Oil well cement additive used for preventing H2S/CO2 co-corrosion, and preparation method and application thereof

A technology of oil well cement and admixture, which is applied in the field of petroleum exploration, can solve problems such as corrosion, and achieve the effect of improving compressive strength and gas permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

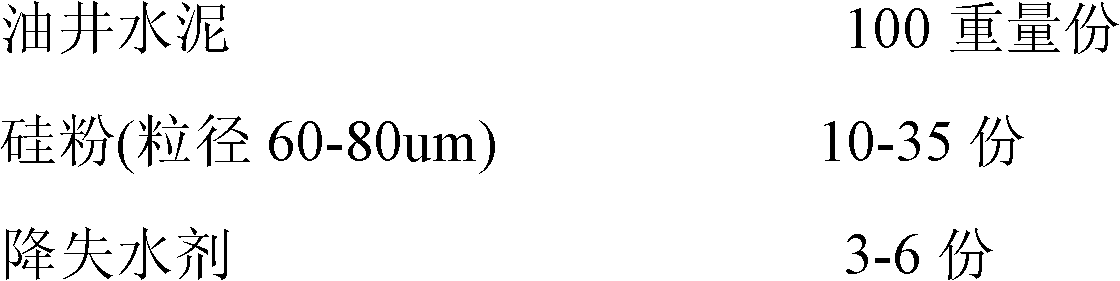

Method used

Image

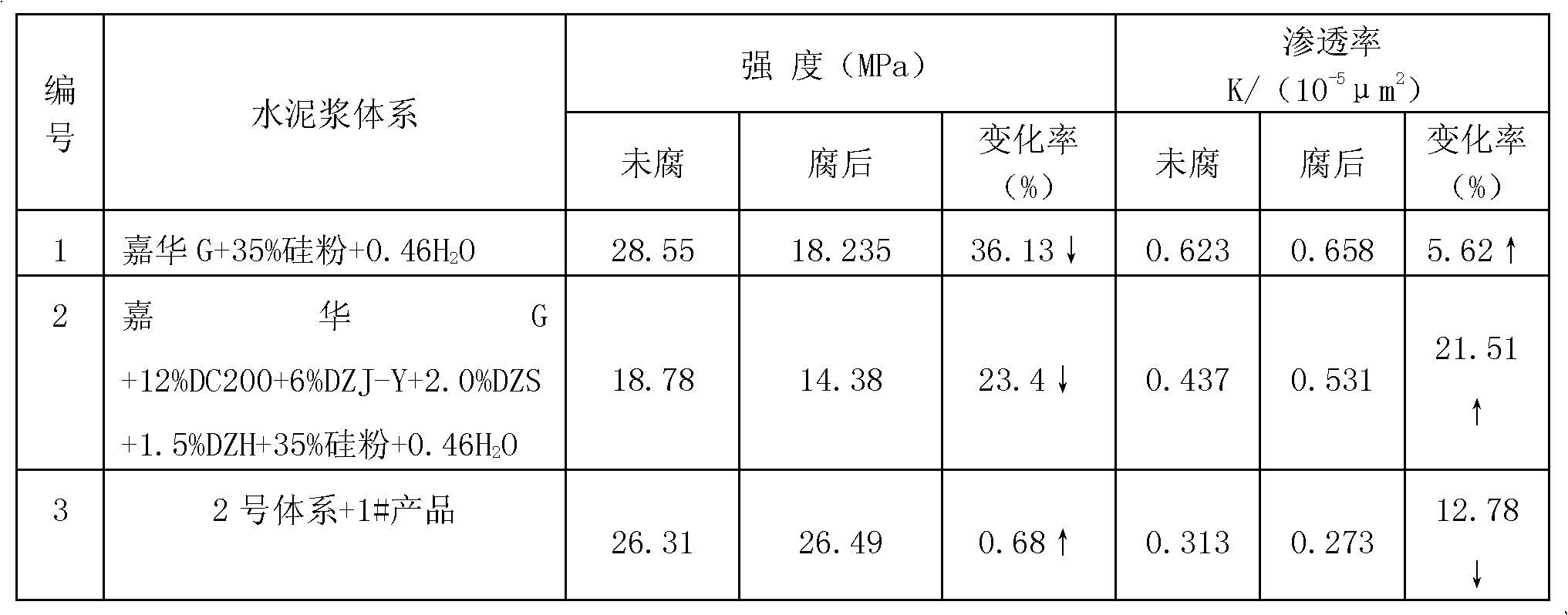

Examples

Embodiment 1

[0056] 100 parts by weight of fly ash and 35 parts of slag are ground in a dry ball mill and mixed evenly to a fineness of 500 meshes, and then put into a double-screw mixer. Add 12 parts of microsilica fume, 35 parts of superfine alumina, 12 parts of organic material pitch and 7 parts of sodium methyl siliconate for mixing, repeat mixing for 2 hours, and obtain product powder 1# after being uniform.

Embodiment 2

[0058] 100 parts of fly ash, 25 parts of slag, ground in a dry-type ball mill and mixed evenly to reach a fineness of 500 meshes, then put into a double-screw mixer, add 27 parts of micro-silica fume, 12 parts of ultra-fine alumina Parts, 27 parts of organic material asphalt and 9 parts of sodium methyl siliconate were mixed and mixed repeatedly for 2 hours, and the product powder 2# was obtained after being uniform.

Embodiment 3

[0060] Take 100 parts of fly ash and 30 parts of slag, grind them in a dry ball mill and mix them evenly to reach a fineness of 500 meshes, then put them into a double-screw mixer, add 25 parts of microsilica fume, superfine alumina 30 parts, 25 parts of organic material asphalt, and 8 parts of sodium methyl siliconate were mixed and mixed repeatedly for 2 hours, and the product powder 3# was obtained after being uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com