Device and method of enhancing sludge stability and sludge digestion liquid treatment

A technology of sludge digestion liquid and sludge, which is applied in the field of processing objects, can solve the problems affecting the water quality of sewage treatment plants, etc., and achieve the effects of saving equipment costs and floor space, high degree of equipment integration, and easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

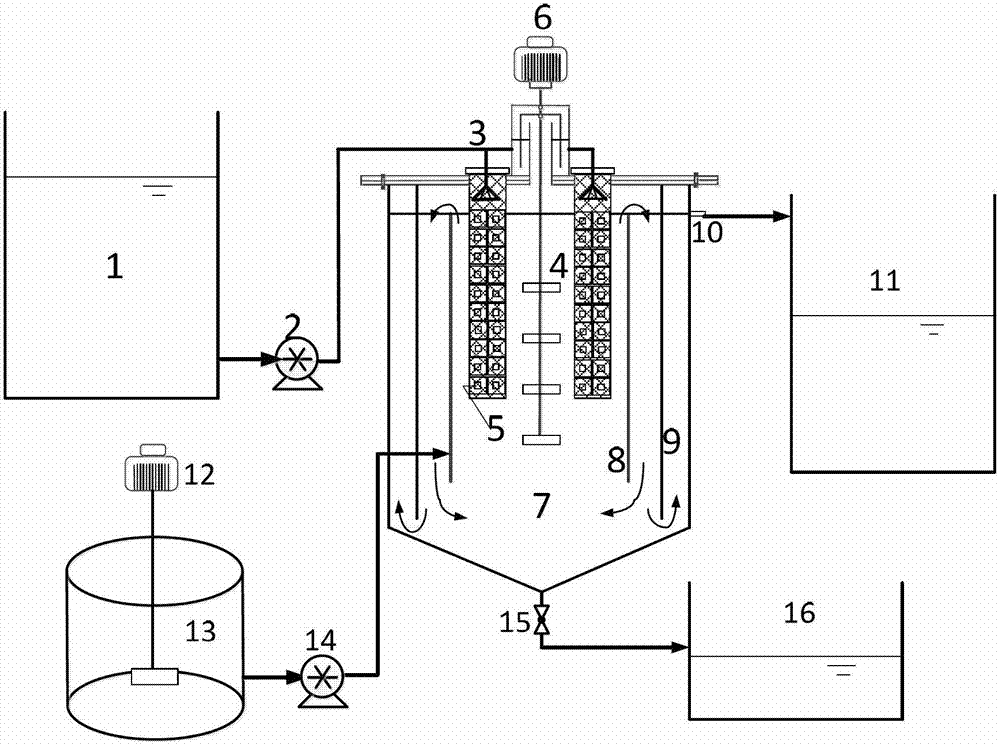

[0030] Embodiment 1: The water inlet pump is in the open state, and the short-range nitrification effluent of the sludge digestion liquid continuously enters the hanging packing column through the water inlet pump and the water distribution pipe, contacts with the biosphere packing and spreads around. The flow rate of the water inlet pump is 0.5L / hour, and the hydraulic retention time HRT is 20 hours. Control the sludge residence time SRT of the reactor to 20 days, open the sludge discharge valve at the bottom every day to discharge 0.5L of mixed sludge, then turn on the sludge inlet pump, and pass the mixed sludge that has undergone anaerobic pretreatment into the integrated reactor. The mud volume is 0.5L. Put the above mixed sludge into the sludge pretreatment tank for anaerobic fermentation, the sludge residence time SRT is 2 days, and the second agitator rotates continuously.

Embodiment 2

[0031] Embodiment 2: The water inlet pump is in the open state, and the short-range nitrification effluent of the sludge digestion liquid continuously enters the hanging packing column through the water inlet pump and the water distribution pipe, contacts with the biosphere packing and spreads around. The flow rate of the water inlet pump is 0.4L / hour, and the hydraulic retention time HRT is 25 hours. Control the sludge residence time SRT of the integrated reactor to 25 days, open the sludge discharge valve at the bottom every day to discharge 0.4L of mixed sludge, then turn on the sludge inlet pump, and pass the mixed sludge that has undergone anaerobic pretreatment into the integrated reactor , The volume of mud entry is 0.4L. Put into above-mentioned mixed sludge in the sludge pretreatment tank and carry out anaerobic fermentation, the sludge residence time SRT is 2 days, and the second agitator rotates continuously.

[0032] The test proves that the mixed sludge of primar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com