Pretreatment method capable of eliminating polyhydric alcohol matrix interference in tobacco essence analysis

A technology of matrix interference and tobacco flavor, which is applied to the analysis of materials, material separation, measuring devices, etc., can solve the problems of loss of active ingredients of flavor, loss of chromatographic peak column, heating, etc., achieve no decompression concentration steps, and eliminate matrix interference , The effect of simple experimental equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Filler selection: C18 silica gel filler, specific parameters (particle size: 200-300 mesh, specific surface area: 300-400m 2 / g, carbon content 16-20%).

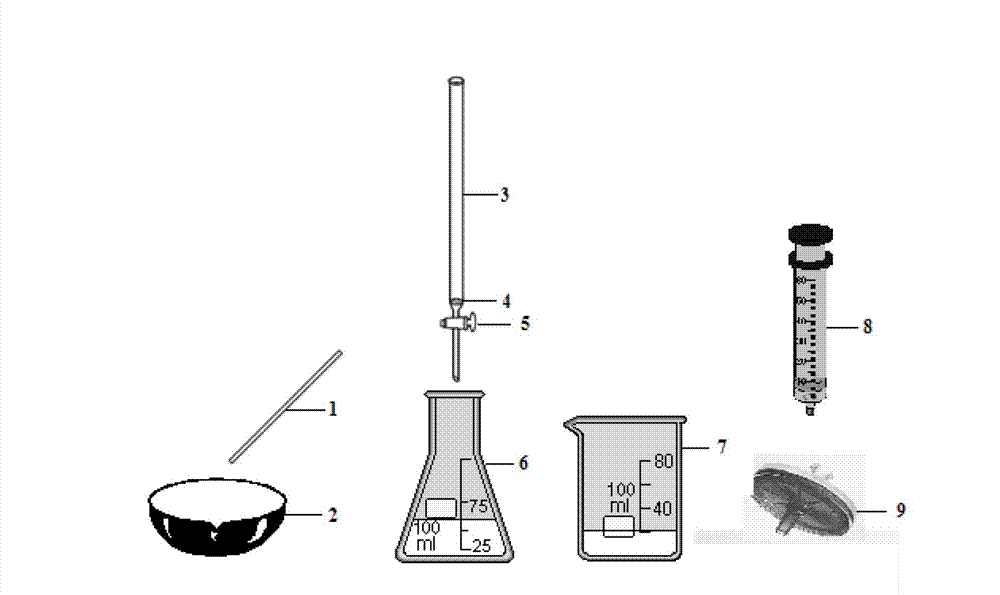

[0039] Selection of the chromatographic column: select the glass material type chromatographic column 3 containing the glass sand separator 4 and the Teflon piston 5, the inner diameter of the column is 1.5 cm, and the column length is 15 cm.

[0040] Sample preparation: Weigh 1.0 g of filler and 0.5 g of flavor sample into glass mortar 2, stir and mix with glass rod 1 to form a homogenate, let it stand for half an hour, and slowly transfer the homogenate to the above-mentioned prepared spare chromatography column , and tuck another ball of absorbent cotton close to the surface of the packing.

[0041] Column packing and sample loading: close the piston 5, weigh 10 grams of C18 silica gel filler and transfer it to the chromatography column 3, add 30 mL of chromatographically pure methanol, stir fully with a glass rod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com