Earthenware tile assembly, preparing die thereof, earthenware tile stone wall and heat insulation unit of earthenware tile assembly

A technology of ceramic bricks and components, applied in molds, insulation, walls, etc., can solve problems that do not meet the national energy-saving and environmental protection development goals, are not conducive to builders and house buyers, consume energy and manpower, and achieve artificial shortening and shortening. Construction time, material and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In the following, the technical means adopted by the present invention to achieve the intended purpose of the invention will be further described in conjunction with the accompanying drawings and preferred embodiments of the present invention.

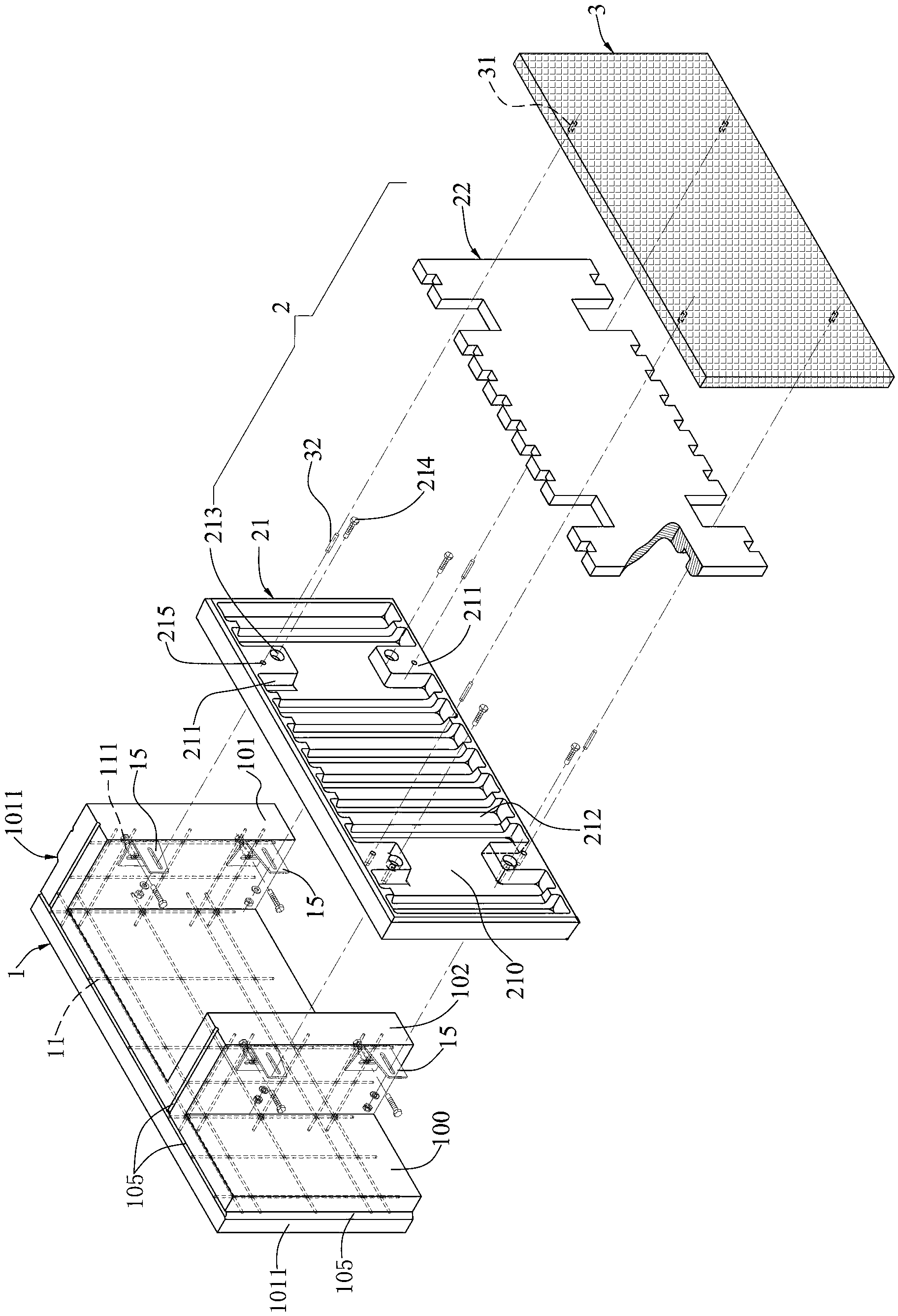

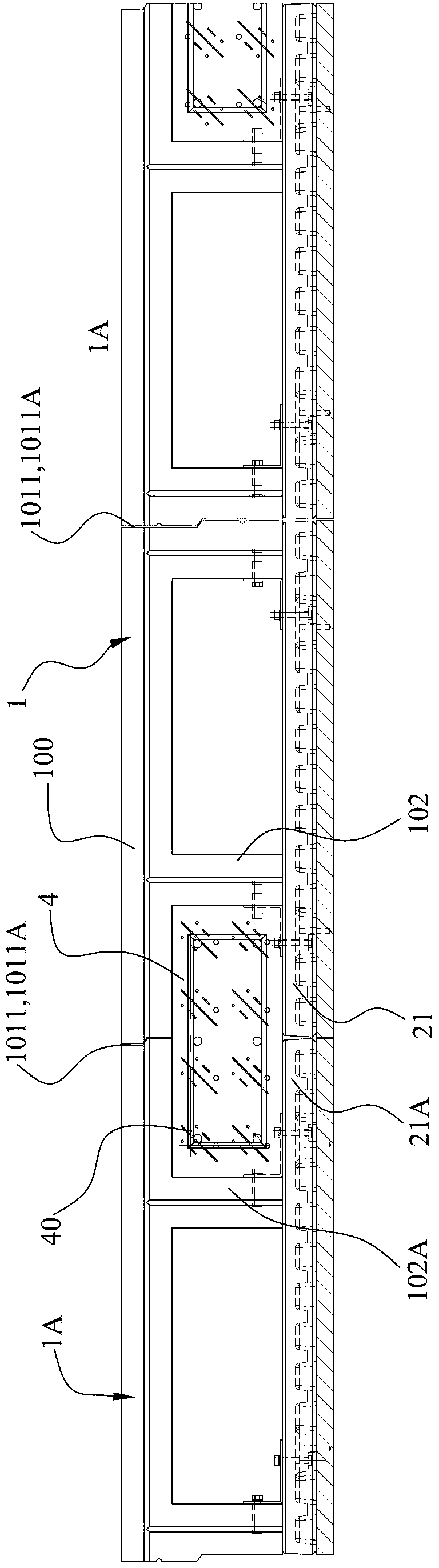

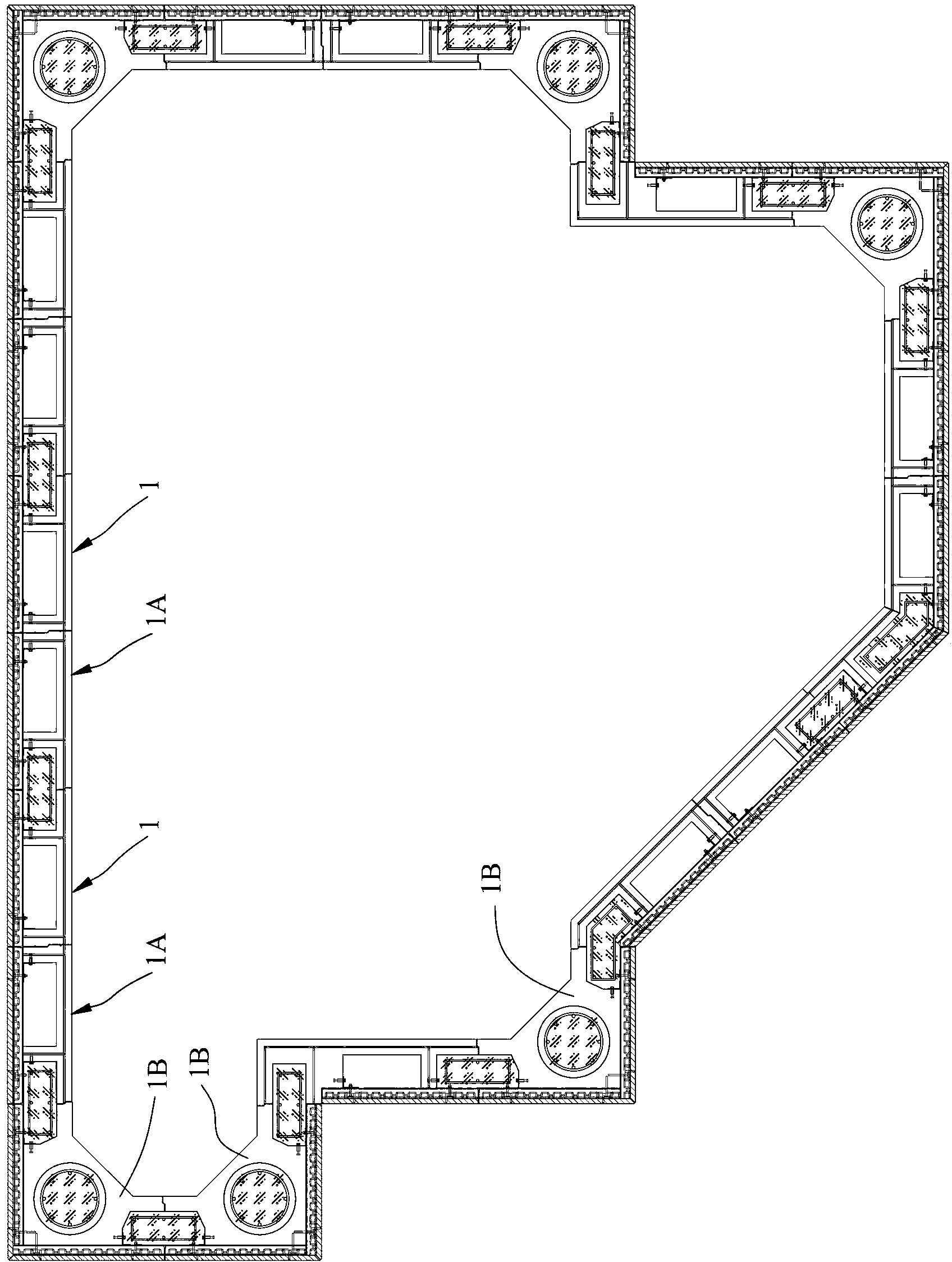

[0048] Please refer to figure 1 As shown, the terracotta brick assembly of the first embodiment provided by the present invention is a kind of terracotta brick, comprising a terracotta block 1, a thermal insulation unit 2, and an exterior trim panel 3, wherein the thermal insulation unit 2 It further includes a thermal insulation partition 21 and a thermal insulation liner 22. The thermal insulation partition 21 is a flat rectangular block formed by pouring clay into a mold and sintering. One side is provided with a concave accommodating groove 210 and several joints. Each joint part 211 is respectively provided with a joint hole 213 for the joint element 214 to pass through and be installed on the ceramic block 1 . The thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com