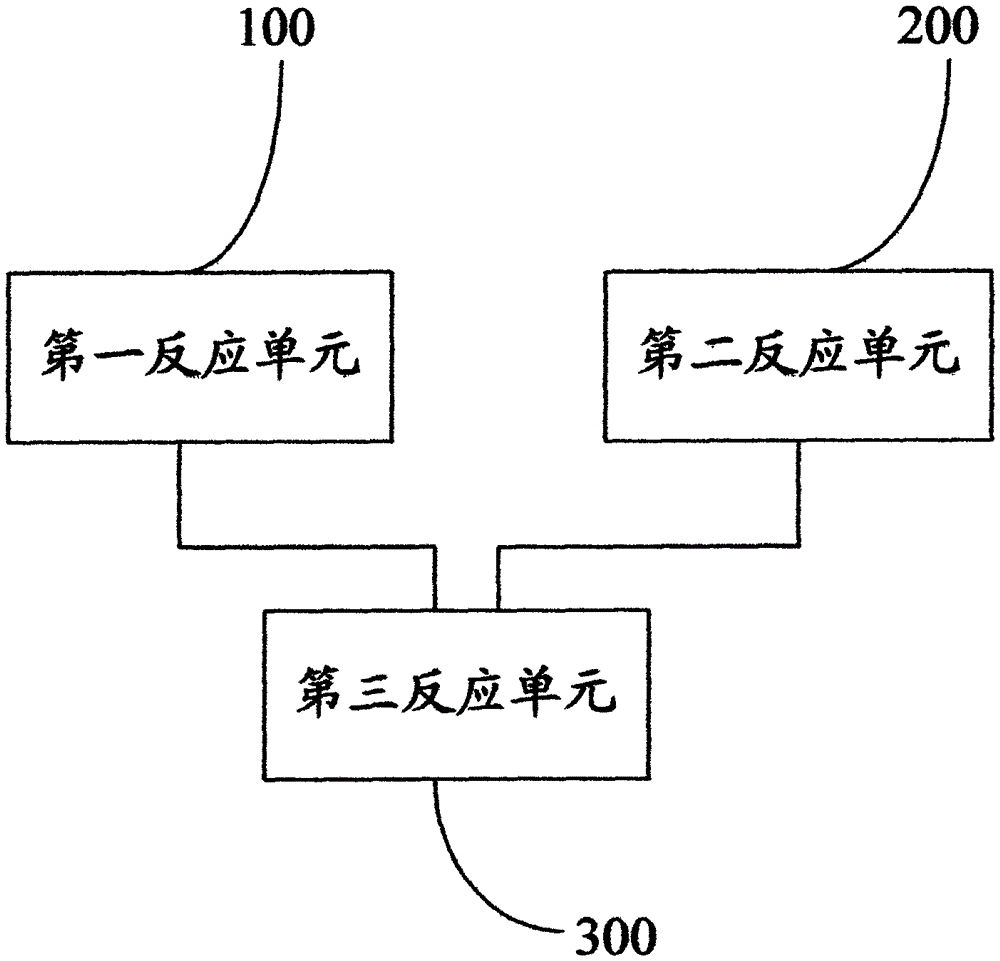

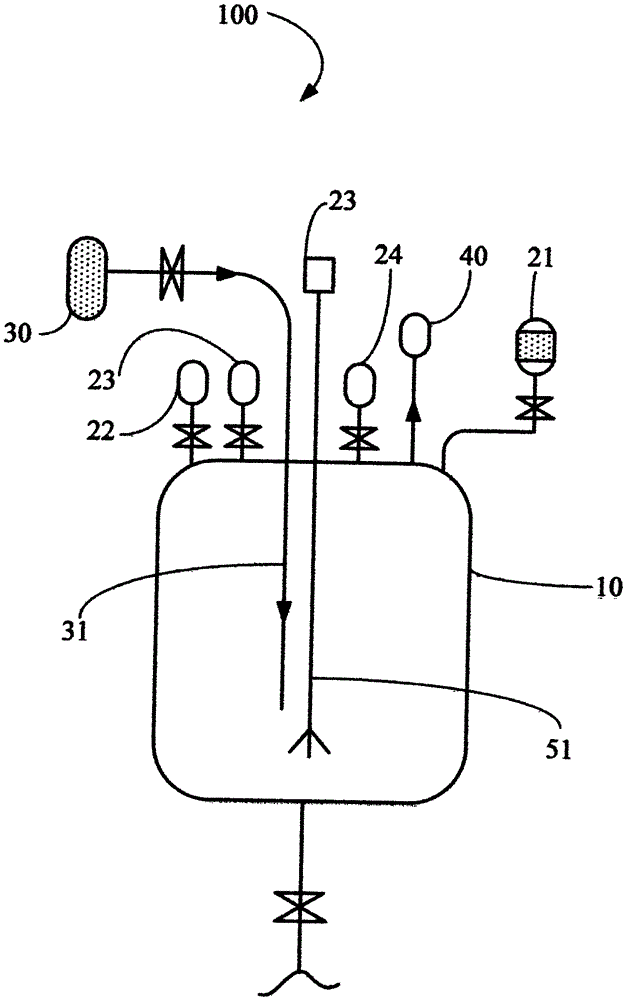

[0027] see Figure 4, is a block diagram of a fully sealed reaction device for the preparation of picoline provided by the present invention. The device includes a first reaction unit 400 , a second reaction unit 500 , and a third reaction unit 600 connected to the first and second reaction units 400 and 500 . The first reaction unit 400 is used to prepare intermediate branched chlorinated products. The second reaction unit 500 is used to prepare intermediate phosphorothioate. The above-mentioned two kinds of intermediate products, ie branched chain chlorinated products and phosphorothioate, finally enter the third reaction unit 600, and produce the final product pyridinate after c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com