Steam Rankine-low boiling point working medium Rankine combined cycle power generation device

A low-boiling-point working fluid and Rankine cycle technology, which is applied in the direction of steam engine installation, steam generation, combined combustion mitigation, etc., to achieve the effect of saving equipment investment, improving thermal efficiency, avoiding pollution and soda loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

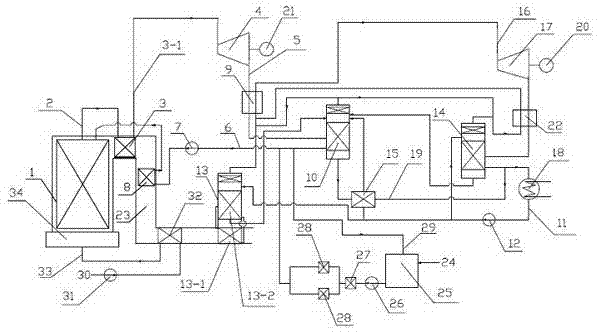

[0044] Such as figure 1 As shown, a steam Rankine-low boiling point working medium Rankine combined cycle power generation device, the device includes a steam Rankine cycle and a low boiling point working medium Rankine cycle system, specific embodiments are as follows:

[0045] The ammonia steam Rankine cycle uses a mixture of ammonia and water.

[0046] The steam Rankine cycle refers to the saturated steam 2 coming out of the boiler body 1, passing through the heater 3 to form superheated steam 3-1, and sending it into the steam turbine 4 to drive the steam generator 21 to generate electricity; the exhaust steam 5 coming out of the steam turbine 4 passes through Heater 9 and condensing evaporator 10 form condensed water 6, and condensed water 6 passes through feed water pump 7, feed water heater 8, and boiler body 1 to generate saturated steam, thereby forming a steam Rankine cycle.

[0047] In the ammonia vapor Rankine cycle, the condensation evaporator 10, the cooling ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com