Service life testing platform of control element of heavy-duty car gearbox operating system

A technology for controlling components and life testing, applied in the direction of electrical testing/monitoring, etc., can solve the problems of poor monitoring and control performance, inconvenient operation and installation, and increase the test cost, so as to save the test cost, facilitate operation and maintenance, Simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The content of the present invention will be further described below in conjunction with the drawings, but the actual manufacturing structure of the present invention is not limited to the embodiments shown in the drawings.

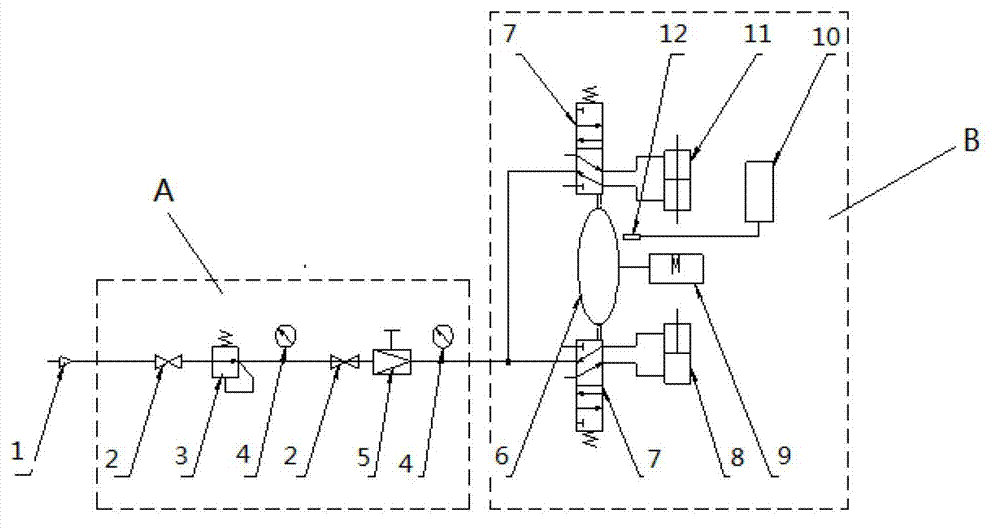

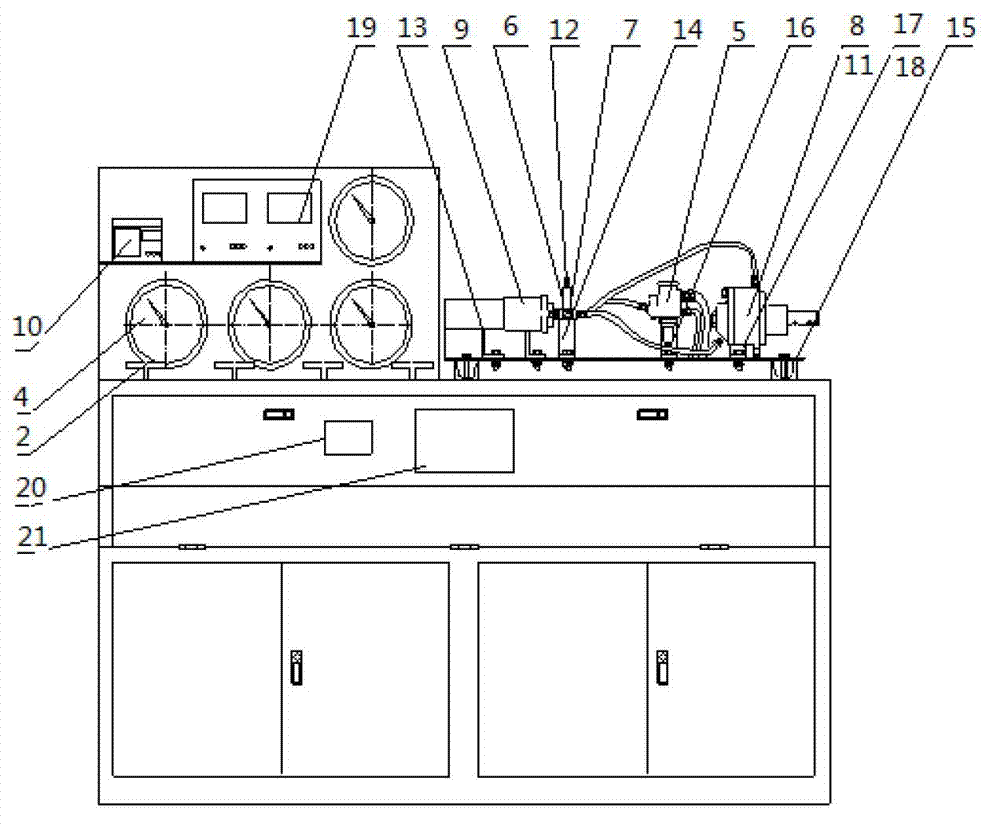

[0015] Referring to the accompanying drawings, the heavy-duty vehicle gearbox steering system control component life test bench according to the present invention includes two parts: a test bench control cabinet body A and a test control component installation platform B. The length, width and height of the control cabinet A of the test bench are 700mm×800mm×1000mm. It is made of carbon steel plate and all the welding points are completed inside the cabinet. The surface of the cabinet is treated with baking varnish, the countertop is made of stainless steel, and there are two detachable structural doors for easy maintenance or observation. The installation plate of the test control component installation platform B is welded by section steel and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com