Preparation method of material with modified titanium surface for enhancing combination strength of titanium porcelain

A technology of surface modification and bonding strength, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., and can solve problems such as affecting titanium-ceramic bonding and poor adhesion of oxide film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

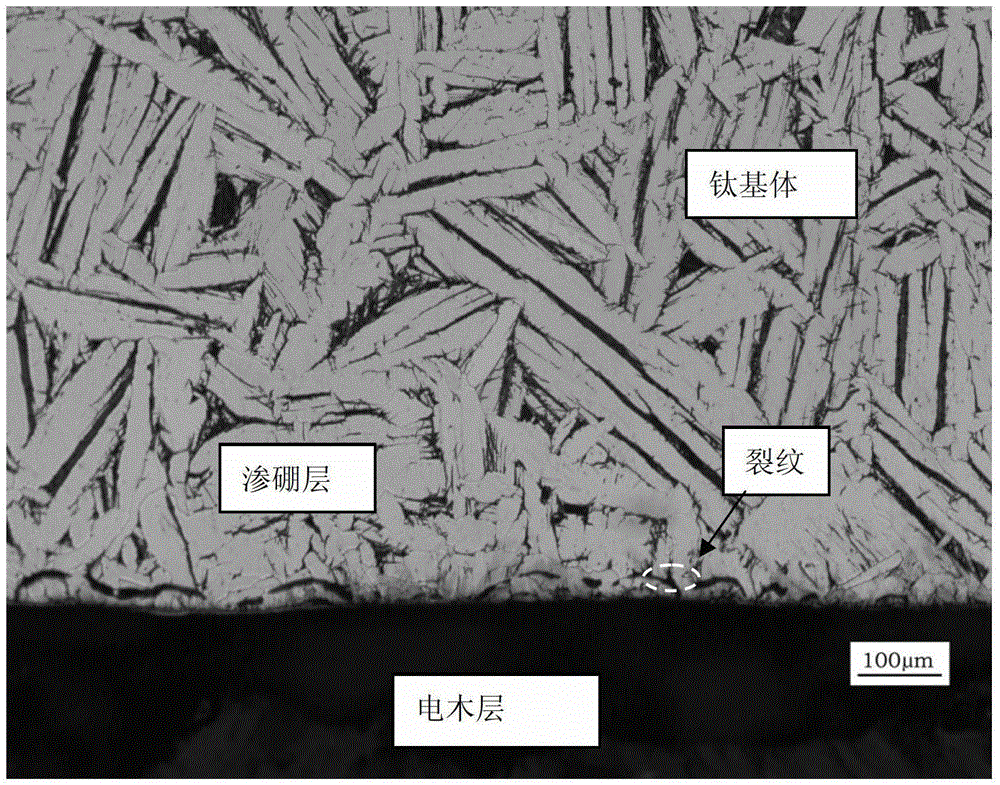

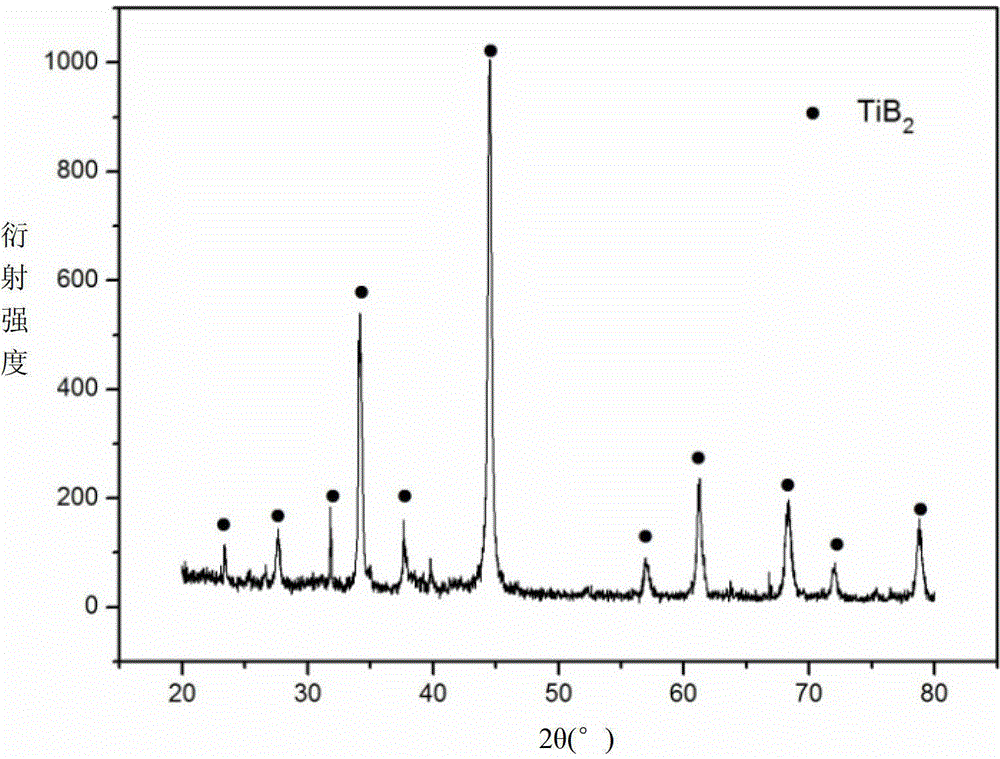

Embodiment 1

[0024] Take 20% Na 2 B 4 o 7 and 60%B 4 C as boronizing source, 10% KBF 4 As a catalyst, 10% SiC is used as an additive, and 1% of the total mass of the above-mentioned substances is graphite as a reducing agent. Put all the above materials into a jar and shake well to make a complex boride. After the prepared composite boride was put into an alumina crucible, the pure titanium sample was embedded in the composite boride. Put the crucible into the tube furnace, exhaust the air in the tube furnace with Ar gas, and then heat treatment. The heat treatment process is as follows: when the temperature is raised, the temperature is raised from room temperature to 100°C for 60 minutes, from 100°C to 950°C for 120 minutes, and kept for 50 minutes. ; When cooling down, from 950°C to 400°C for a total of 80 minutes, then stop the heating program and air cool to room temperature. Take the titanium sample out of the composite boride, clean the surface, remove the residue of the compo...

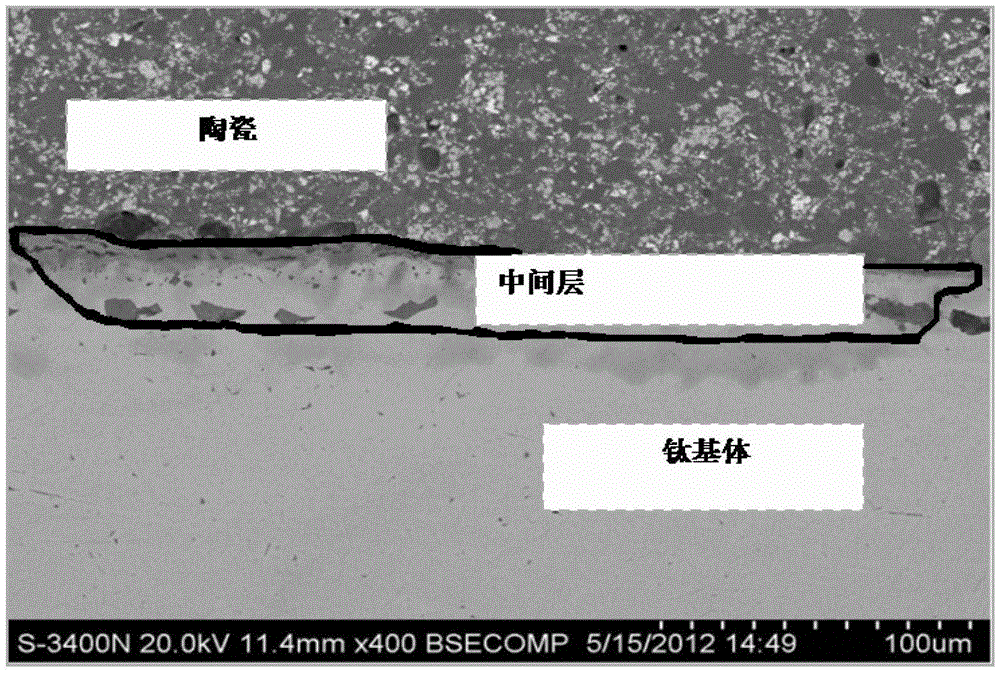

Embodiment 2

[0028] Take 30% Na 2 B 4 o 7 and 40% B 4 C as boronizing source, 15% KBF 4 As a catalyst, 15% SiC is used as an additive, and 2% of the total mass of the above-mentioned substances is graphite as a reducing agent. Put the above materials into the jar and shake well to make a complex boride. After the prepared composite boride was put into an alumina crucible, the pure titanium sample was embedded in the composite boride. Put the crucible into the tube furnace, exhaust the air in the tube furnace with Ar gas and heat treatment. The heat treatment process is as follows: when the temperature is raised, the temperature is raised from room temperature to 100°C for 60 minutes, from 100°C to 950°C for 120 minutes, and kept for 150 minutes. ; When cooling down, from 950°C to 400°C for a total of 80 minutes, then stop the heating program and air cool to room temperature. Take the titanium sample out of the composite boride, clean the surface, remove the residue of the composite b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com