Modified 4a molecular sieve adsorbent and preparation method thereof

A molecular sieve and adsorbent technology, which is applied in the field of modified 4a molecular sieve adsorbent and its preparation, can solve the problems of expensive raw materials, achieve high utilization rate, increase specific surface area, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

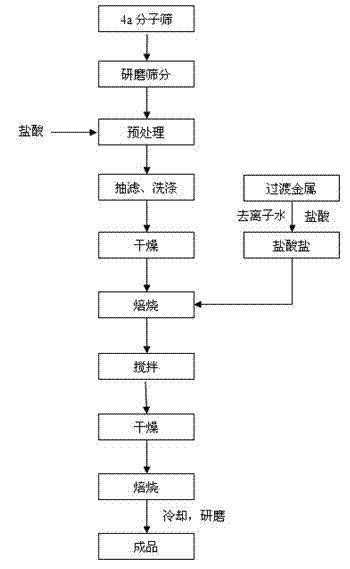

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Modified 4a molecular sieve adsorbent and preparation method thereof, the specific operations are as follows:

[0032] (1) Pulverize the 4a molecular sieve whose chemical composition weight percentage is C 3%, O 42%, Na 3%, Mg 2%, Al 15%, Si 25%, Cl 3%, Ca 2%, Fe 2%, sieve Sorted to a particle size of 20-100 mesh;

[0033] (2) Add 0.5 mol / L hydrochloric acid solution to 4a molecular sieve, the solid-to-liquid ratio is 1:20, then the mixture is stirred at a constant temperature at 70°C for 3 hours, filtered and washed until PH = 7, and dried at 80°C for 6 Hours later, roast for 2 hours, and the roasting temperature is 200°C;

[0034] (3) Weigh 0.11g of ruthenium chloride trihydrate into a beaker, add 3.6ml of deionized water, stir and dissolve to prepare a ruthenium chloride solution, then add 0.8ml of hydrochloric acid solution with a concentration of 0.5mol / L, and then add The 2g 4a molecular sieve after roasting, after stirring at constant temperature ...

Embodiment 2

[0039] Embodiment 2: Modified 4a molecular sieve adsorbent and preparation method thereof, the specific operations are as follows:

[0040] (1) Pulverize the 4a molecular sieve with chemical composition weight percentage of C 5%, O 52%, Na2%, Mg 2%, Al 10%, Si 24%, Cl 2%, Ca 2%, Fe 2%, and sieve To a particle size of 20-100 mesh;

[0041] (2) Add 2mol / L hydrochloric acid solution to 4a molecular sieve, the solid-to-liquid ratio is 1:10, then the mixture is stirred at a constant temperature at 95°C for 2 hours, filtered and washed until PH = 7, and dried at 70°C for 7 hours Afterwards, roasting for 3 hours, the roasting temperature is 250 ℃;

[0042] (3) Weigh 0.23g of ruthenium chloride trihydrate and put it into a beaker, add 2.8ml of deionized water, stir and dissolve to prepare a ruthenium chloride solution, then add 1.6ml of hydrochloric acid solution with a concentration of 5mol / L, and then add roasting The final 2g 4a molecular sieve was stirred at constant temperature...

Embodiment 3

[0047] Embodiment 3: Modified 4a molecular sieve adsorbent and preparation method thereof, the specific operations are as follows:

[0048] (1) The weight percentage of the chemical composition is C 6%, O 48%, Na 3%, Mg 2%, Al 15%, Si 22%, Cl 2%, Ca 2%, Fe 1% 4a molecular sieves, and sieve To a particle size of 20-100 mesh;

[0049] (2) Add 8mol / L hydrochloric acid solution to 4a molecular sieve, the solid-to-liquid ratio is 1:30, then the mixture is stirred at a constant temperature at 60°C for 4 hours, filtered and washed until PH=7, and dried at 90°C for 4 hours Afterwards, roast for 1 hour at a roasting temperature of 300°C;

[0050] (3) Weigh 0.1g of ferric chloride hexahydrate into a beaker, add 4ml of deionized water, stir and dissolve to prepare ferric chloride solution, then add 0.4ml of hydrochloric acid solution with a concentration of 8mol / L, and then add 2g of 4a molecular sieves, stirred at constant temperature for 4 hours, and left to stand for 8 hours;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com