Method for preparing composite hydrogel of sodium alginate and artemisia desertorum seed gum

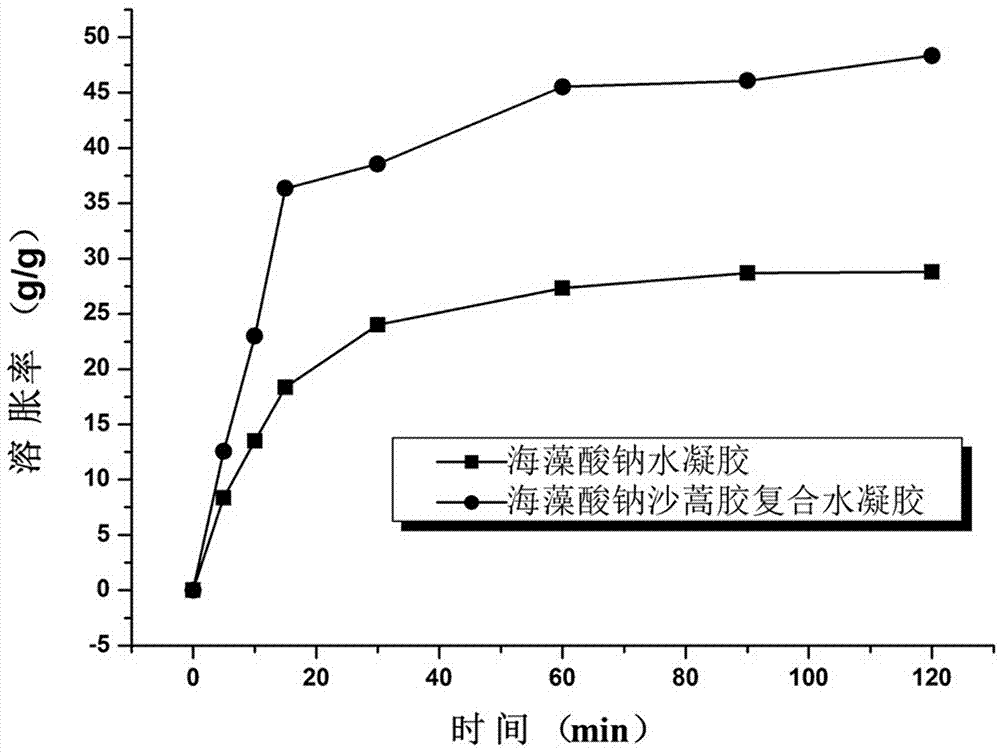

A technology of composite hydrogel and sodium alginate, applied in the fields of biological materials and tissue engineering materials, can solve the problems of inability to form a uniform gel and application difficulties of artemisia gum, and achieve enhanced water absorption and mechanical properties, low cost, The effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

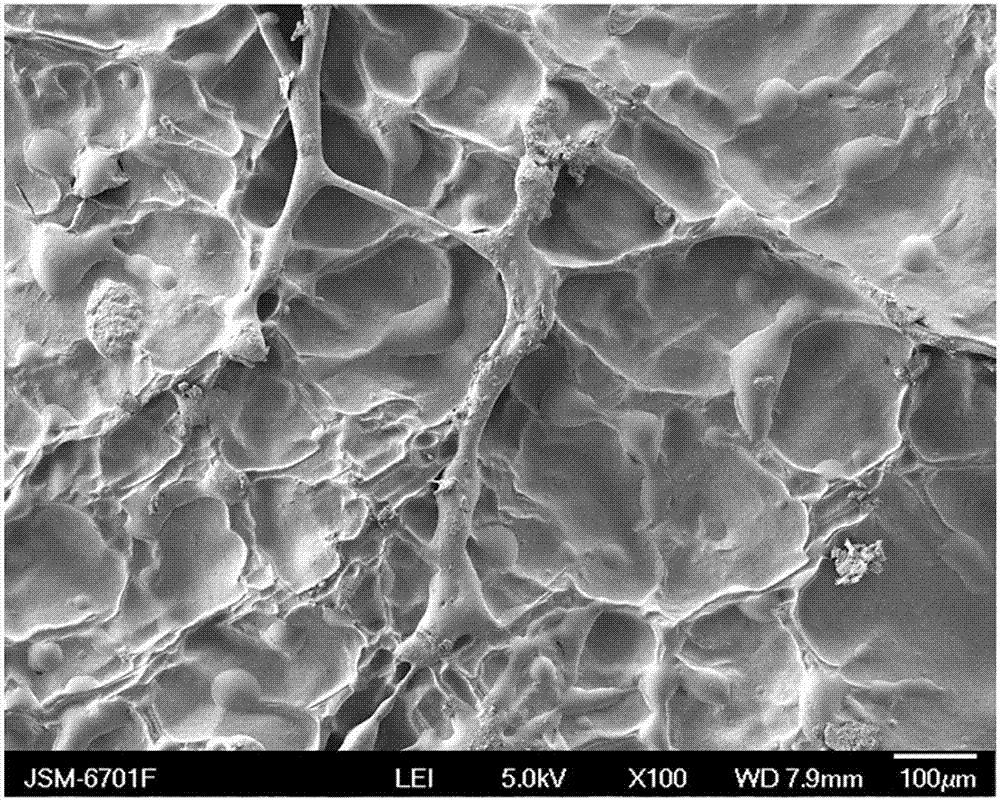

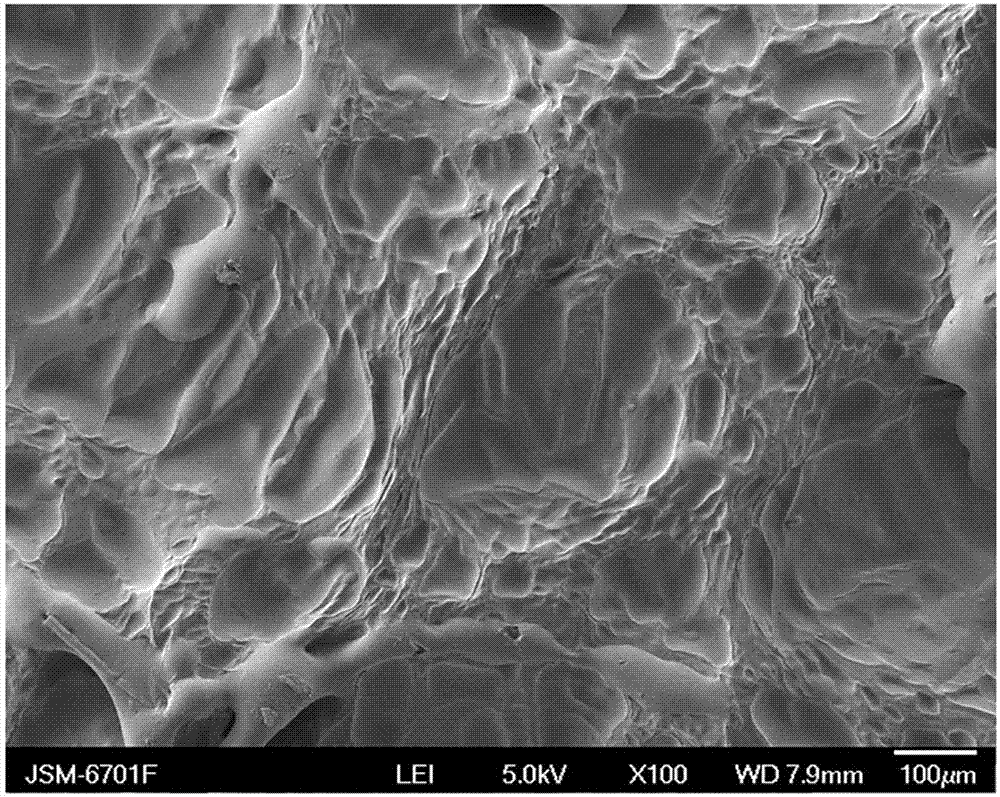

Image

Examples

Embodiment 1

[0029] (1) Measure Na at room temperature 2 CO 3 Solution (0.2 mol / L) 100 mL, add 20 mL sodium polystyrene sulfonate (4 g / L), stir well and pour 100 mL CaCl 2 solution (0.2 mol / L), stirred at 1500 rpm for 10 min, and then centrifuged at 4500 rpm to collect the precipitate; the precipitate was washed three times in acetone and distilled water successively; at 0.07 Suction filtration under MPa; collect the filter cake and dry at 60°C for 8 hours to obtain microporous calcium carbonate;

[0030] (2) Weigh 0.03 g of microporous calcium carbonate, add it to sodium alginate solution (the mass ratio of sodium alginate to water is 1:100), and stir evenly to obtain a mixed solution of microporous calcium carbonate-sodium alginate;

[0031] (3) Weigh 0.15g of artemisia gum, add it to 15mL of absolute ethanol, stir evenly, and drop it into the mixed solution of microporous calcium carbonate-sodium alginate at a speed of 1500 rpm at a rate of 10 drops / min , to obtain a mixed s...

Embodiment 2

[0035] (1) Measure Na at room temperature 2 CO 3 Solution (0.3 mol / L) 100 mL, add 20 mL sodium polystyrene sulfonate (3 g / L), stir well and pour 100 mL CaCl 2 solution (0.3 mol / L), stirred at 2000 rpm for 5 min, and then centrifuged at 3500 rpm to collect the precipitate; the precipitate was washed three times in acetone and distilled water successively, at 0.06 Suction filtration under the condition of MPa, the collected filter cake was dried at 60°C for 7 hours to obtain microporous calcium carbonate;

[0036] (2) Weigh 0.04 g of microporous calcium carbonate, add it to sodium alginate solution (the mass ratio of sodium alginate to water is 1:200), and stir evenly to obtain a mixed solution of microporous calcium carbonate-sodium alginate;

[0037] (3) Weigh 0.075g of artemisia gum, add it into 15mL of absolute ethanol and stir evenly, then drop it into the mixed solution of microporous calcium carbonate-sodium alginate at a speed of 15 drops / min at 1500 rpm , to...

Embodiment 3

[0041] (1) Measure Na at room temperature 2 CO 3 Solution (0.3 mol / L) 100 mL, add 20 mL sodium polystyrene sulfonate (2 g / L), stir well and pour 100 mL CaCl 2 solution (0.3 mol / L), stirred at 1800 rpm for 8 min, and then centrifuged at 4000 rpm to collect the precipitate; the precipitate was washed three times in acetone and distilled water successively, and the Under the condition of suction filtration, the collected filter cake was dried at 60°C for 6 hours to obtain microporous calcium carbonate;

[0042] (2) Weigh 0.05 g of microporous calcium carbonate, add it into sodium alginate solution (the mass ratio of sodium alginate to water is 1:50), and stir evenly to obtain a mixed solution of microporous calcium carbonate-sodium alginate;

[0043] (3) Weigh 0.045g of artemisia gum, add it to 15mL of absolute ethanol, stir evenly, and drop it into the mixed solution of microporous calcium carbonate-sodium alginate at a speed of 20 drops / min at 1800 rpm , to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Storage modulus | aaaaa | aaaaa |

| Storage modulus | aaaaa | aaaaa |

| Storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com