Method for reclaiming zinc and iron by directly reducing blast furnace gas mud through microwave

A blast furnace gas mud and microwave technology, applied in the treatment of zinc-containing gas mud, microwave direct reduction of blast furnace gas mud to recover zinc and iron, can solve problems affecting the smooth production of ironmaking, reducing the service life of the blast furnace, reducing the output of the blast furnace, etc. Achieve obvious social and economic benefits, improve life expectancy, and ensure the effect of resource recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

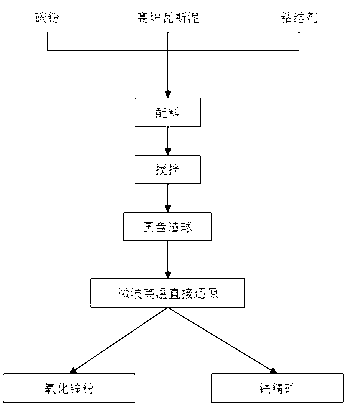

Image

Examples

Embodiment 1

[0017] Using blast furnace gas mud from a steel company in Yunnan as raw material: the main components (wt, %) are: TFe 38.15, Zn 6.88, C 10.43, SiO 2 7.40, Al 2 o 3 3.26.

[0018] (1) According to the amount of binder added is 2% of the mass of the blast furnace gas mud, mix the blast furnace gas mud with the binder polyvinyl alcohol, and then add 10% of the total mass of the blast furnace gas mud and the binder polyvinyl alcohol After the carbon powder is pelletized, the particle size of the pellets is 3mm;

[0019] (2) Put the pellets obtained in step (1) into a ceramic crucible, place them in a microwave high-temperature reaction chamber, and heat them with microwaves at a frequency of 2450MHz, a power of 5KW, and a heating rate of 30°C / min to 1200°C, and keep warm 1h, the zinc oxide in the gas mud is reduced and then volatilized in the form of zinc vapor;

[0020] (3) Cooling the zinc vapor produced in step (2) to obtain superfine zinc oxide powder, and recovering t...

Embodiment 2

[0023] Using blast furnace gas mud from a steel company in Yunnan as raw material: the main components (wt, %) are: TFe 38.15, Zn 6.88, C 10.43, SiO 2 7.40, Al 2 o 3 3.26.

[0024] (1) According to the amount of binder added is 1.5% of the mass of the blast furnace gas mud, mix the blast furnace gas mud with the binder polyvinyl alcohol, and then add 15% of the total mass of the blast furnace gas mud and the binder polyvinyl alcohol Balling after toner;

[0025] (2) Put the pellets obtained in step (1) into a ceramic crucible, place them in a microwave high-temperature reaction chamber, and heat them with microwaves at a frequency of 2500MHz, a power of 1KW, and a heating rate of 30°C / min to 1150°C, and keep warm 1.5h, the zinc oxide in the gas mud is reduced and volatilized in the form of zinc vapor;

[0026] (3) Cooling the zinc vapor produced in step (2) to obtain superfine zinc oxide powder, and recovering the reduction slag to obtain iron concentrate after selection...

Embodiment 3

[0029] (1) According to the amount of binder added is 1% of the mass of the blast furnace gas mud, mix the blast furnace gas mud with the binder polyvinyl alcohol, and then add 20% of the total mass of the blast furnace gas mud and the binder polyvinyl alcohol Balling after toner;

[0030] (2) Put the pellets obtained in step (1) into a ceramic crucible, place them in a microwave high-temperature reaction chamber, and heat them with microwaves at a frequency of 2400MHz, a power of 6KW, and a heating rate of 30°C / min to 1100°C, and keep warm 2h, the zinc oxide in the gas mud is reduced and then volatilized in the form of zinc vapor;

[0031] (3) Cooling the zinc vapor produced in step (2) to obtain superfine zinc oxide powder, and recovering the reduction slag to obtain iron concentrate after selection and separation.

[0032] The removal rate of zinc in the treated gas mud can reach 97.2%, the grade of collected zinc oxide reaches 91.9%, the TFe in metallized slag reaches 60....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com