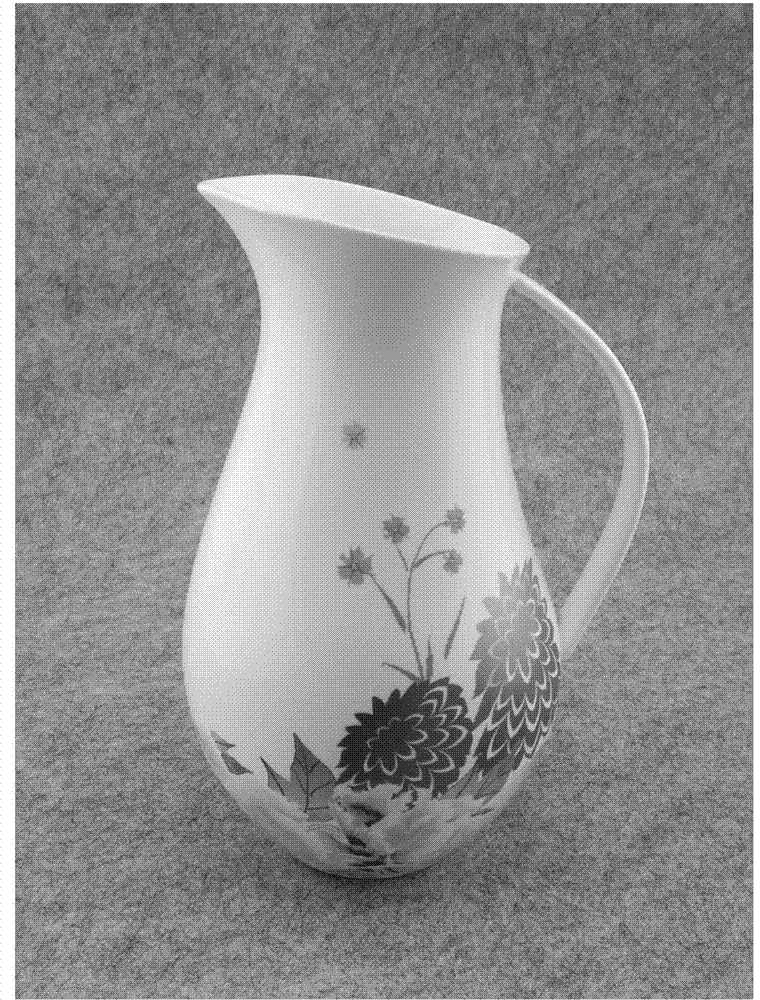

High-calcium ceramic and preparation process thereof

A preparation process and a technology for ceramics, applied in the field of high calcium ceramics and the preparation process thereof, can solve the problems of increasing the difficulty of firing, easy to burn and crack, and achieve the effects of easy quality control, energy saving and production cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Weigh 36 parts of raw material clay, 11 parts of potassium feldspar, 26 parts of quartz, 22 parts of calcite, and 5 parts of bentonite;

[0035] 2) Grinding in stages: ① Grind the quartz to 10-15 μm; ② Mix the ground quartz with potassium feldspar, calcite or stalactite, and bentonite, add 45% of the mass of water, and ball mill to 250 mesh; The clay is separately slurried, with a moisture content of 30%; ④Then mix the materials obtained in ② and ③ evenly;

[0036] 3) Pass through a 180-mesh sieve, remove iron with a strength of 22,000 gauss, press filter and dewater to make the water content of the filter mud ≤ 24%, refine under a vacuum of 0.096MPa, put it in storage for 7 days, refine again, send it to molding, and make a billet body;

[0037] 4) After trimming, watering, drying, and passing the inspection, glaze is applied, fired in a kiln, and fired at 1200°C for 60 minutes;

[0038] 5) Inspect the fired products of high-calcium ceramics. After the qualified ...

Embodiment 2

[0042] 1) Weigh 25 parts of raw material clay, 15 parts of potassium feldspar, 25 parts of quartz, 25 parts of stalactite, and 10 parts of bentonite;

[0043] 2) Grinding in stages: ① Grind the quartz to 10-15 μm; ② Mix the ground quartz with potassium feldspar, calcite or stalactite, and bentonite, add 50% of the mass of water, and ball mill to 200 mesh; The clay is separately slurried, with a moisture content of 30%; ④Then mix the materials obtained in ② and ③ evenly;

[0044] 3) Pass through a 160-mesh sieve, remove iron with a strength of 20,000 gauss, press filter and dewater to make the water content of the filter mud ≤ 24%, refine under a vacuum of 0.095MPa, put it in storage for 8 days, refine again, send it to molding, and make a billet body;

[0045] 4) After trimming, watering, drying, and passing the inspection, glaze is applied, fired in a kiln, and fired at 1220°C for 50 minutes;

[0046] 5) Inspect the fired products of high-calcium ceramics. After the qualif...

Embodiment 3

[0050] 1) Weigh 20 parts of raw material clay, 2 parts of potassium feldspar, 28 parts of quartz, 20 parts of stalactite, and 2 parts of bentonite;

[0051] 2) Grinding in stages: ① Grind the quartz to 10-15 μm; ② Mix the ground quartz with potassium feldspar, calcite or stalactite, and bentonite, add 45% of the mass of water, and ball mill to 200 mesh; The clay is separately slurried, with a moisture content of 33%; ④Then mix the materials obtained in ② and ③ evenly;

[0052] 3) Pass through a 200-mesh sieve, remove iron with 20,000 gauss strength, press filter and dewater to make the water content of the filter mud ≤ 24%, refine under a vacuum degree of 0.098MPa, put it in storage for 10 days, refine again, send it to molding, and make a billet body;

[0053] 4) After trimming, watering, drying, and passing the inspection, glaze is applied, fired in a kiln, and fired at 1240°C for 40 minutes;

[0054] 5) Inspect the fired products of high-calcium ceramics. After the quali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com