A kind of propylene polymer and its preparation method and application

A technology for polymerizing propylene polymers and olefins, applied in the field of propylene polymers and their preparation, can solve problems such as film tearing, hindering the diffusion of polymerized monomers, adverse effects on production efficiency, etc., and achieve the effect of ensuring the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The present invention provides a kind of preparation method of propylene polymer, and this method comprises in gas phase polymerization reactor, under the condition of olefin gas phase polymerization, propylene, ethylene and selected from C 4 -C 8 The alpha-olefin is contacted with an olefin polymerization catalyst system.

[0017] In the present invention, the propylene polymer refers to propylene, ethylene and C 4 -C 8 A random copolymer formed by copolymerizing an α-olefin, wherein the α-olefin can be one type of α-olefin or two or more α-olefins.

[0018] According to the method of the present invention, the olefin polymerization catalyst system may be various catalyst systems commonly used in the art that can catalyze the organic stereopolymerization of propylene. Generally, the olefin polymerization catalyst system comprises a solid component, an external electron donor compound and an organoaluminum compound, the solid component comprising a support and a tita...

Embodiment 1

[0088] This example serves to illustrate the propylene polymer and the process for its preparation according to the present invention.

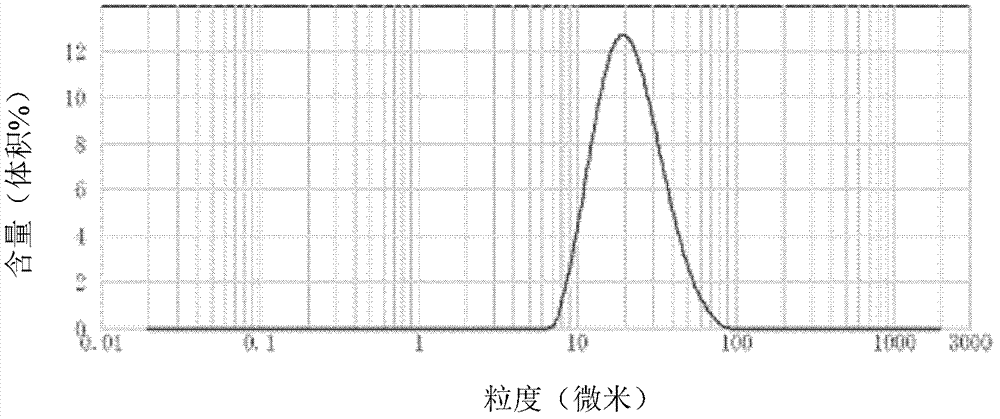

[0089] Catalyst solid component (commercially purchased from Beijing Aoda Petrochemical Co., Ltd.) is sieved so that the particle size of the obtained solid component is 8-100 microns, and the particle size of the solid component in the range of 14-30 microns The amount is 80% by volume. Such as figure 1 As shown, the obtained particle size distribution curve of the solid component is a unimodal distribution.

[0090] The solid component uses magnesium chloride as a carrier, wherein, based on the total amount of the solid component, the content of titanium in terms of elements is 2.5% by weight, and the content of di-n-butyl terephthalate is 10% by weight.

[0091] Continuously feed the catalyst solid component into 50m at 0.63kg / h 3 In the continuous horizontal stirred bed gas-phase reactor, add triethylaluminum continuously with the pump...

Embodiment 2

[0097] This example serves to illustrate the propylene polymer and the process for its preparation according to the present invention.

[0098] Adopt the same method as Example 1 to prepare propylene polymer, the difference is that the pressure in the reactor is 2.4MPa, the temperature in the reactor is 60 ° C, and the hydrogen / propylene molar ratio (H 2 / C 3 ) is 0.013.

[0099]The polymer obtained by polymerization is granular without agglomeration, and there is no phenomenon that the material discharge pipe of the reactor is blocked when the material is discharged. The composition and properties of the propylene polymers prepared are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com